Scroll type booster

一种增压装置、涡轮式的技术,应用在用于弹性流体的泵送装置的部件、旋转活塞式泵、液体变容式机械等方向,能够解决使用大型电磁铁、未必现实、涡轮式压缩机构造复杂等问题,达到抑制不稳定情况、顺畅防自转、旋转动作稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

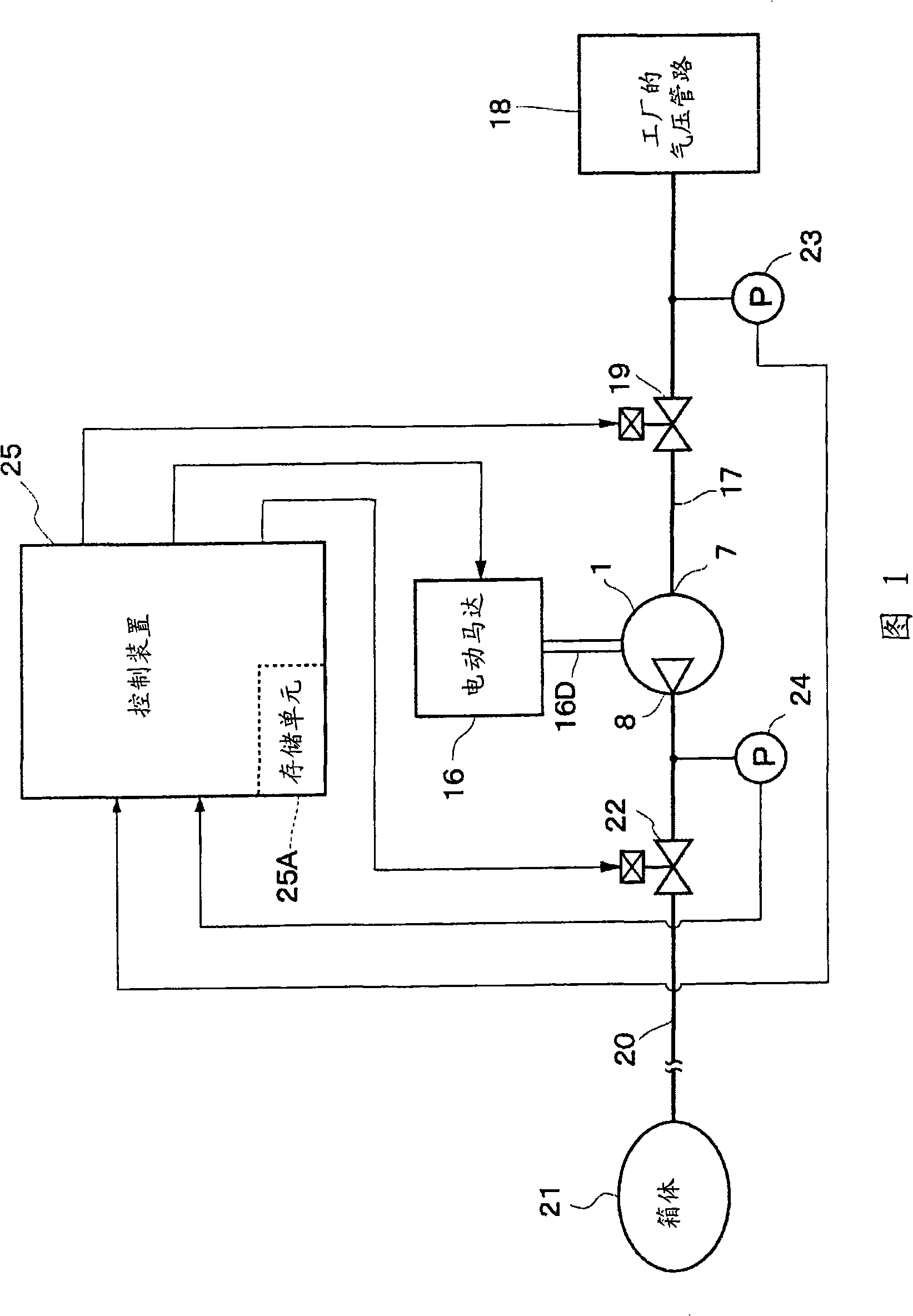

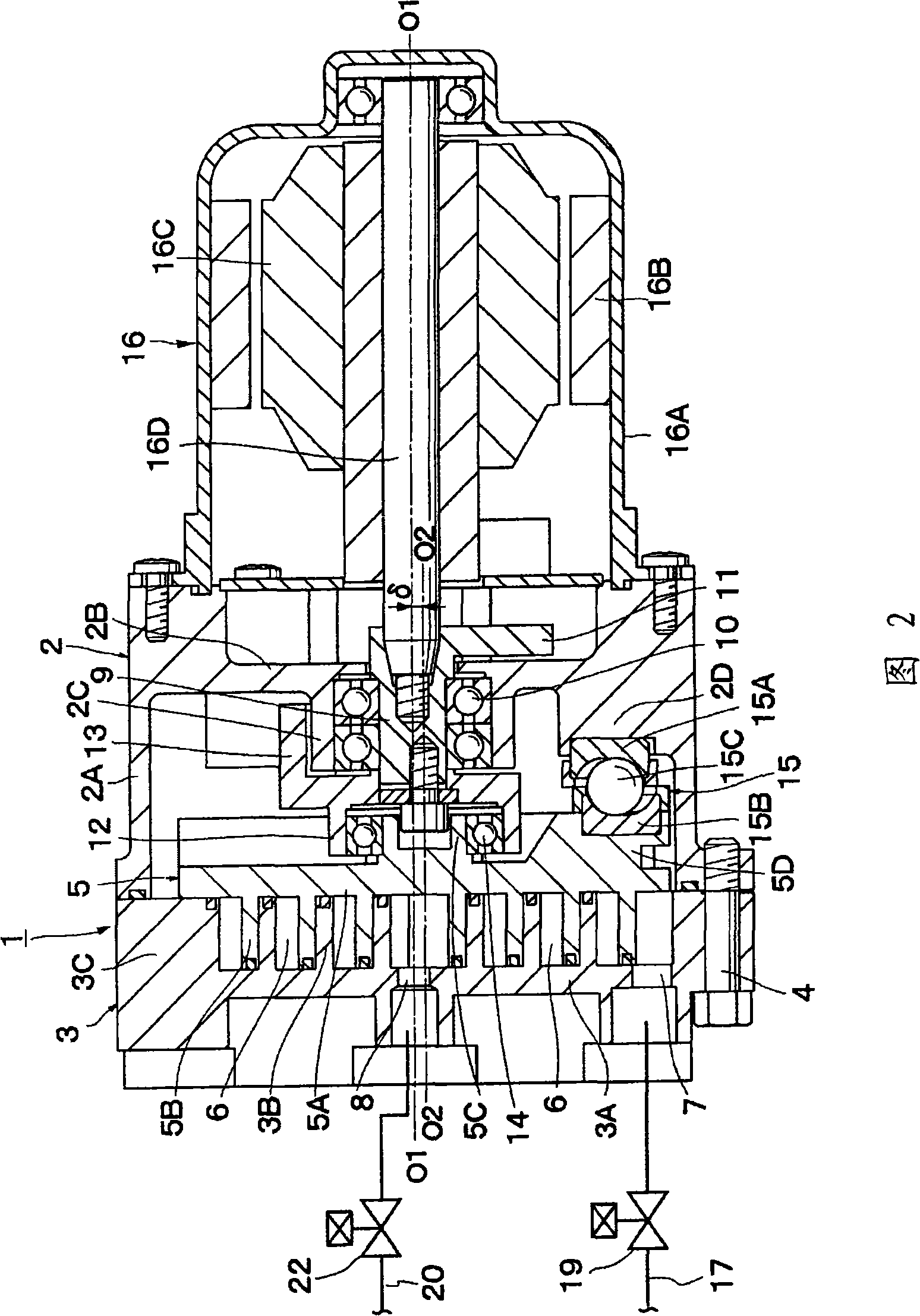

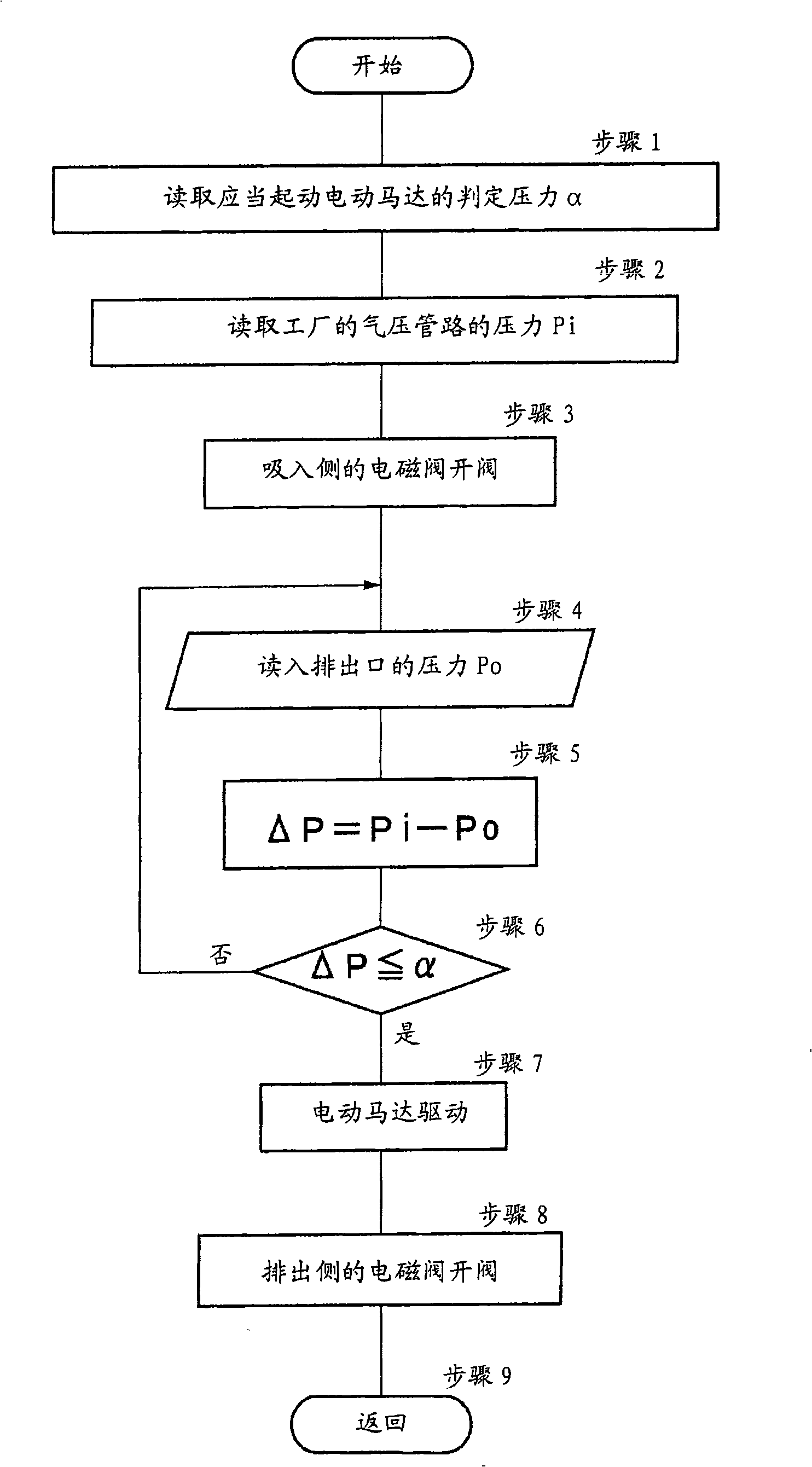

[0051] Hereinafter, the turbocharger according to the embodiment of the present invention will be described in detail with reference to the accompanying drawings as an example when it is used as a supercharger (booster) in a pneumatic pipeline of a factory.

[0052] Here, Figure 1 to image 3 The first embodiment of the present invention is shown. In the figure, 1 is a turbo type compressor main body (hereinafter referred to as compressor main body) constituting a turbo type compression mechanism, and 2 is a cover constituting an outer casing of the compressor main body 1. As shown in FIG. 2 , the cover body 2 is Formed as a bottomed cylindrical body that opens on one side in the axial direction. Further, on the other side in the axial direction of the cover body 2, an electric motor 16 having a drive shaft 16D described later is detachably attached on the axis line O1-O1.

[0053] At this time, the cover body 2 is generally formed to have: a cylindrical portion 2A opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com