Junction box to be mounted on motor vehicle

A technology for motor vehicles and junction boxes, applied in the field of junction boxes, can solve problems such as the heat influence of internal circuit board relays, achieve the effects of reducing costs and assembly steps, preventing size increase, and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

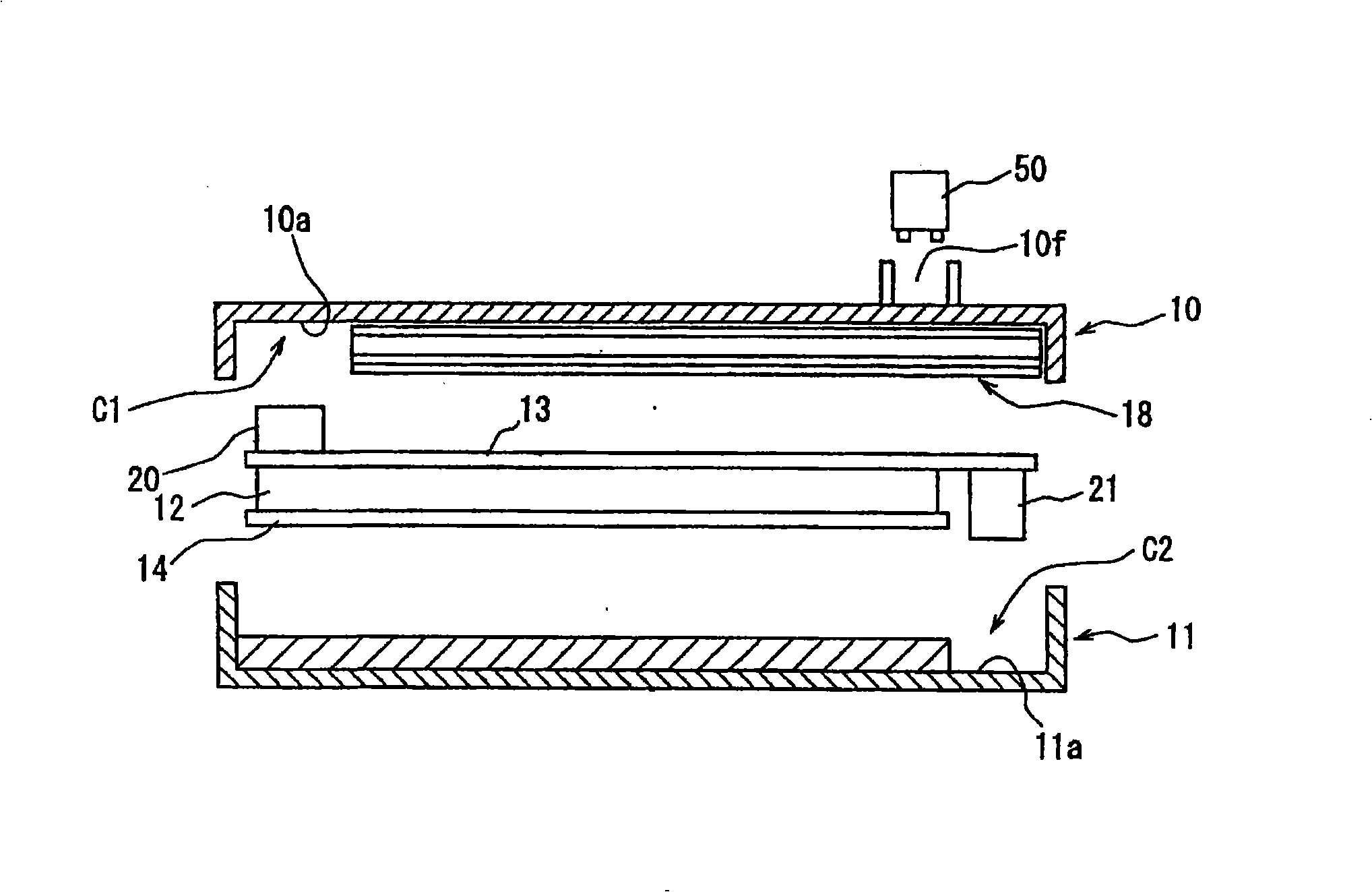

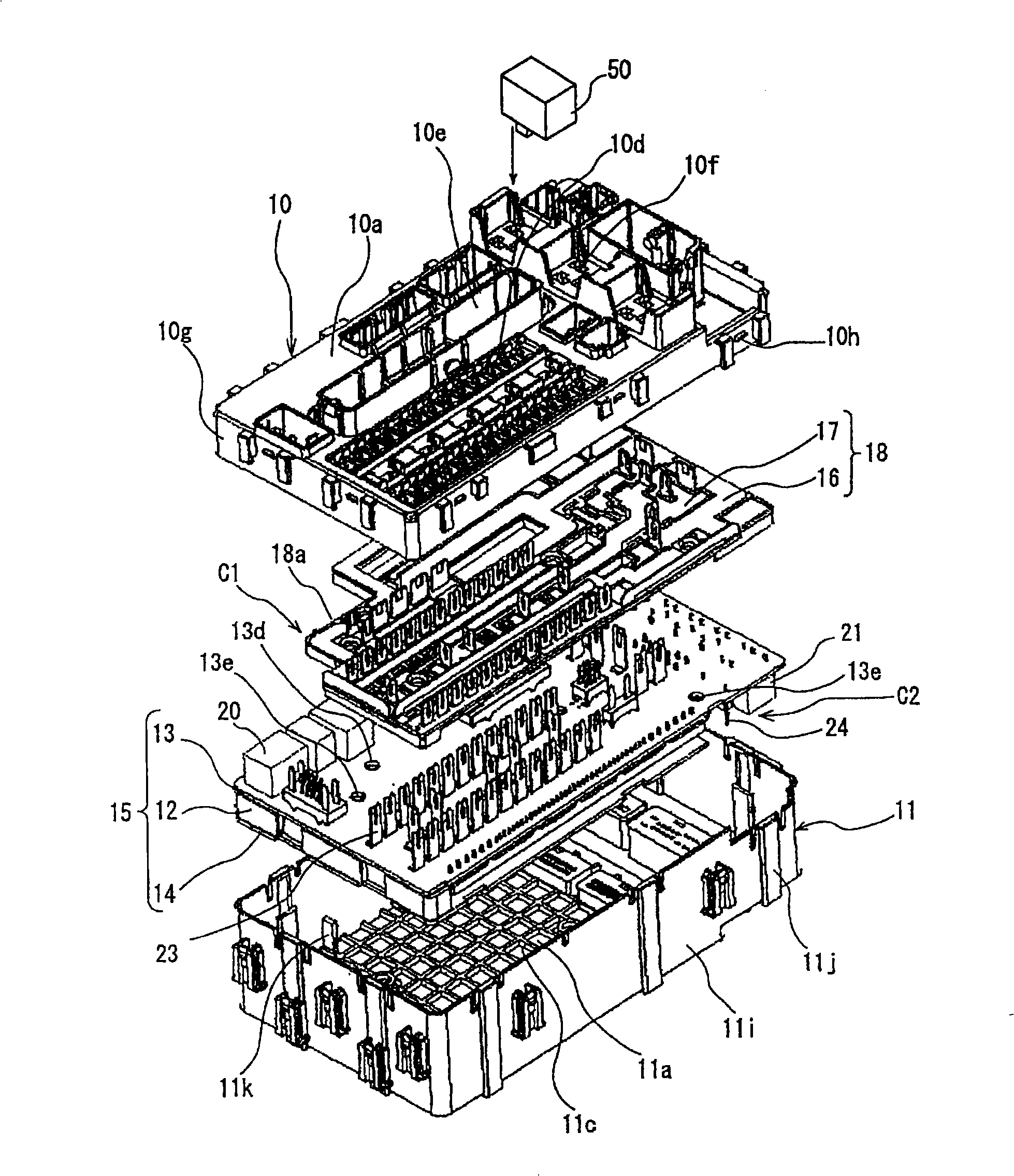

[0035] now refer to Figures 1 to 7 , an embodiment of a junction box to be mounted on a motor vehicle according to the present application will be described in detail below.

