Insoles

A technology for insole and auxiliary pad, applied in the field of polyurethane insole, can solve the problems of troublesome production, high cost, many production materials, etc., and achieve the effects of convenient production, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

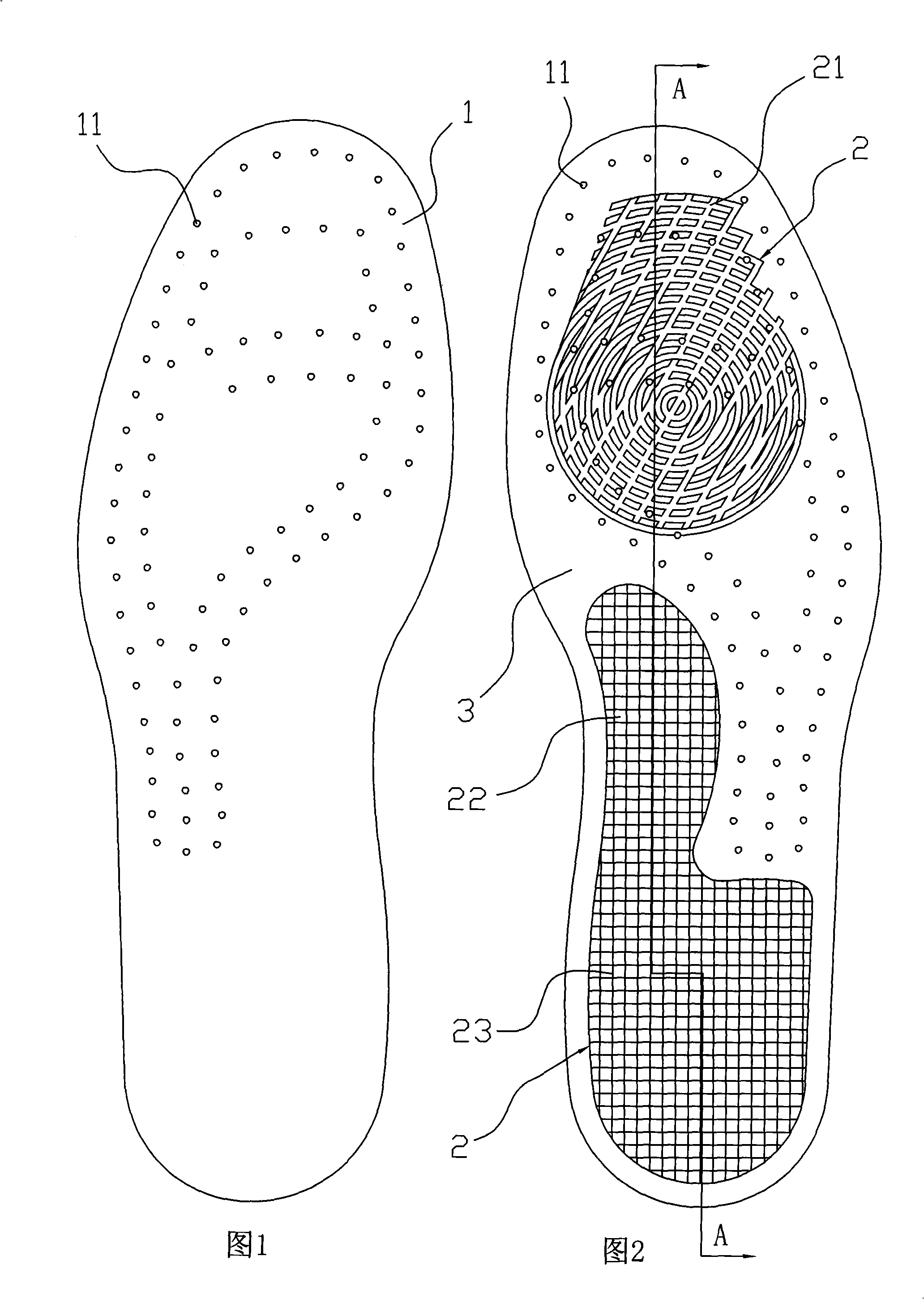

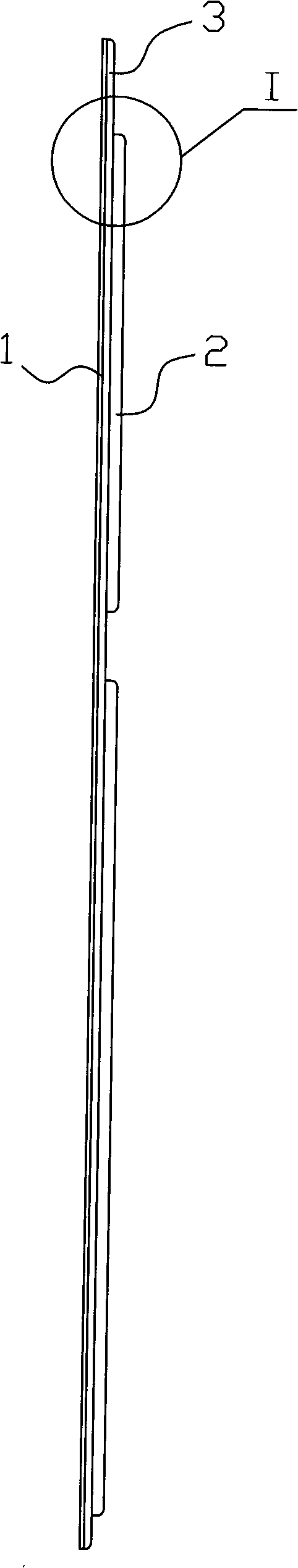

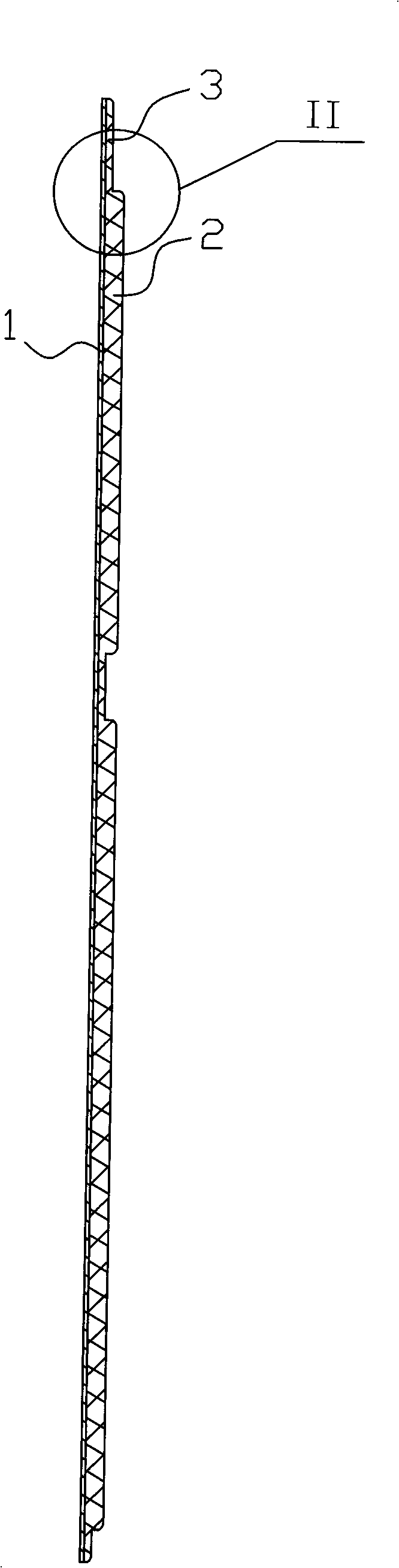

[0017] As shown in Fig. 1 to Fig. 6, the insole of the present embodiment comprises the face cloth 1 of sole shape, is provided with the polyurethane auxiliary cushion layer 3 of the pure polyurethane face that surface does not have film on the bottom surface of face cloth 11, and in On the lower surface of the auxiliary cushion layer 3, a polyurethane cushion layer 2 with a pure polyurethane surface without a film protrudes from the position of the force-bearing part of the heel and the sole of the foot. The surfaces of the auxiliary cushion layer 3 and the soft cushion layer 2 have no film coating, so they have certain viscosity and can be pasted together with the sole. And on the lower surface of the auxiliary cushion layer 3 and positioned at the foot bridge cavity position, the polyurethane foot bridge cushion layer 22 that is integrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com