Method for processing step ladder PCB plate

A PCB board and processing method technology, which is applied in the field of stepped PCB board processing, can solve the problems of unevenness, unstable glue flow in the ladder slot, and inability to remove the flow glue to block auxiliary materials, etc., so as to achieve easy removal and stable glue flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

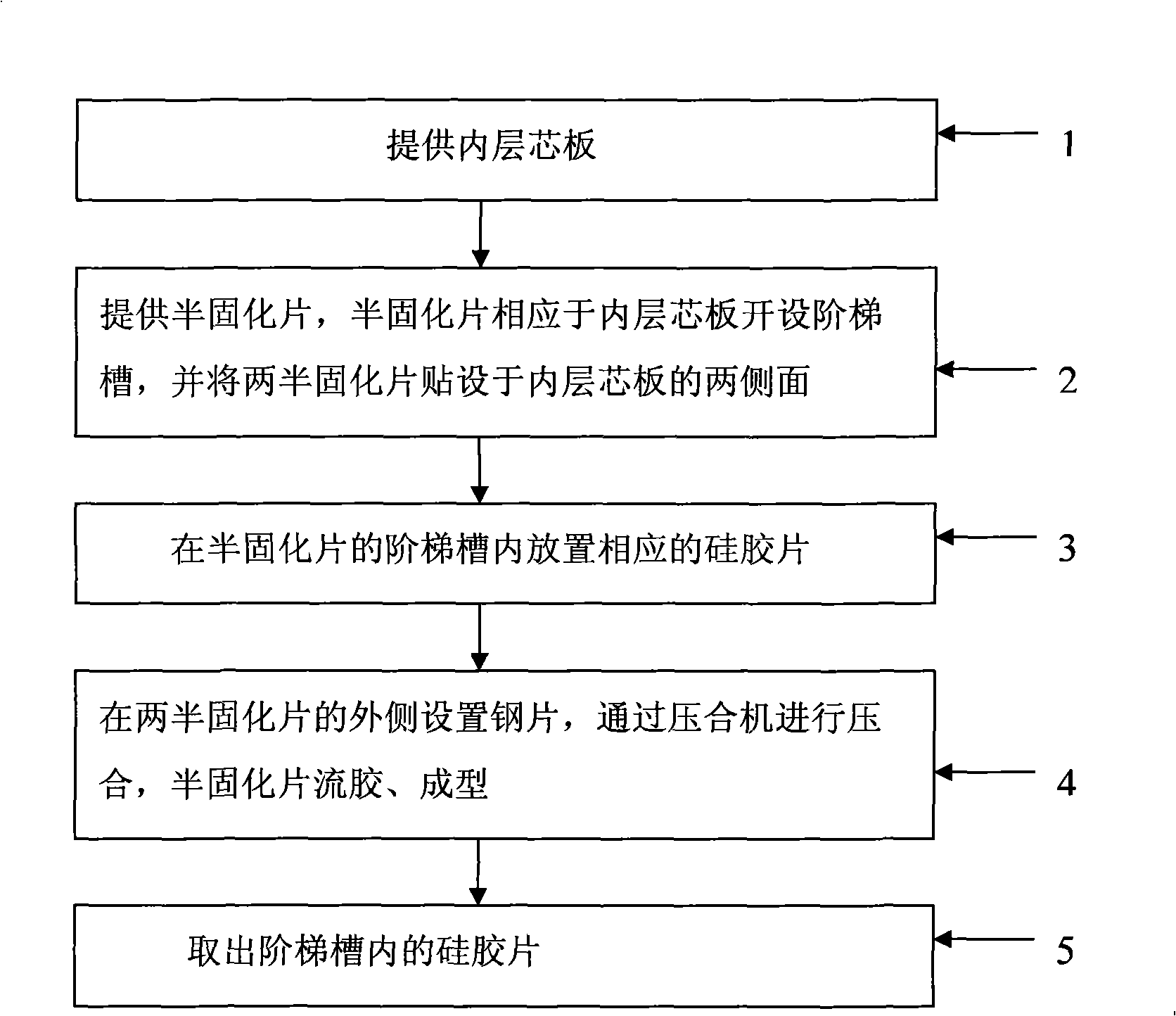

[0018] like Figure 1-2 Shown, the processing method of ladder PCB board of the present invention comprises the following steps:

[0019] Step 1: Provide inner core board; common inner core board can be used.

