Chuck type flapwheel

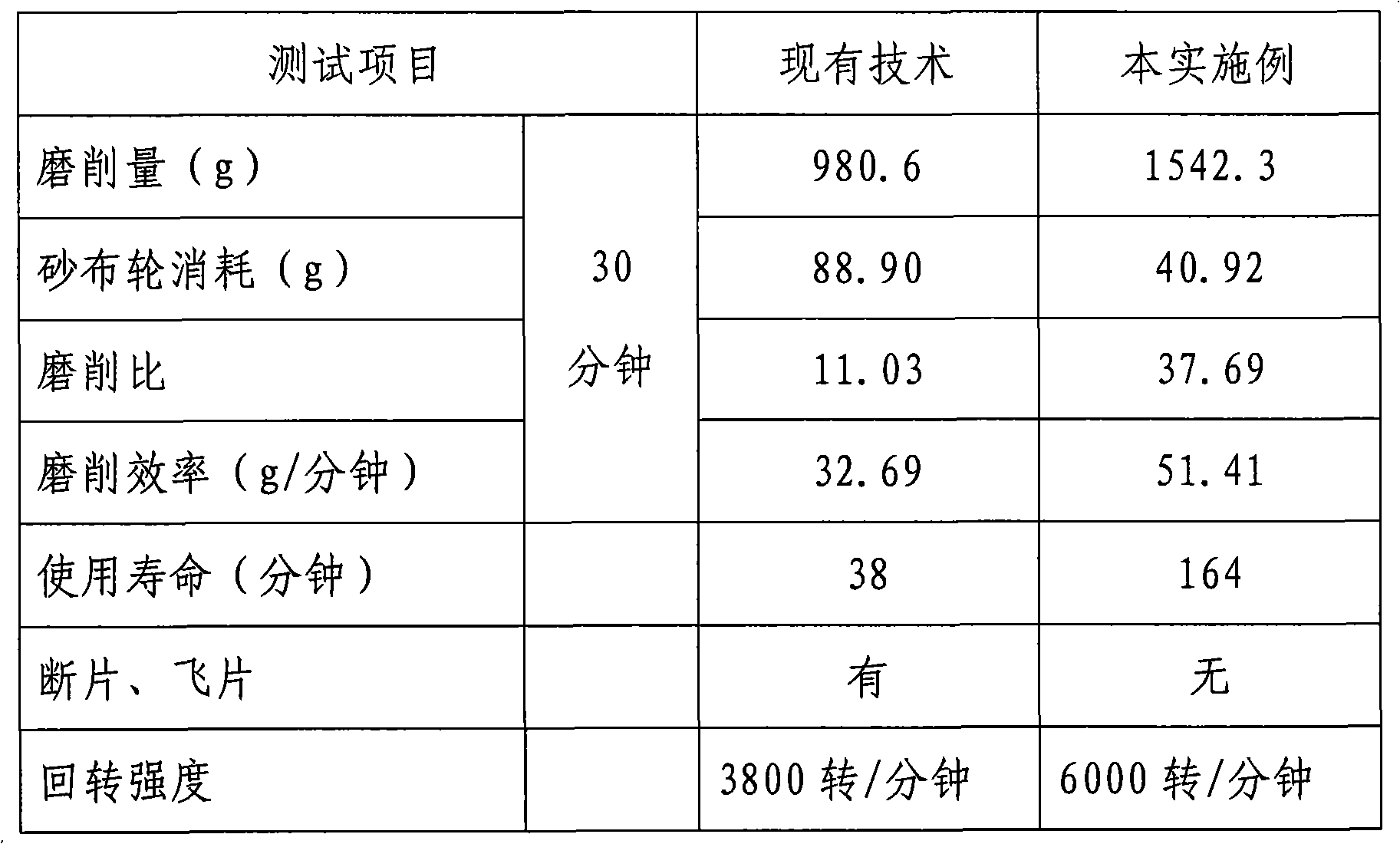

A page wheel and chuck technology, which is applied in the field of chuck page wheels, can solve the problems of short product life, broken pieces, flying pieces, and low grinding efficiency, and achieve the goals of not easy flying pieces, increasing service life, and improving grinding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

