Device for measuring the tension in a metallic strip

A metal belt and tension technology, which is applied in the field of devices with tension, can solve the problems of interfering with the measuring device and the inability of the table to obtain strength, and achieve the effect of high resistance to bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

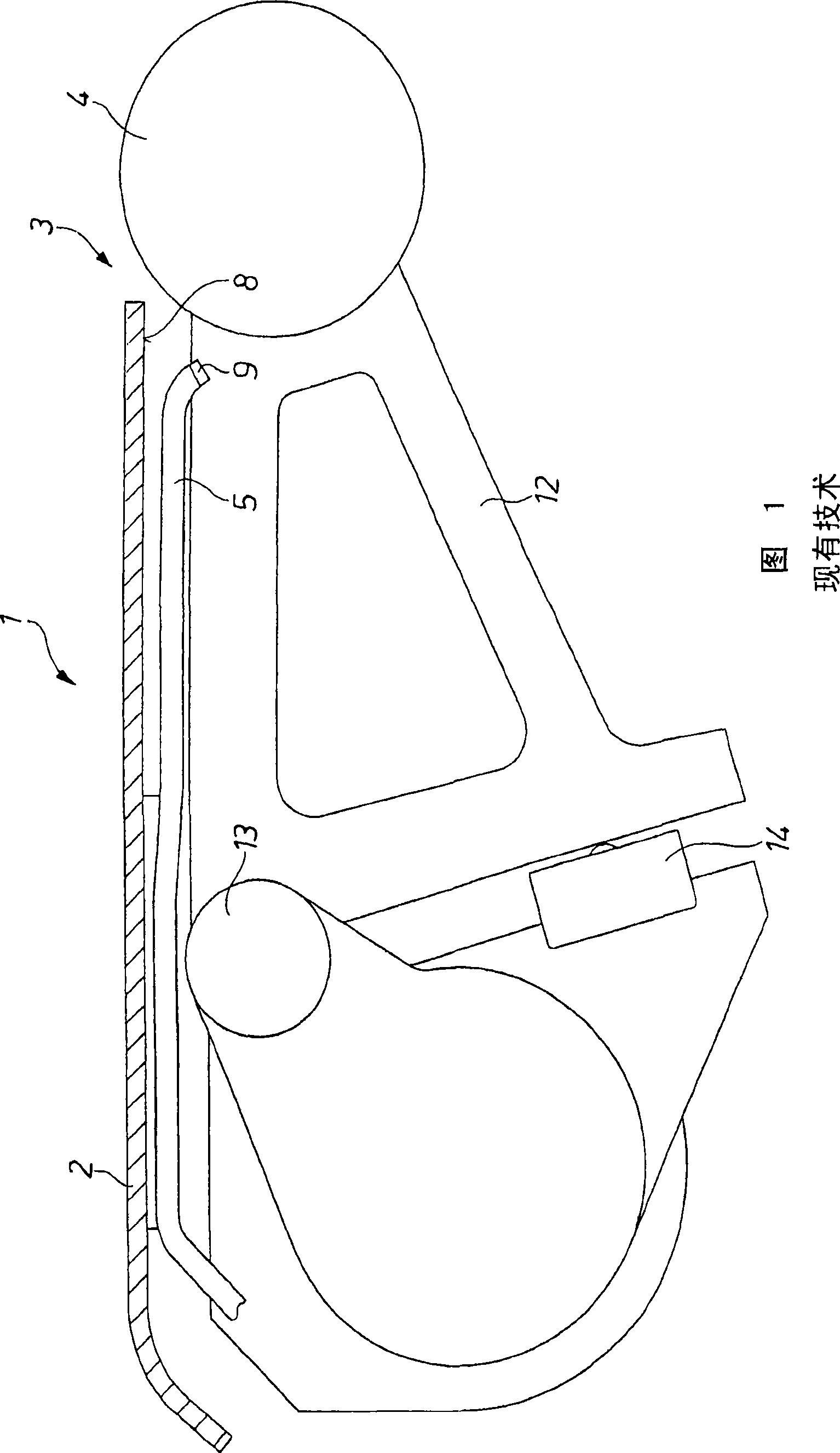

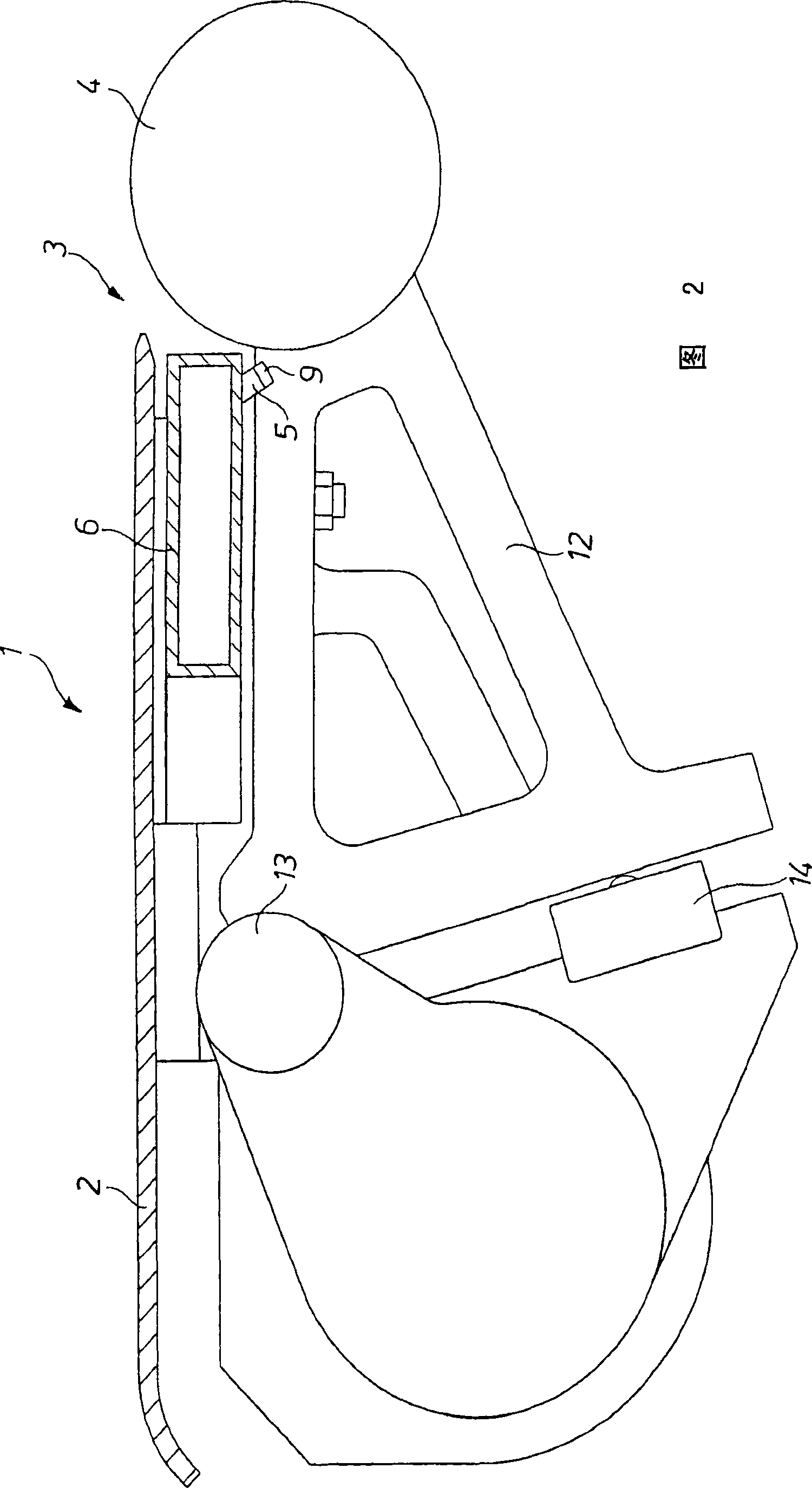

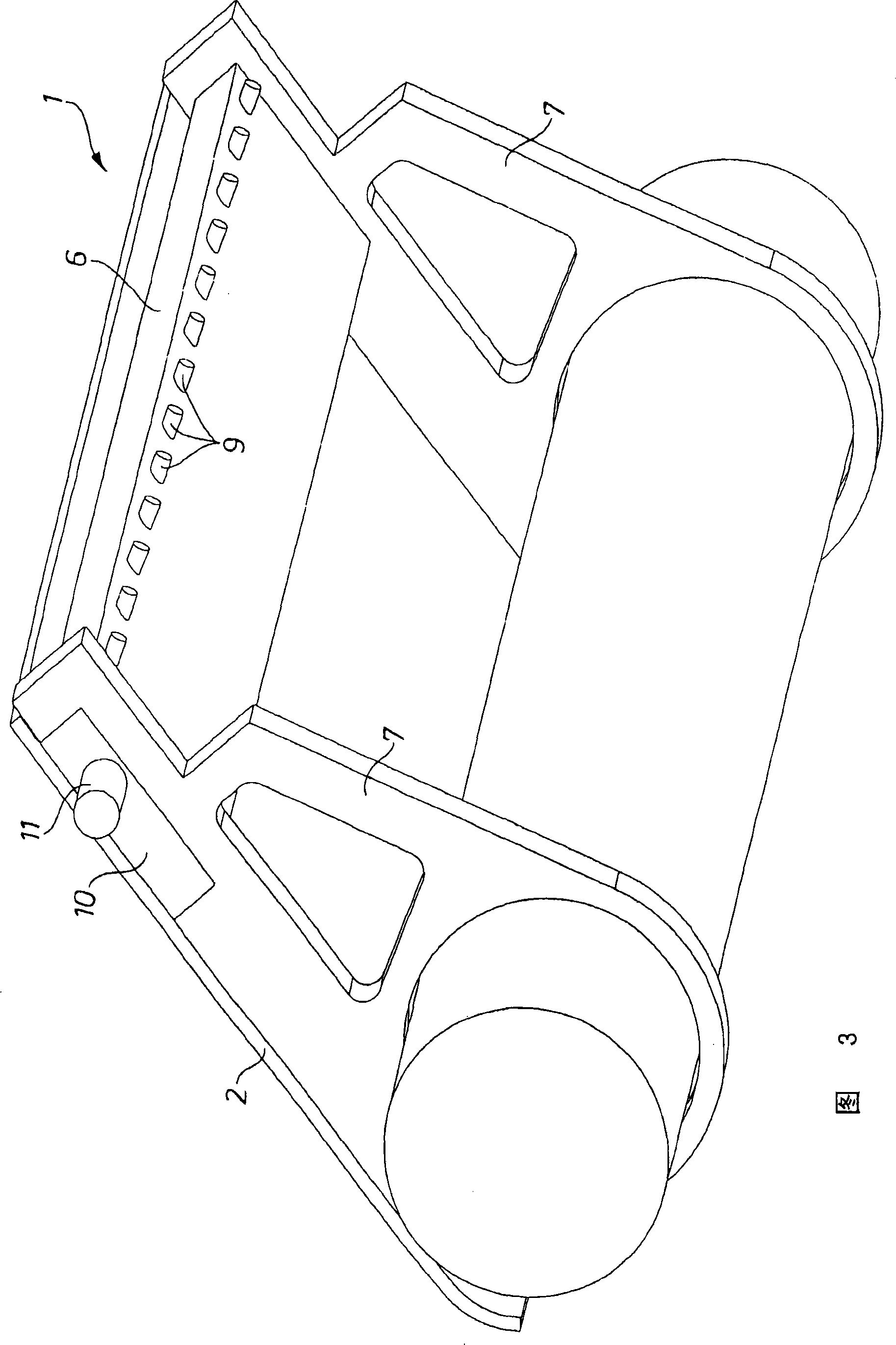

[0020] A device 1 for measuring the strip tension of a steel strip can be seen in the drawings, the steel strip itself not being shown. In its conveying direction, the steel strip passes over a table 2 which forms a flat surface against which the steel strip rests. Measuring elements in the form of measuring rollers 4 are arranged on the front edge 3 of the table. The measuring rollers are each arranged at the end of a support arm 12 , wherein the support arm 12 is mounted in a bearing carrier 13 . One end of the support arm 12 presses against the measuring box 14, so that it can be determined how far the measuring roller 4 is pressed down due to the tension in the steel strip. This provides the possibility to measure the web tension via the measuring elements 4 , 12 , 14 .

[0021] Since the passing steel strip is hot, the measuring roller 4 must be cooled sufficiently for this purpose. For this purpose, a cooling element 5 is provided which extends from a cooling water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com