Method for correcting dilatometer measuring value

A calibration method and technology of measured values, applied in the direction of thermal expansion coefficient of materials, instruments, special data processing applications, etc., to ensure the accuracy and improve the sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

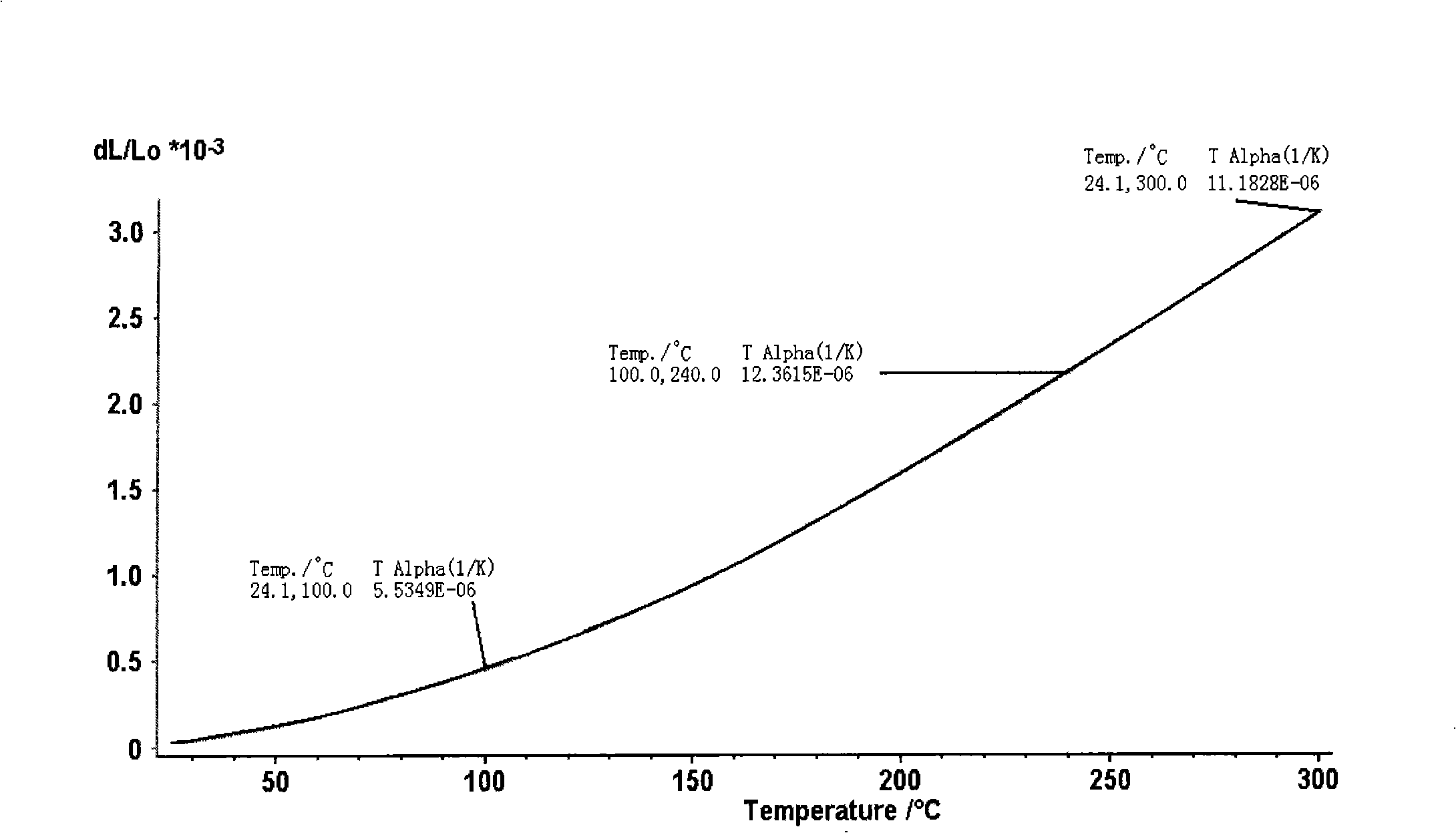

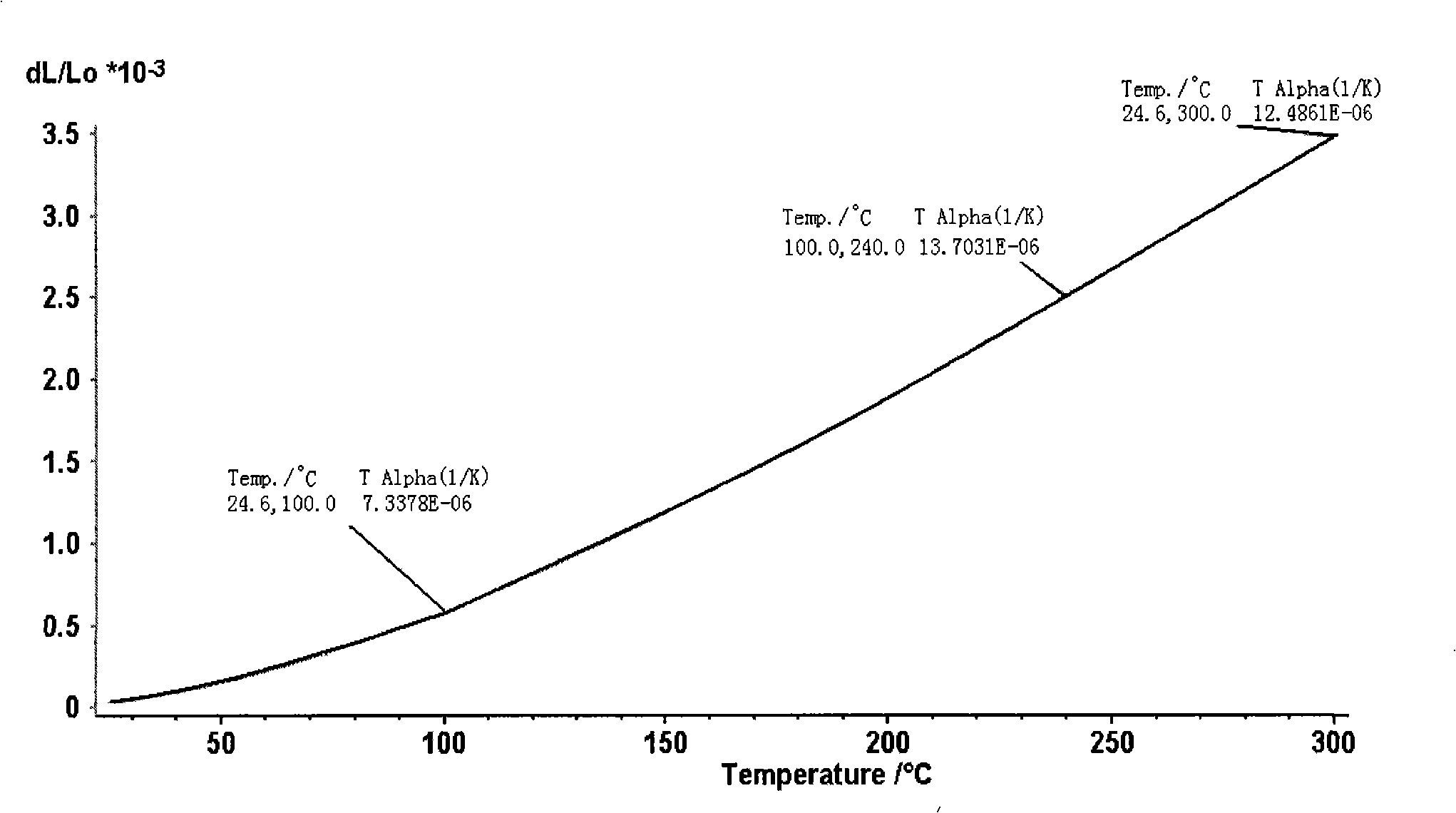

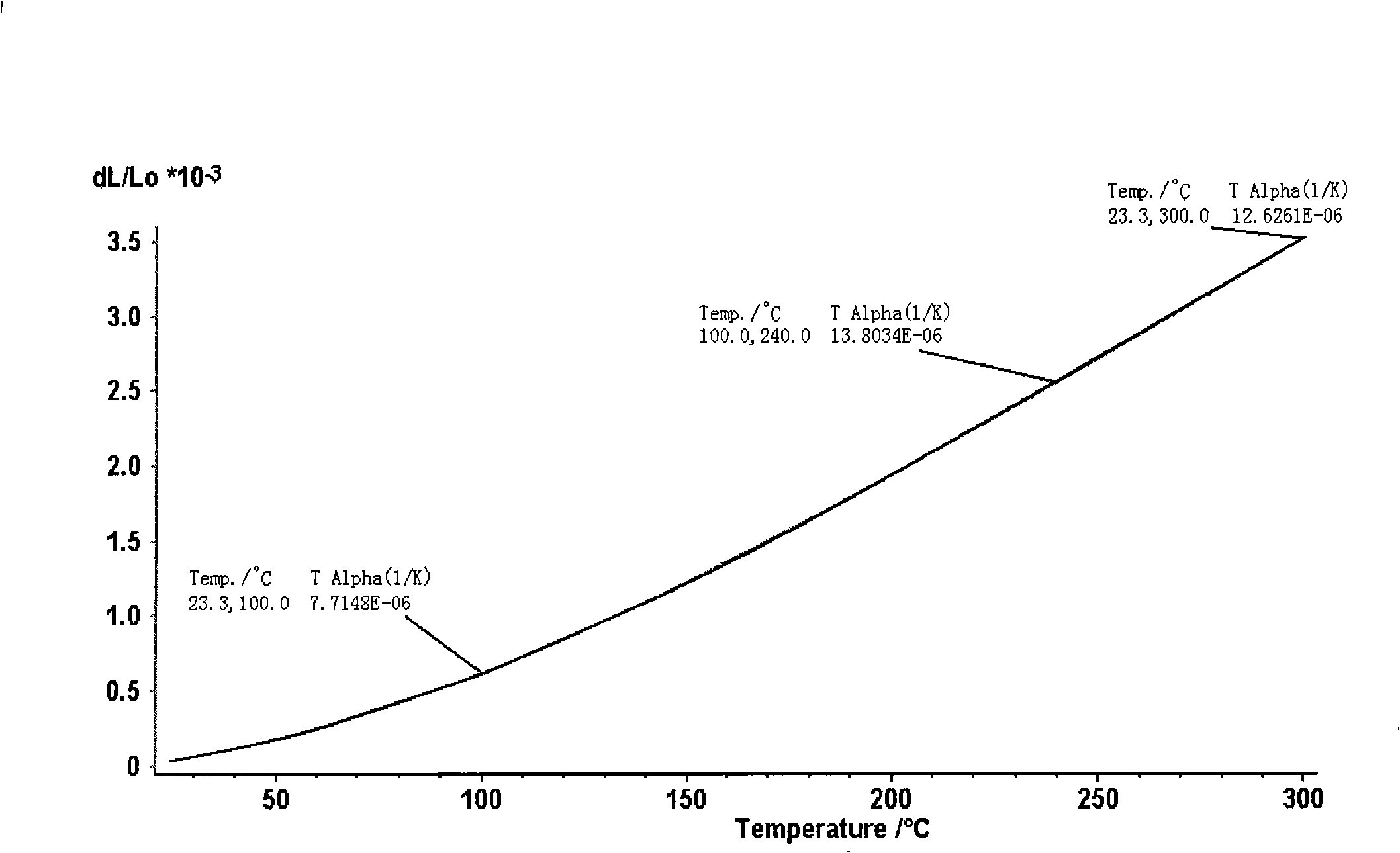

[0030] On the program-controlled dilatometer, the specific implementation process of the present invention is as follows:

[0031] (A) Based on the characteristics and testing requirements of the tested sample, select the standard sample and establish a calibration file corresponding to the above requirements.

[0032] 1. Establish a standard sample measurement state;

[0033] 2. Set the standard sample measurement mode: calibration

[0034] 3. Enter the length of the standard sample: 25mm;

[0035] 4. Input the pressure loaded on the standard sample: 25 ~ 35cN;

[0036] 5. Select the bracket material for standard sample measurement: quartz;

[0037] 6. Select the material of the standard sample: aluminum oxide;

[0038] 7. Set the initial temperature: 20°C;

[0039] 8. Set the final temperature: 800°C;

[0040] 9. Set the safety protection temperature: 810°C;

[0041] 10. Set the heating rate: 5°C / min;

[0042] 11. Set the heating mode: use the furnace to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com