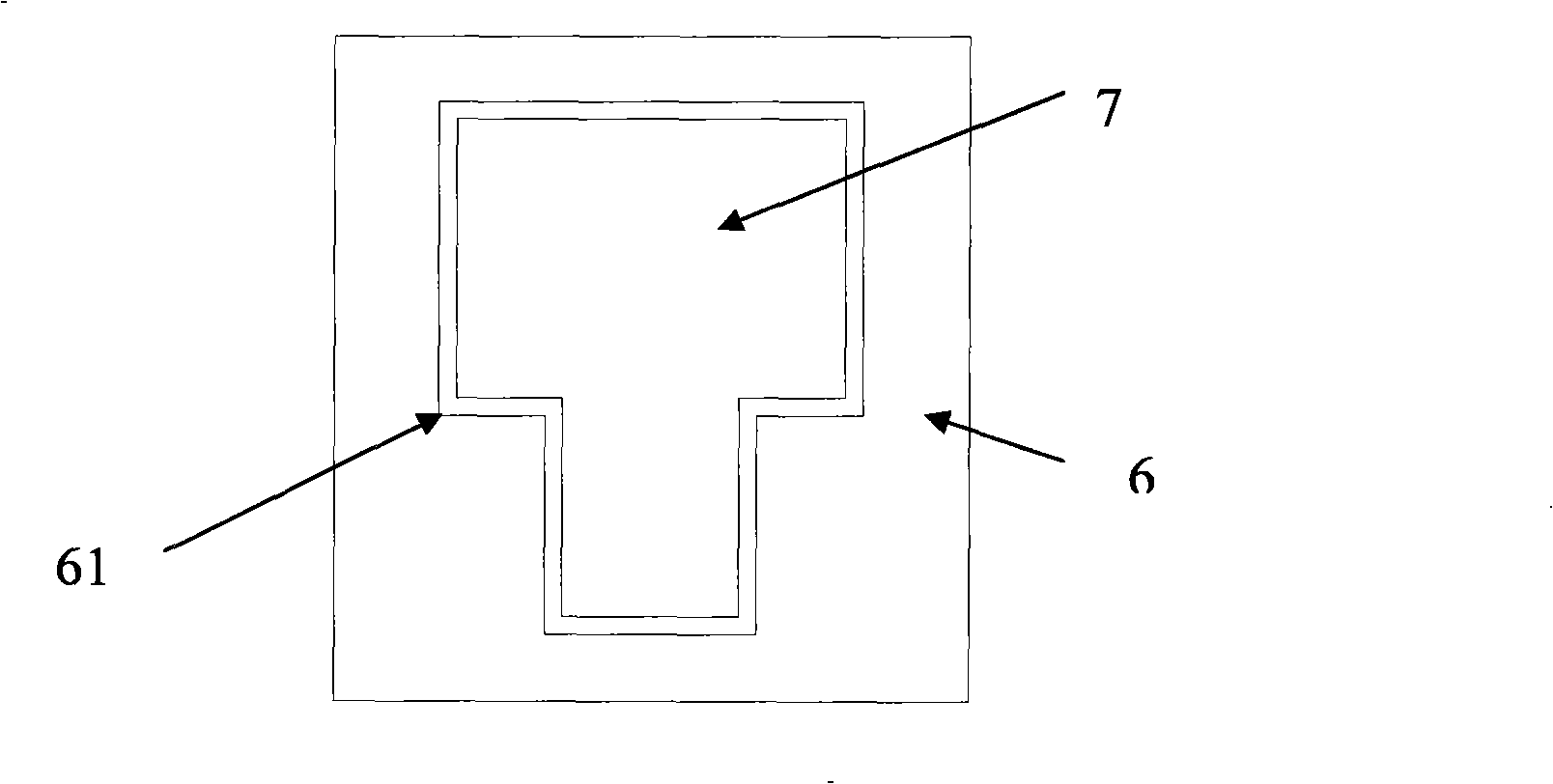

[0020] Step 2: Provide a prepreg. The prepreg is provided with stepped grooves corresponding to the inner core board, and the two prepregs are attached to both sides of the inner core board; refer to figure 2 , in this step, the prepreg 6 is provided with a stepped groove 61 according to the ladder PCB board drawing and suitable pre-compensation, the prepreg is a low fluidity prepreg, and a suitable prepreg is selected to ensure the glue flow at the position of the stepped groove.

[0021] Step 3: Place the corresponding silicone sheet in the stepped groove of the prepreg; refer to figure 2 , in this step, the silica gel sheet 7 is selected according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com