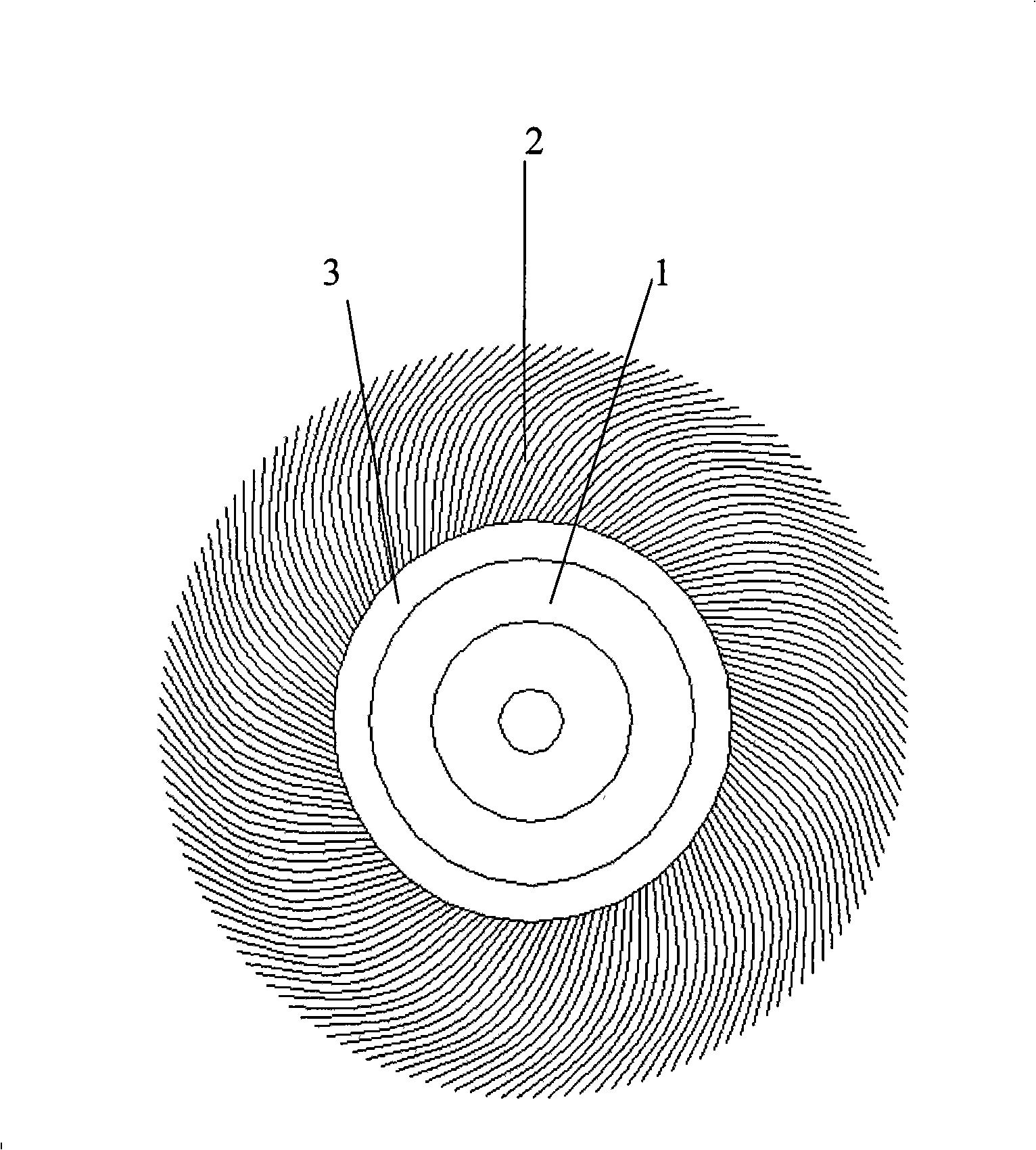

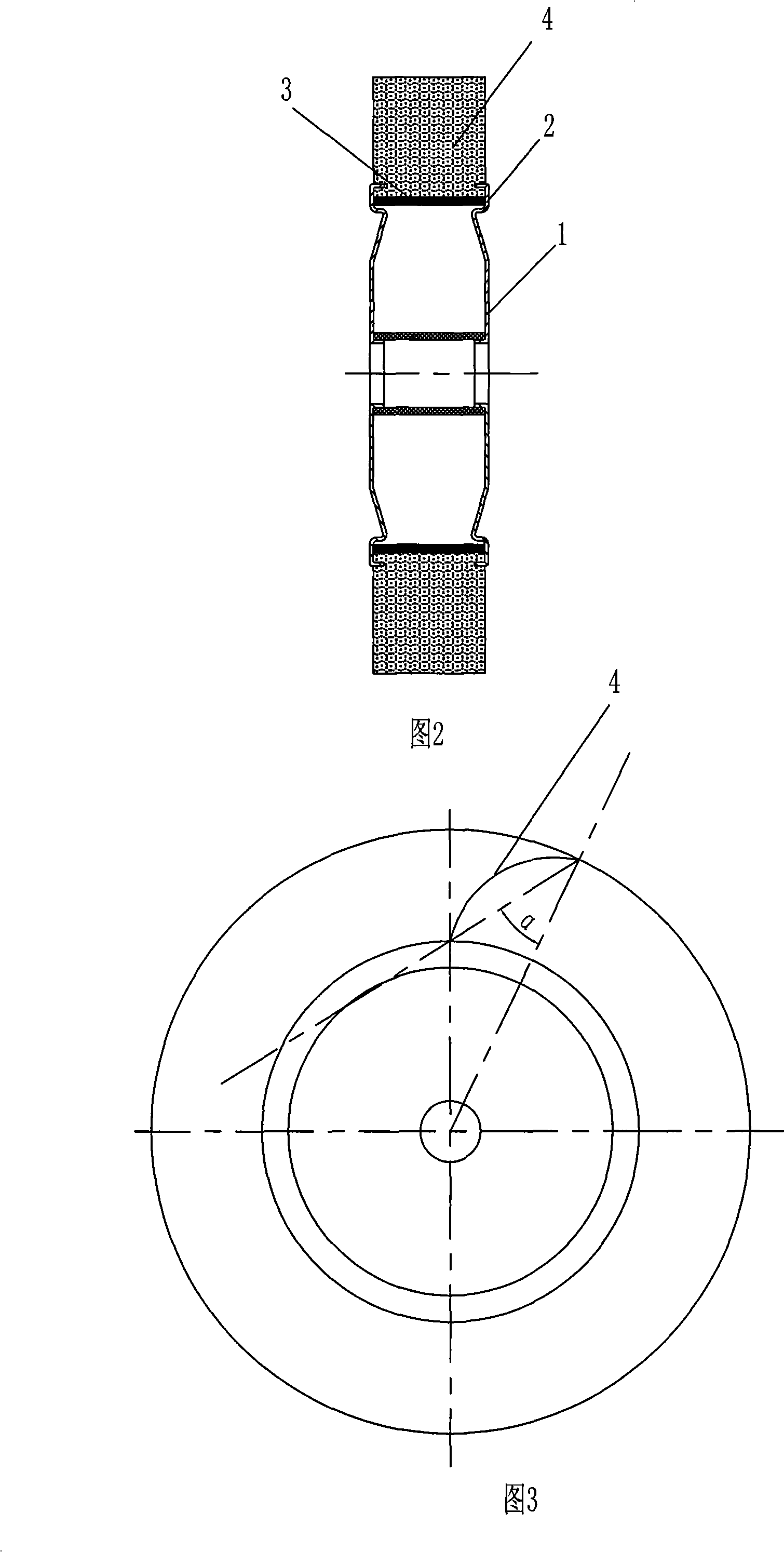

[0011] Examples of the present invention figure 1 , Figure 2 and Figure 3, the outer ring of the end cover 1 is the end cover flange 2, the inner circle 3 is set inside the end cover flange 2, the emery cloth sheet 4 is bonded on the inner circle 3, and the end cover flange 2 The outer feet are embedded in the emery cloth sheet 4 to further limit the emery cloth sheet 4 . One group of abrasive cloth 4 is bonded on inner circle 3 to form a circle. A single emery cloth sheet 4 is arc-shaped, and the arc radians of each emery cloth sheet 4 in a group are the same. The angle α formed by the line connecting the two ends of the single arc-shaped emery cloth sheet 4 with the outermost end point of the sand line sheet 4 and the center of the circle on the end cover 4 is 30 degrees. The outermost end point of a single emery cloth sheet 4 deviates from the line connecting the bonding point and the center of the end cover, and the deviation angles of each emery cloth sheet are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com