Method and machine for automatically inspecting and sorting objects according to their thickness

A technology of objects and equipment, applied in the field of automatic real-time classification of products, which can solve problems such as long time and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

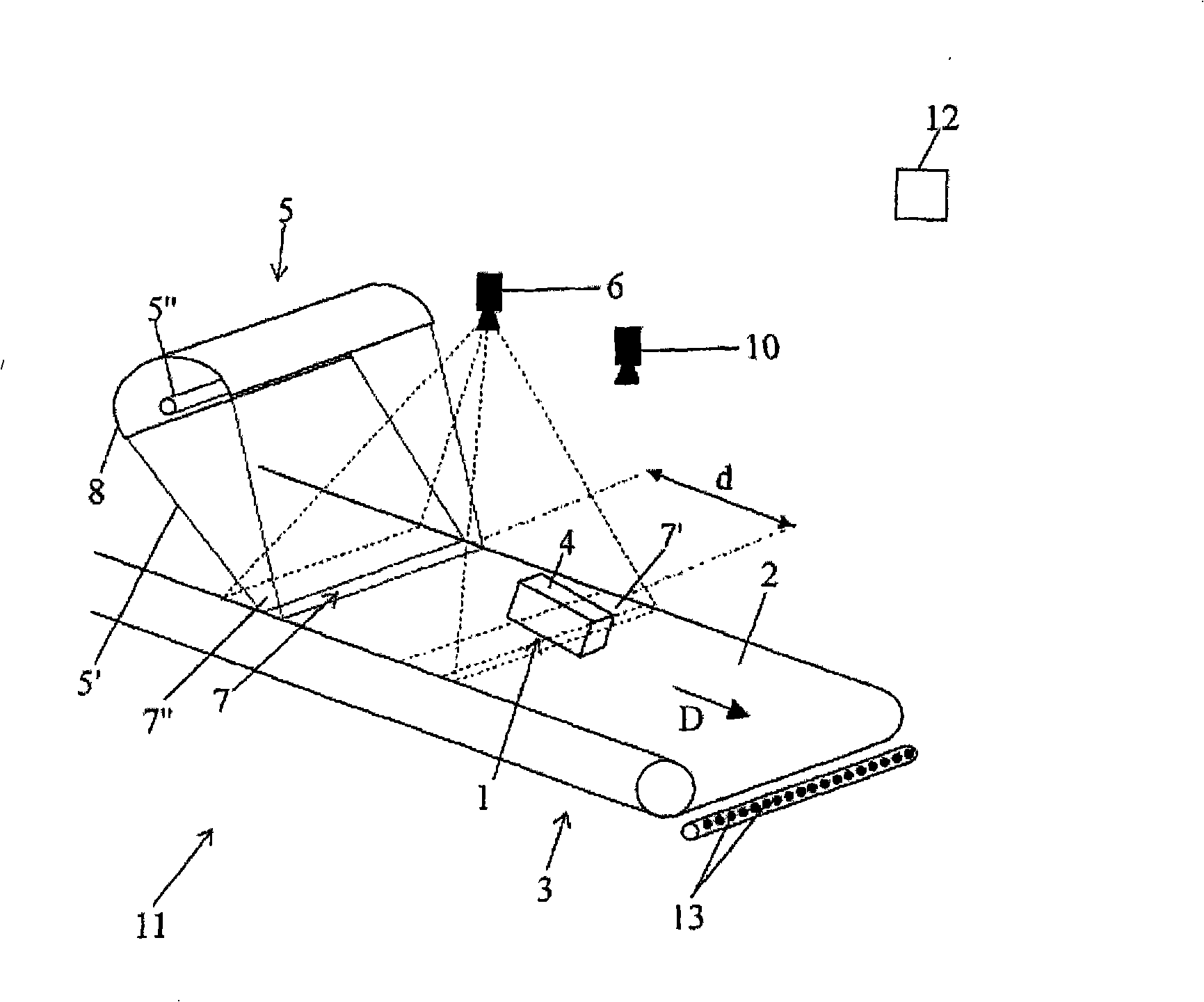

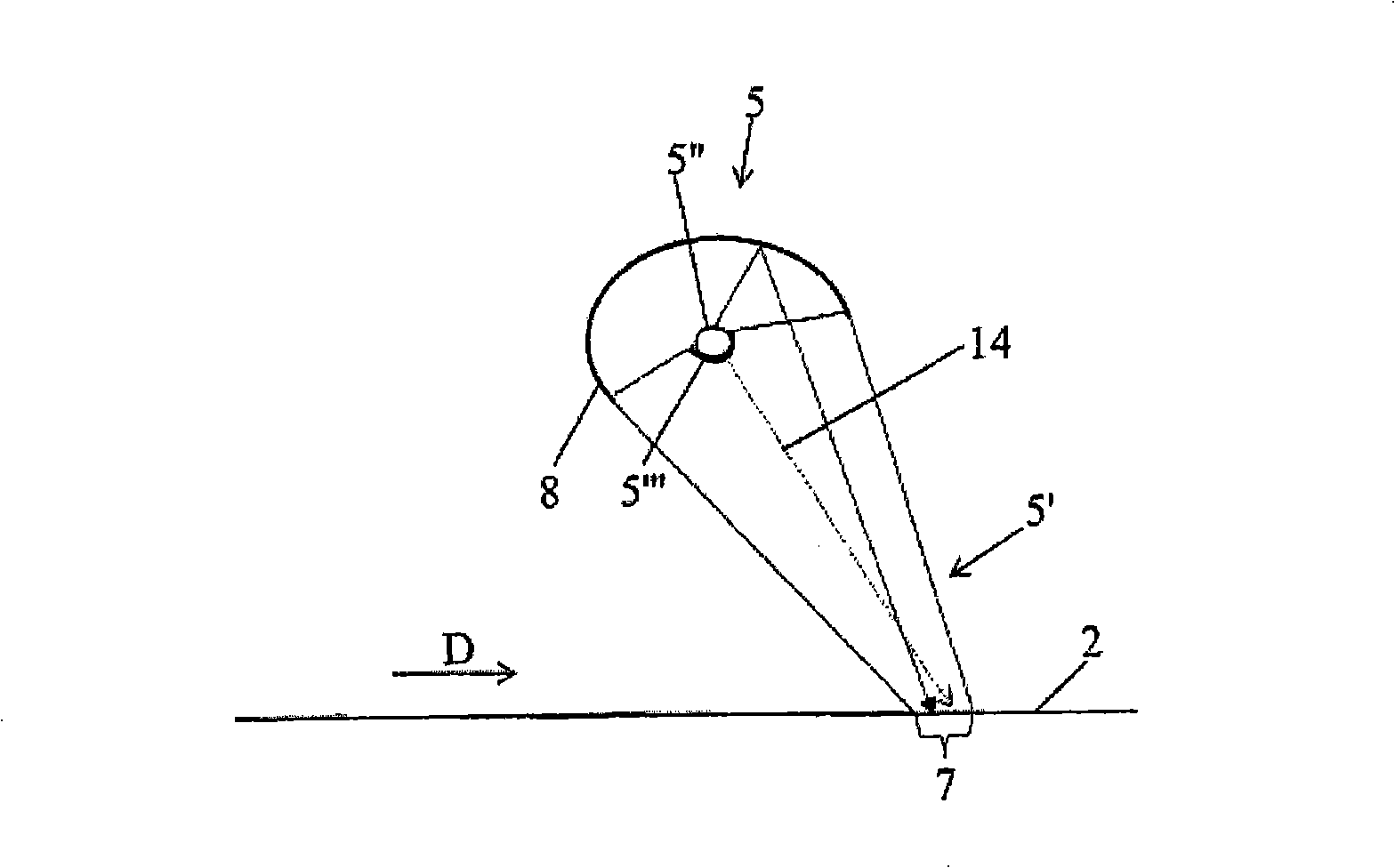

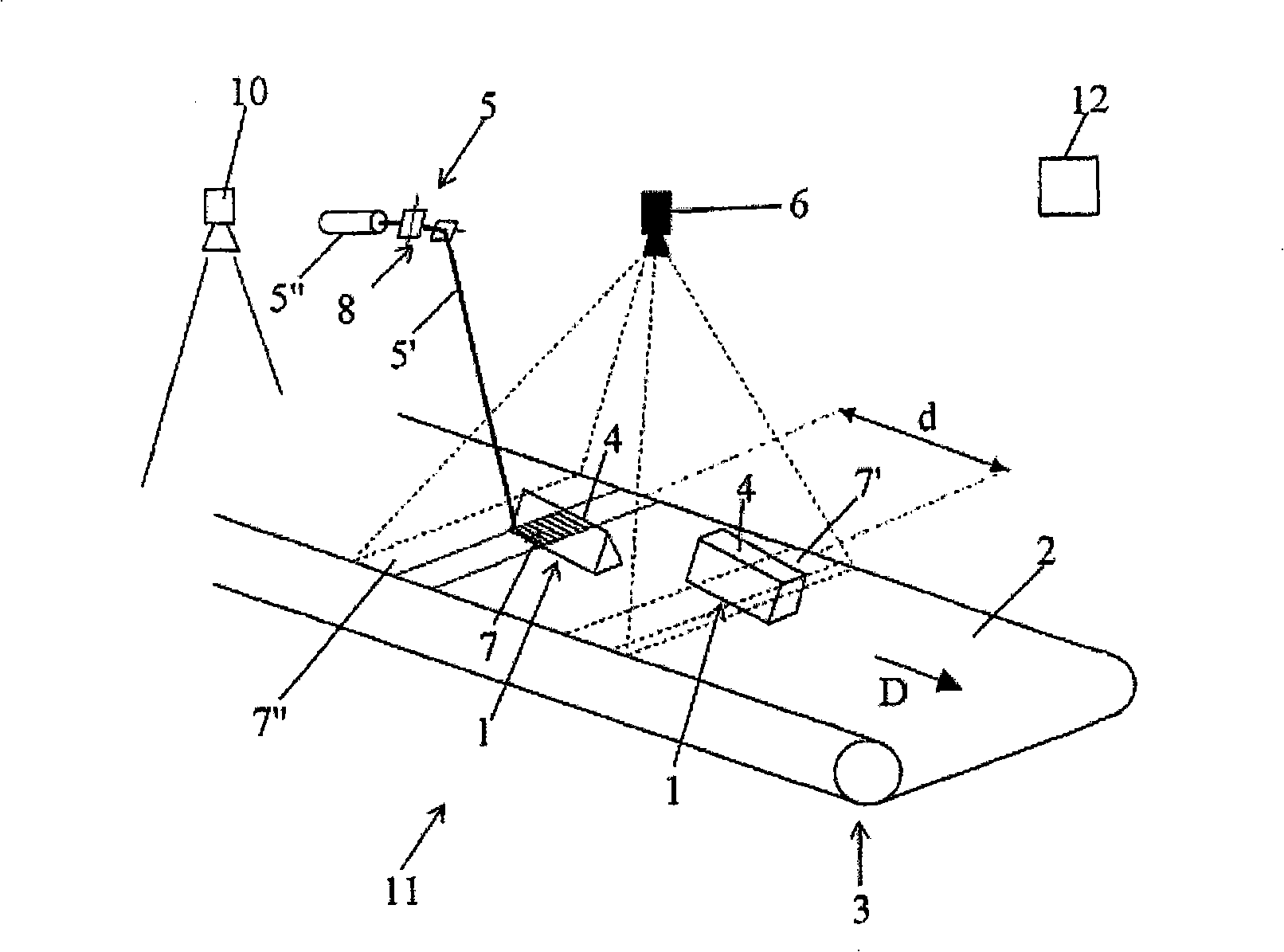

[0038] as in the attached figure 1 with3 As particularly illustrated, the present invention relates to an automatic method for the inspection and classification of non- Metal objects 1 in order to perform at least one type of discrimination or identification at the level of these objects based on at least one compositional or structural feature of these objects.

[0039] More particularly, the method essentially consists in temporarily subjecting a surface or outer layer 4 of said object 1 to the thermal radiation of at least one remote heating device 5, so as to transmit non-alternating heat pulses to these passages. on each of the objects 1, and said heat pulse is identical for all objects in terms of the heat energy applied per unit surface area in the conveying plane 2; Obtain at least one thermal image (thermal image) of each of said objects by a linear or matrix thermal sensor 6 such as a thermal camera; then, according to the data contained in its thermal image, the E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com