Automatic control system of sintered plant mixture making according to chemical composition

An automatic control system, chemical composition technology, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

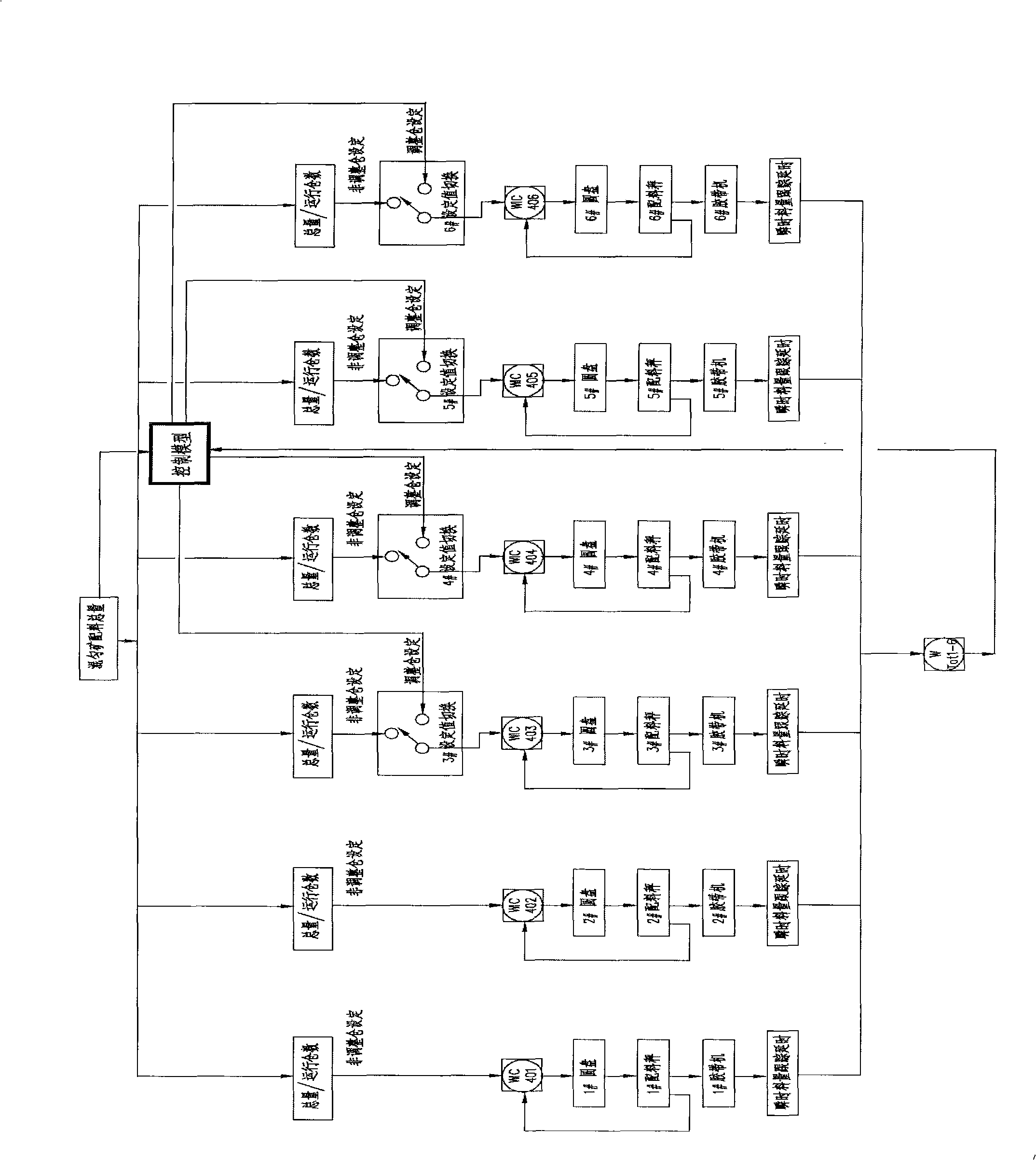

[0082] The specific embodiments of the present utility model will be described below with reference to the accompanying drawings.

