Grid tee for suspension ceiling

A technology of grid and ceiling, applied in the field of ceiling system, to achieve the effect of increasing rigidity, increasing torsional rigidity, high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

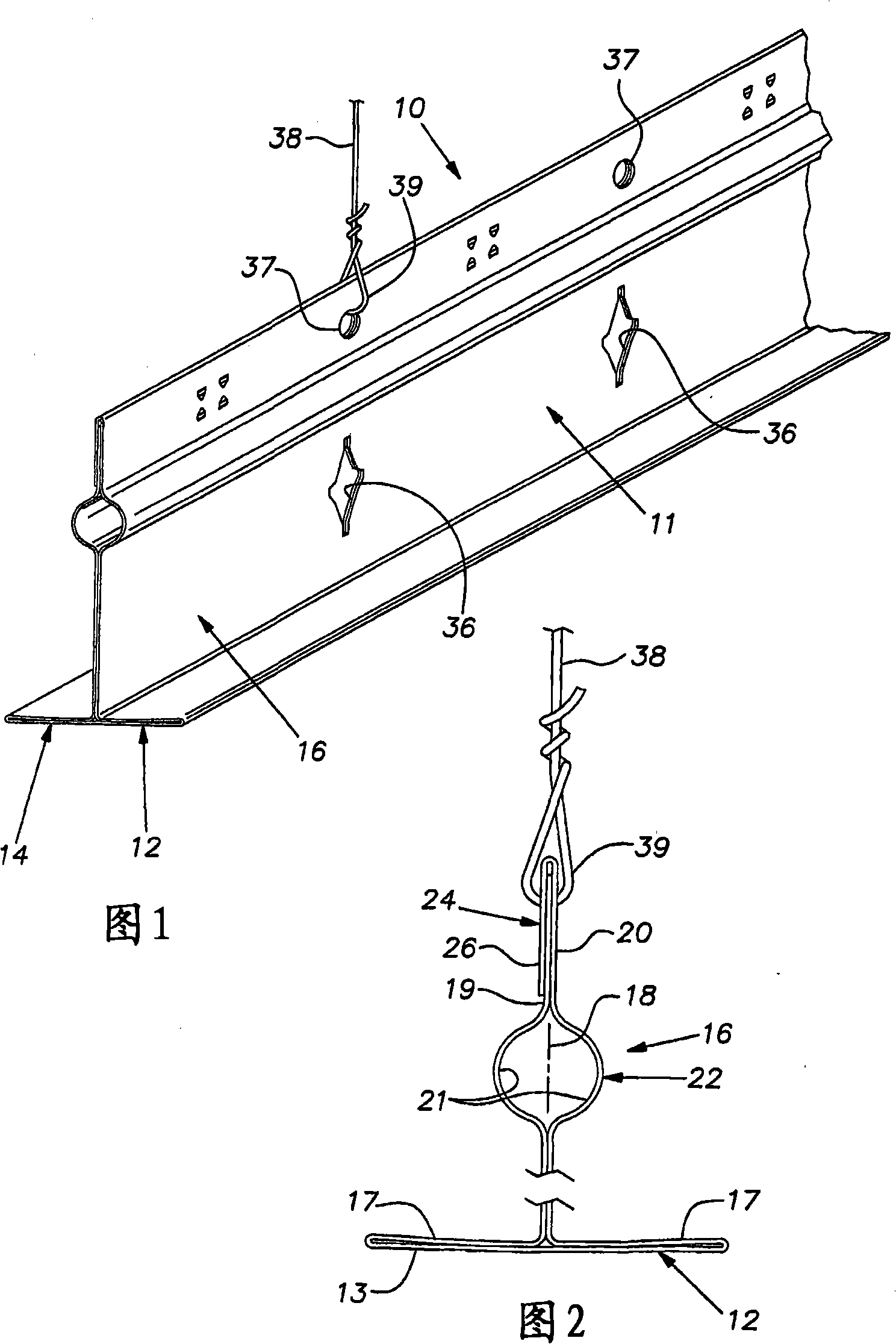

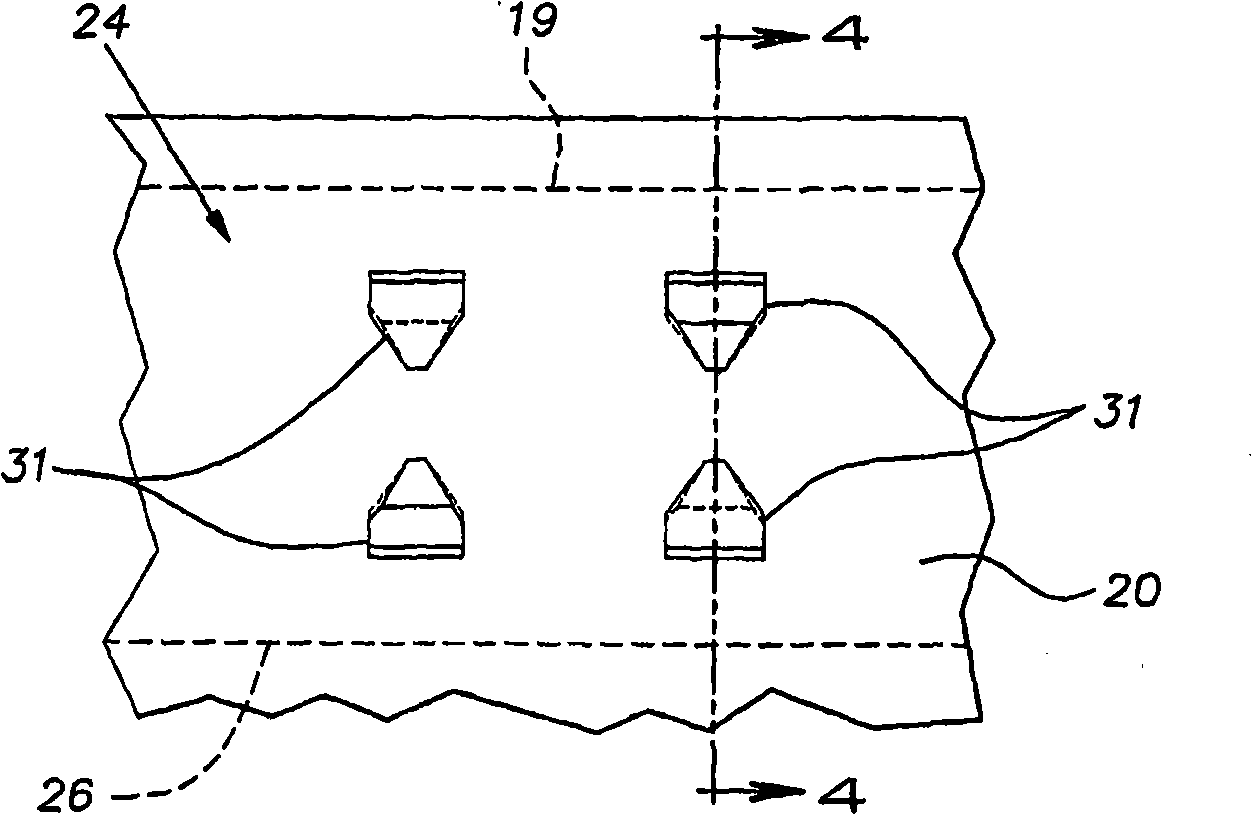

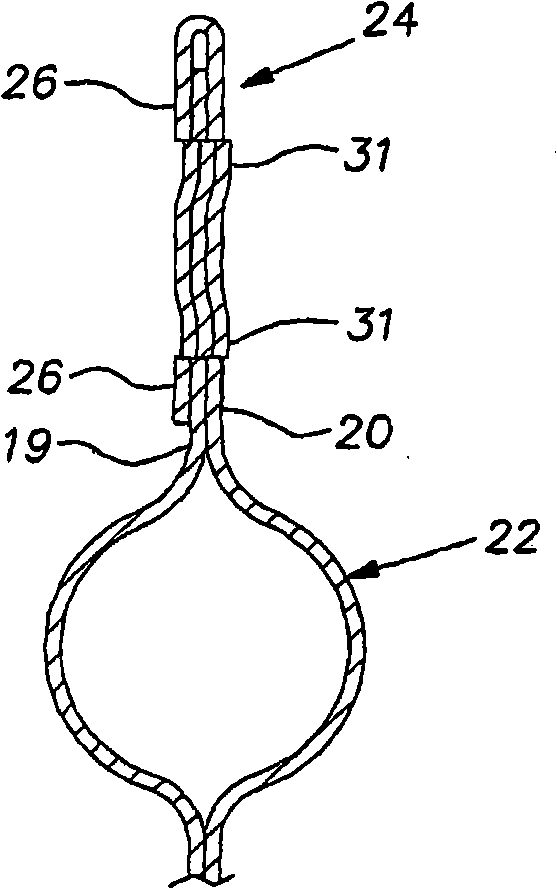

[0017] The grid tee 10 is preferably formed from a sheet of metal strip which may be galvanized or otherwise treated to resist corrosion. Preferably, the T-shaped piece 10 is made to have a cross section such as that shown in FIG. 2 using roll forming techniques known to those skilled in the art. Preferably, the central portion 12 of the metal strip 11 is painted before the metal strip is formed into a T-shaped section. The painted central part 12 forms the visible face 13 . The sheet metal strip 11 is folded back on two opposite sides of the visible face 13 to form a double flange 14 extending laterally on two opposite sides of a central plate or bar 16 . The inner layer 17 of the flange 14 extends from the outer end of the flange to a central imaginary plane 18, and preferably adjoins the outer layer or central portion 12 substantially across its entire width. The inner layers 17 of the flanges 14 meet at an imaginary plane 18 where the sheet metal strip is bent at right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com