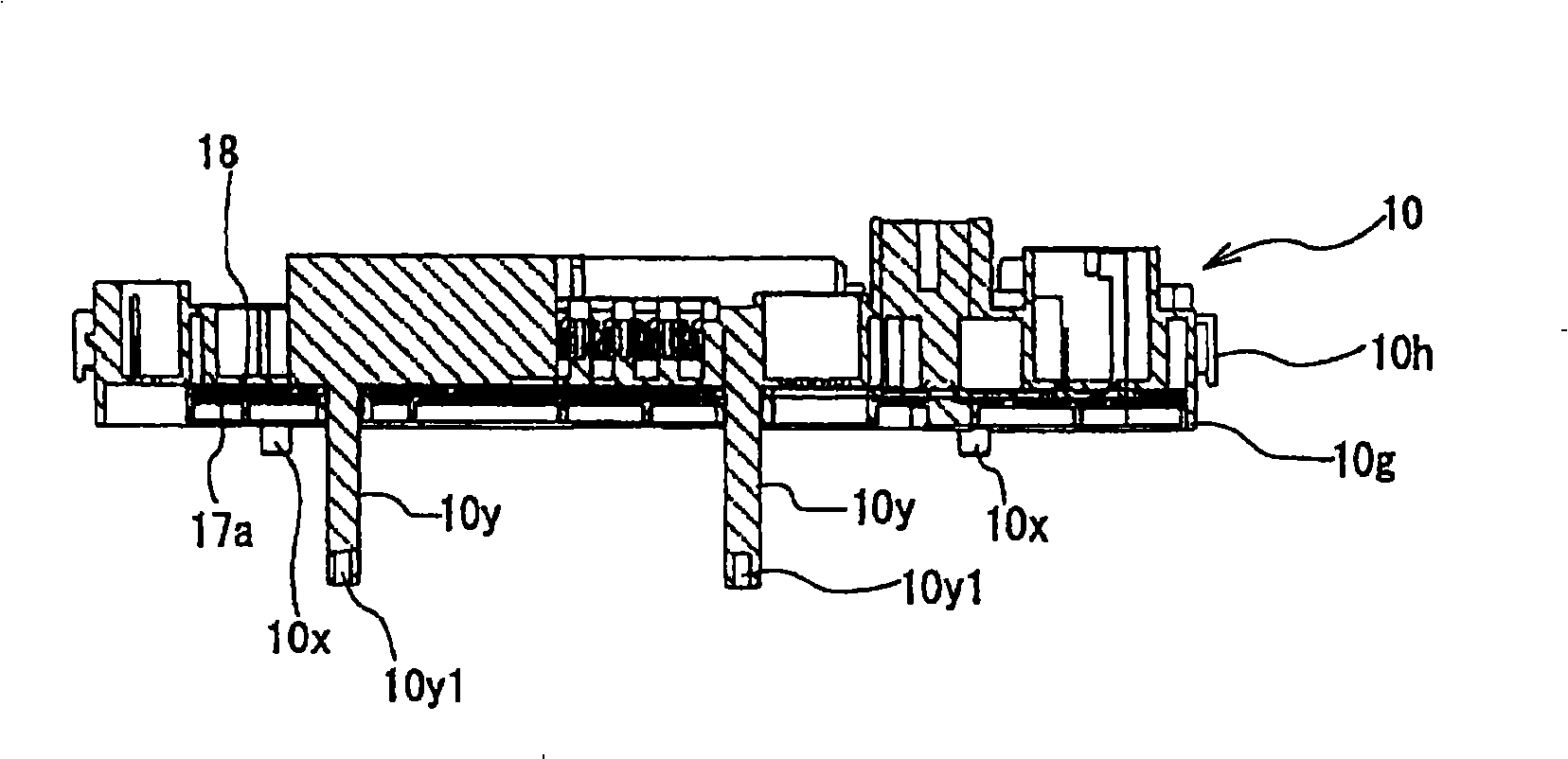

[0036] Such as figure 1 As shown in FIG. 3 , the junction box may include a housing assembly having an upper housing 10 and a lower housing 11 . The bus bar lamination unit 18 and the printed circuit board unit 15 are housed in the case assembly so that they are disposed from the upper case 10 to the lower case 11, and the bus bars 16 and insulating plates 17 are alternately laminated in the bus bar lamination unit, The printed circuit board unit includes a first printed circuit board 13 , a spacer 12 and a second printed circuit board 14 .

[0037] The fixing bar 10x having a shorter size may be integrally formed with the inner surface of the top wall 10a of the upper housing 10, and may extend downward from the inner surface. The shorter fixed rod 10x can penetrate through the busbar lamination un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com