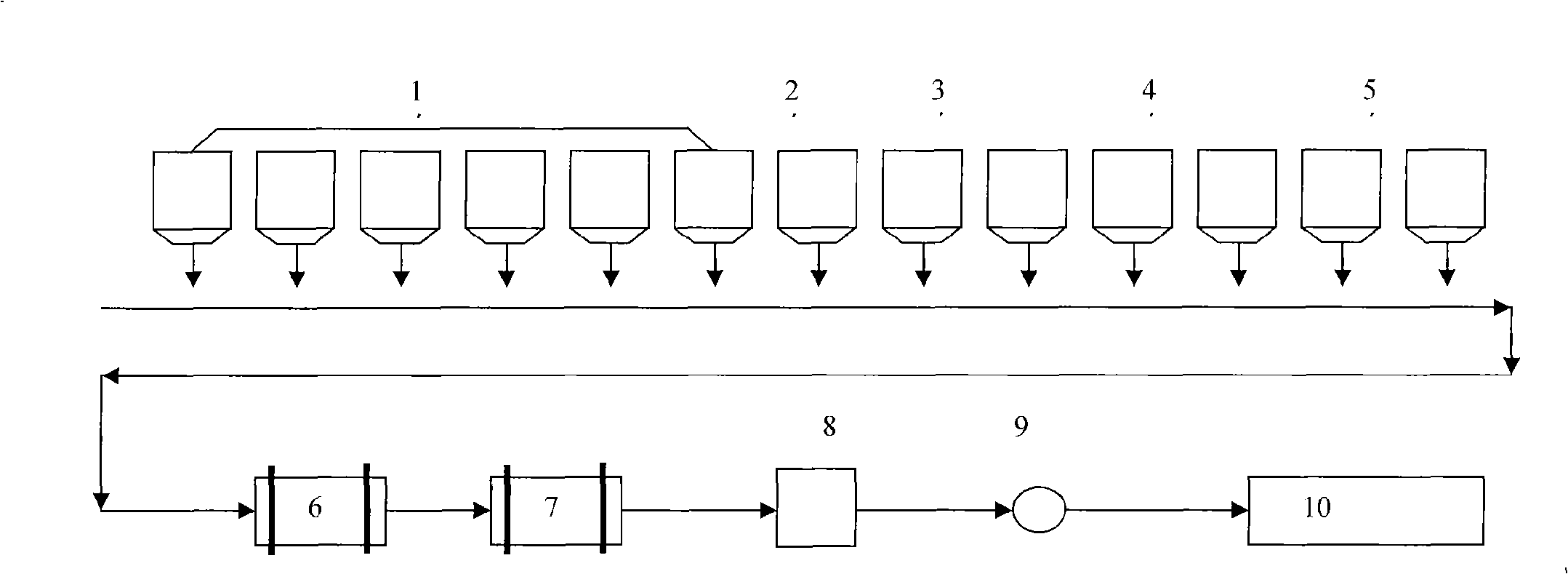

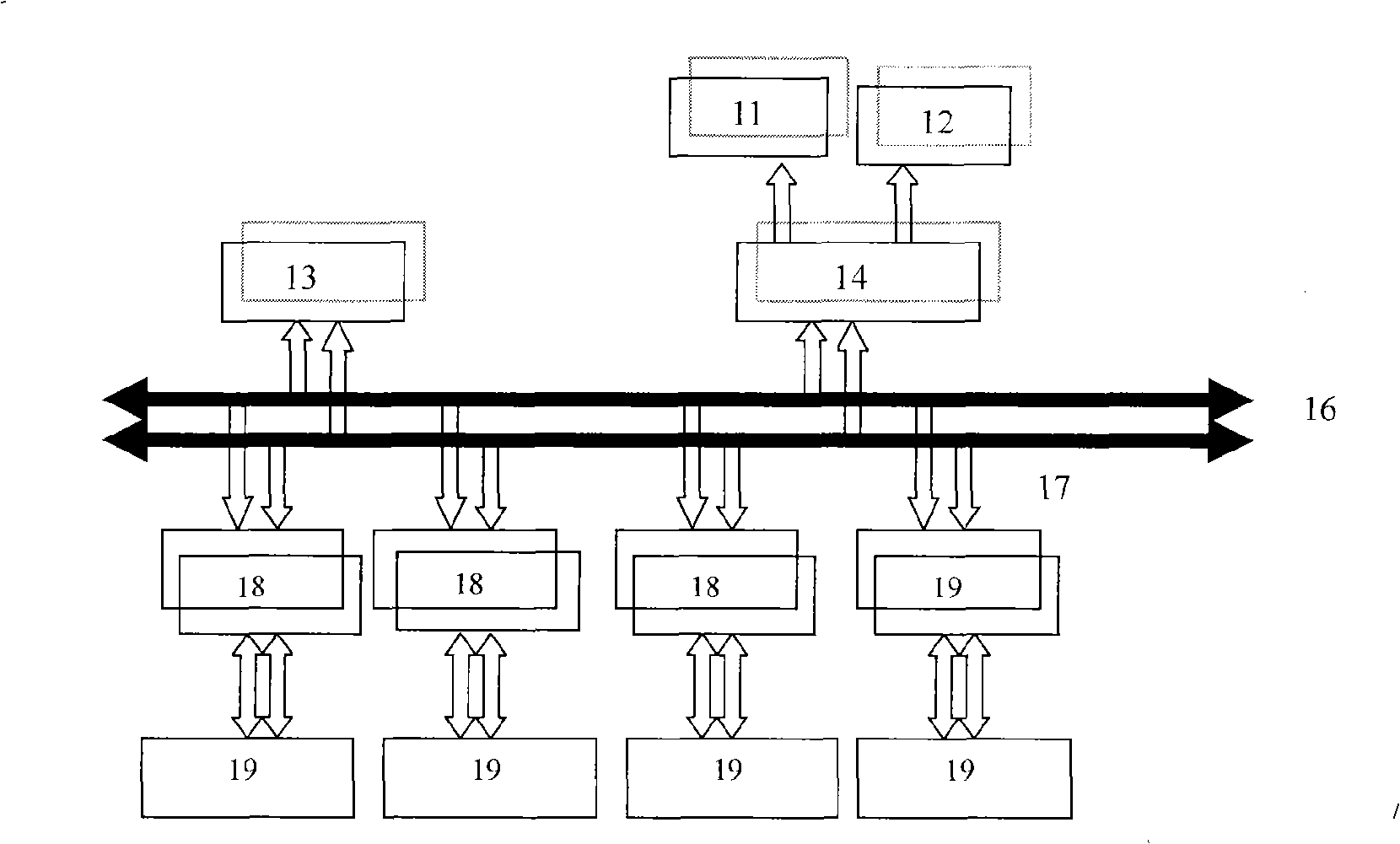

[0083] like figure 1 , 2 As shown, the sintering plant of the present invention is an automatic control system for proportioning chemical components, including a basic automation level L1 and a process automation level L2 to form a secondary control system network, data network communication, and parameter acquisition and processing devices. The stage L1 is equipped with a ratio setting program and a control calculation model.

[0084] like figure 2 As shown, the basic automation level L1 adopts a standard double-ring Ethernet structure, and consists of standard double-ring Ethernet 16, 17, man-machine interface / programmer 13, PC server 14 connected with the standard double-ring Ethernet 16, 17 respectively The central processing unit 18 of the PLC, the engineer workstation 11 connected with the PC server 14, the man-machine interface 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com