Sensing load damp-changing or controllable sensing load damp-changing shock mitigation system

A shock absorption system and variable damping technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the impact of vehicle comfort, it is difficult to achieve the shock absorption effect, and the damping strength cannot be adjusted accordingly. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

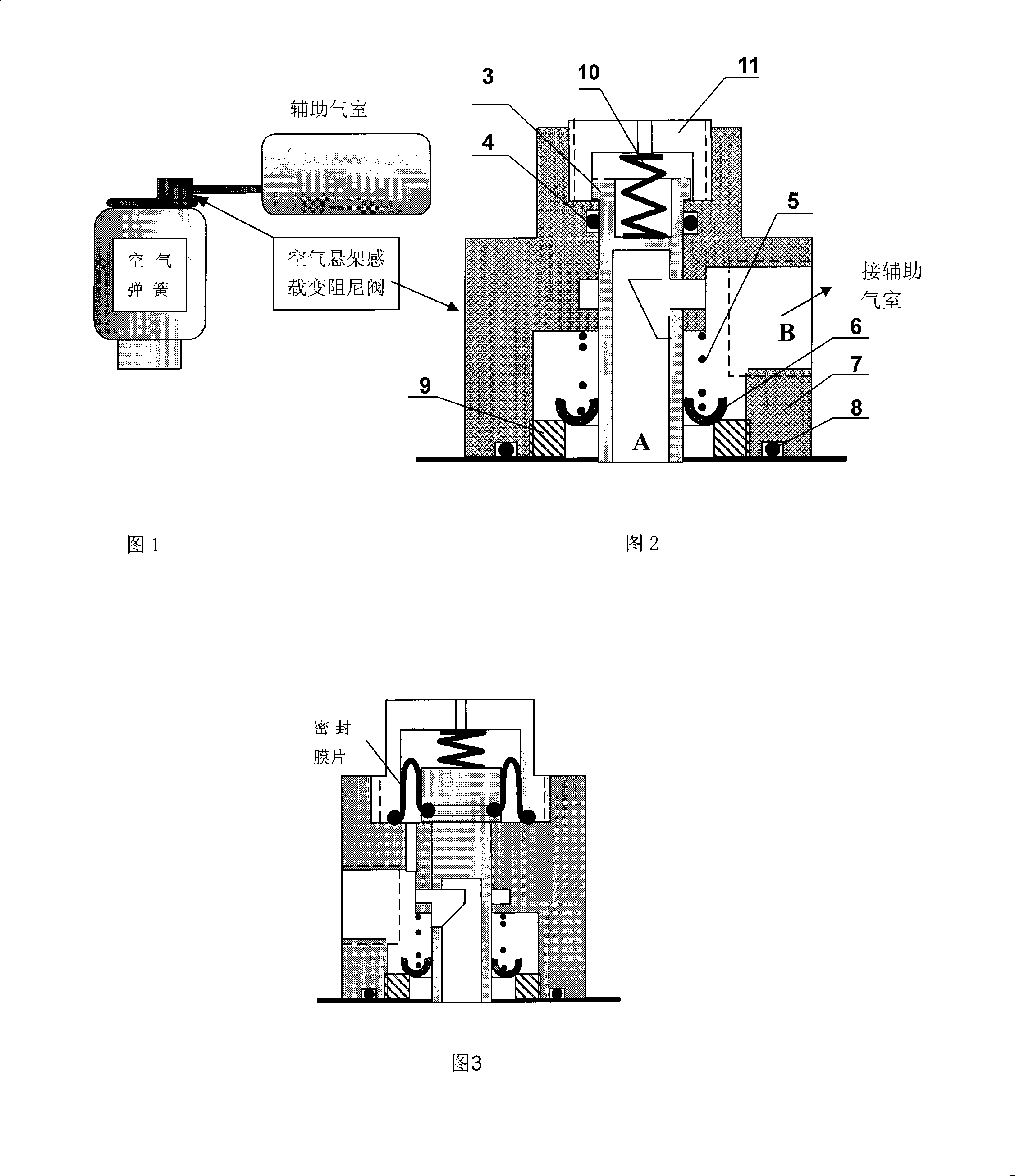

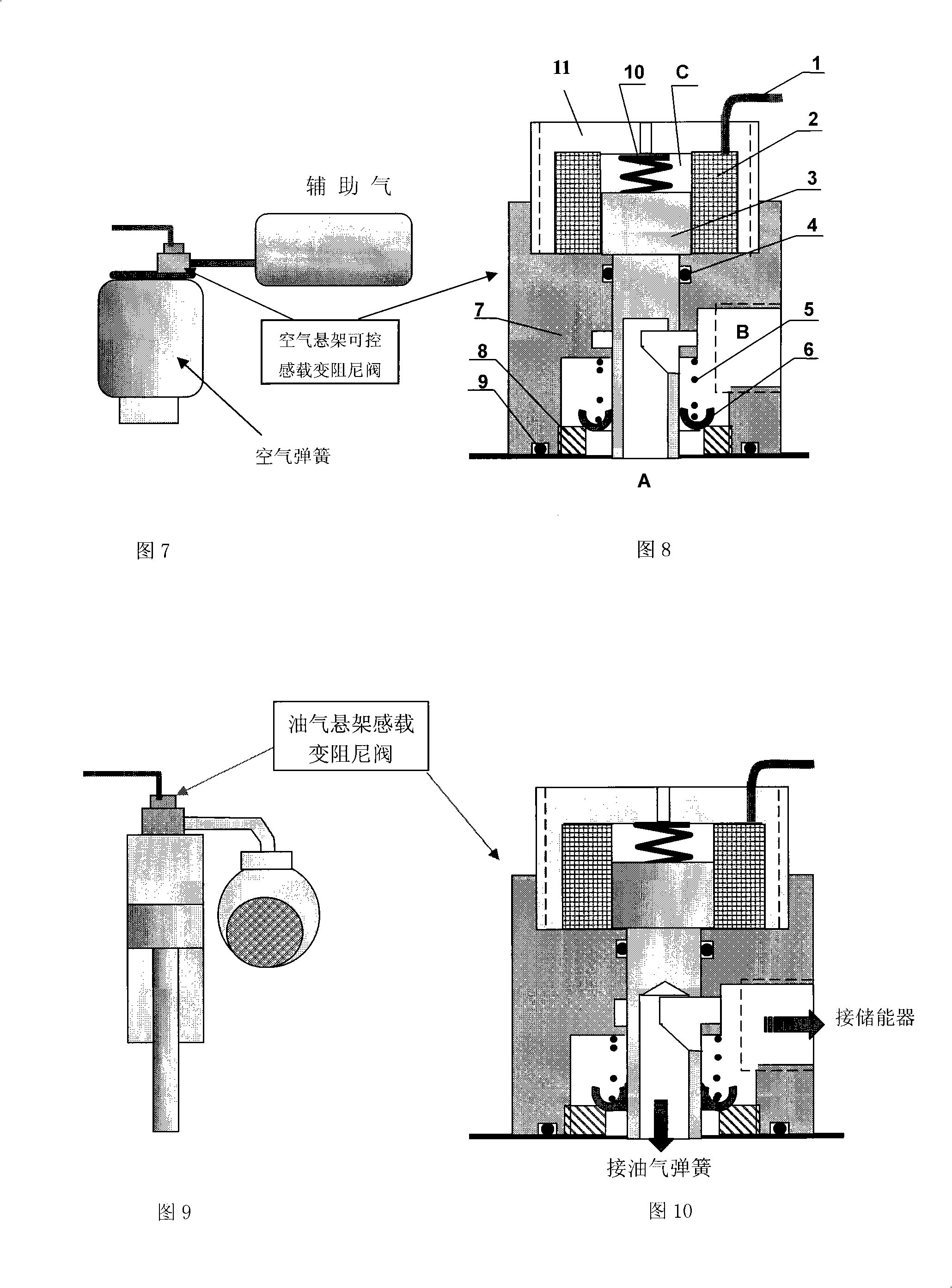

[0016] The load-sensing variable damping system for air suspension, as shown in Figure 1, consists of an air spring, an auxiliary air chamber and a load-sensing variable damping valve. The specific structure of the load-sensing variable damping valve is shown in Figure 2. The A chamber of the load-sensing variable damping valve communicates with the air spring, and the B chamber communicates with the auxiliary air chamber. Load-sensing variable damping valve consists of damping valve core 3, sealing ring 4, one-way valve return spring 5, one-way valve 6, valve body 7, one-way valve port 8, sealing ring 9, control spring 10 and valve cover 11 .

[0017] The sealing ring 4 in the load-sensing damping valve can be replaced by a sealing diaphragm, as shown in Figure 3, the advantage of this replacement is that it can reduce the friction of the sealing ring and improve the sensitivity of load control.

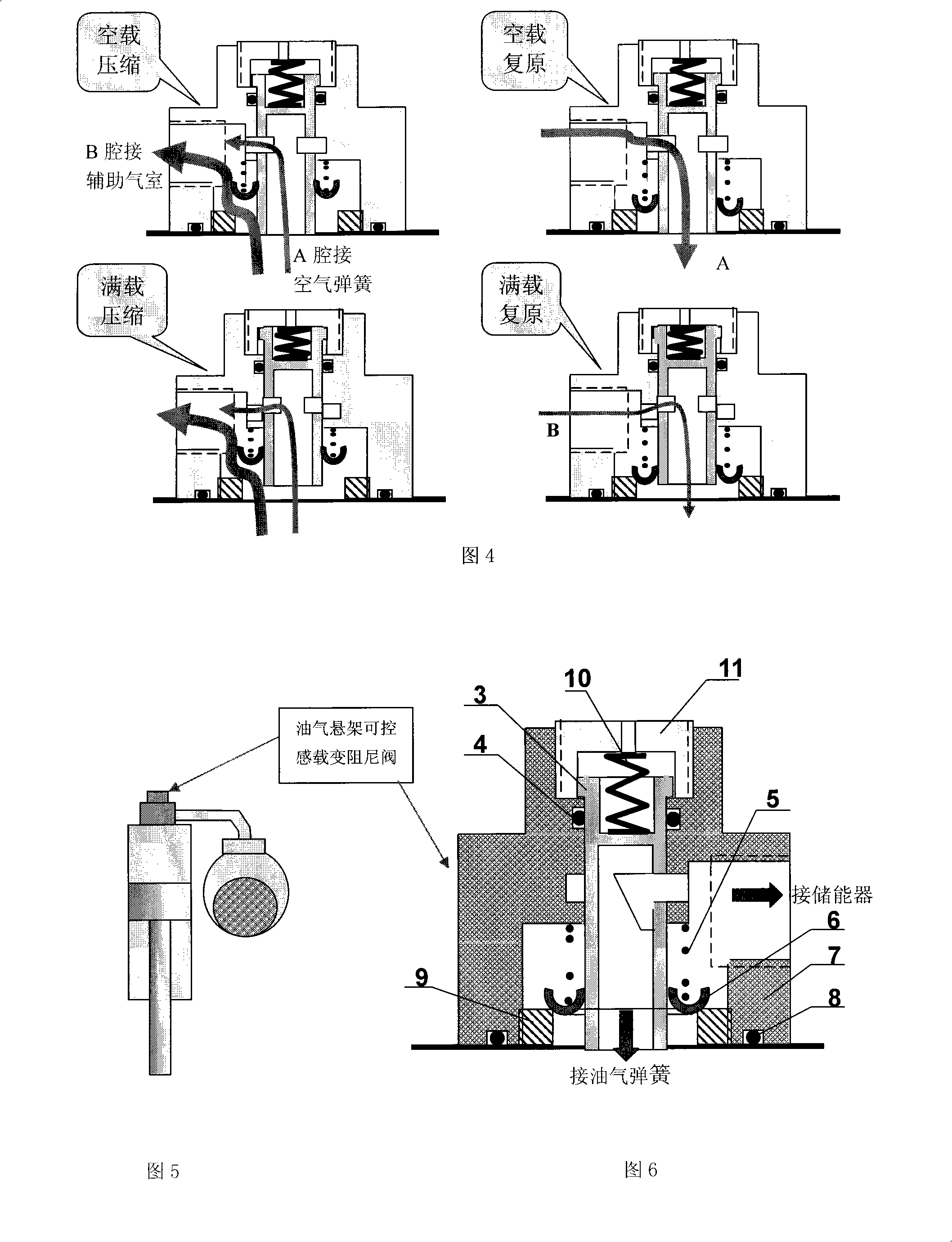

[0018] The characteristic of the load-sensing variable damping system for air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com