Numerical control system and method of automatic feed device of titanium electrode product of hydraulic press

A technology of automatic feeding and numerical control system, applied in the direction of feeding device, digital control, electrical program control, etc., can solve the problem that the speed or accuracy of feeding is difficult to adapt to production needs, and the function is single, and achieve the feeding work. Simple, solve the phenomenon of stacking, and optimize the effect of feeding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and the numerical control system and control method of the titanium electrode product automatic feeding device of the hydraulic press of the present invention are described in detail with the accompanying drawings as follows:

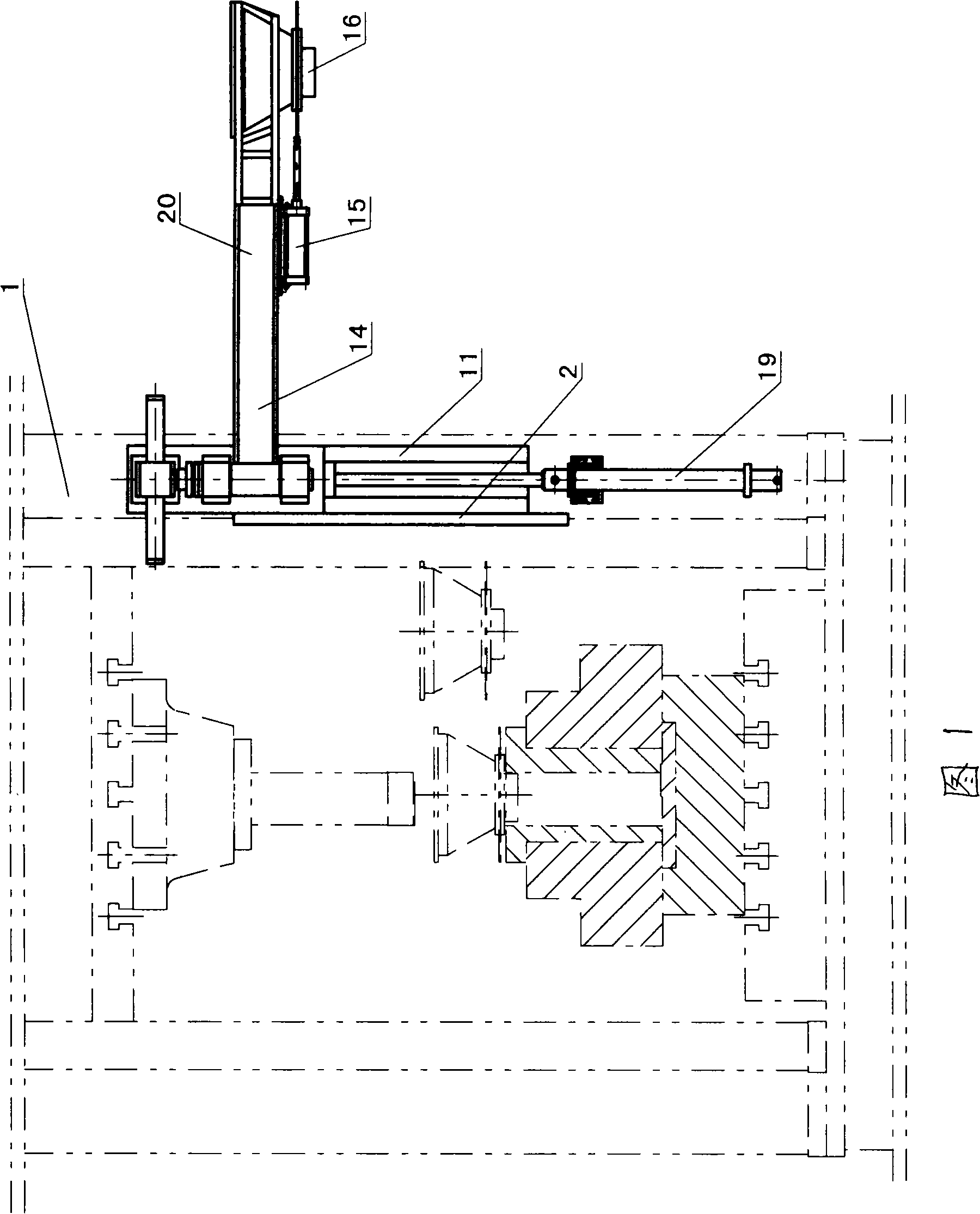

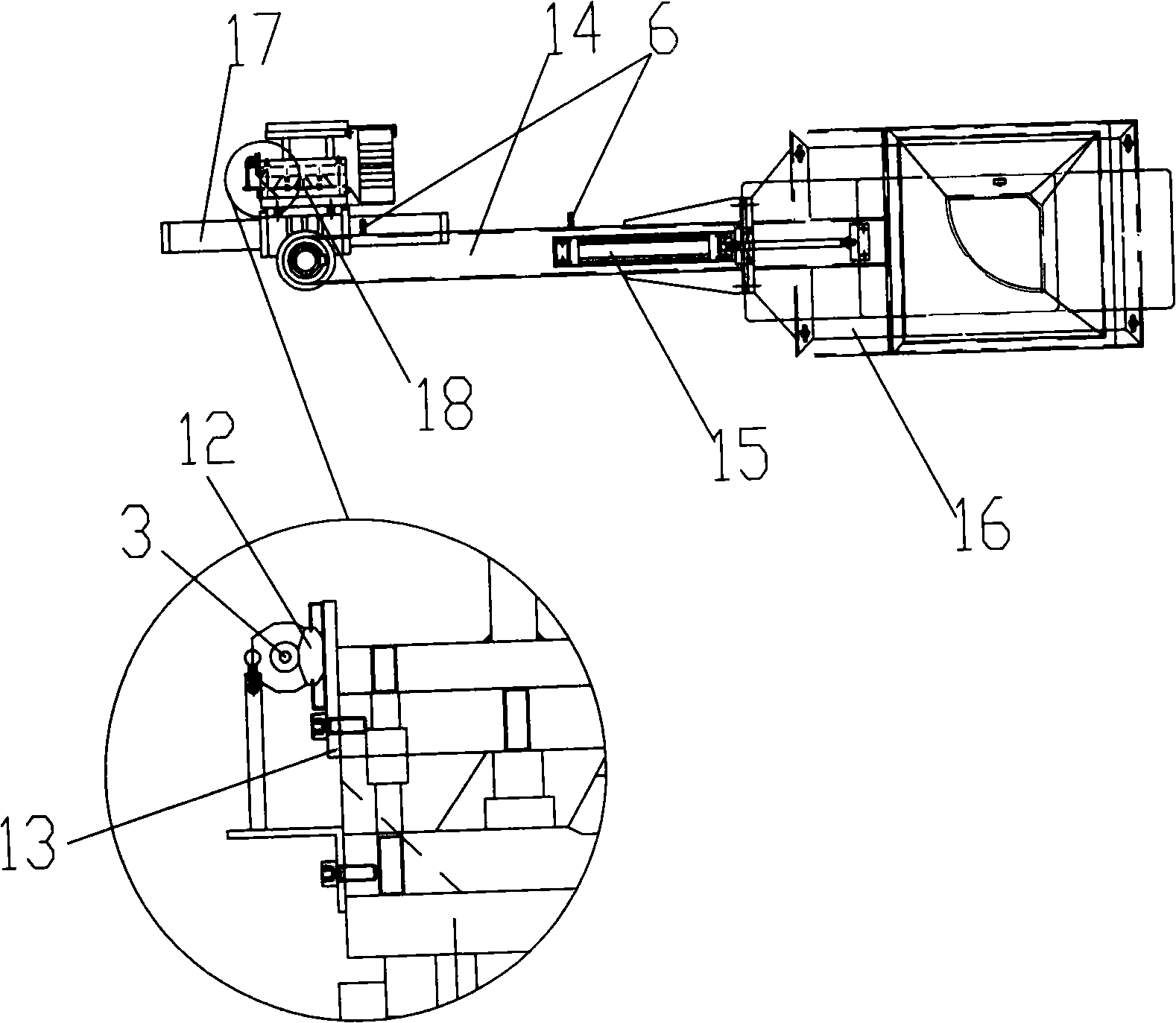

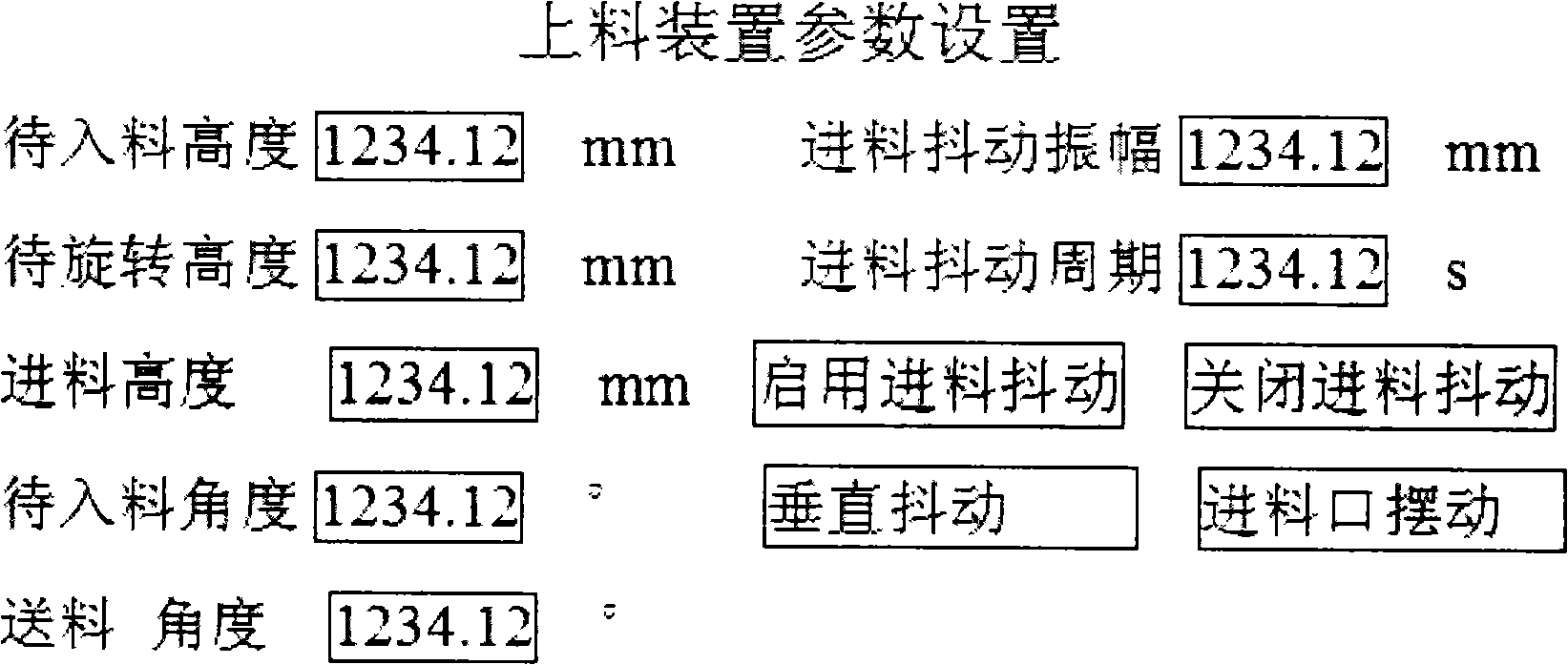

[0031] Figure 1, figure 2 As shown, the numerical control system of the automatic feeding device for titanium electrode products of the hydraulic press includes an automatic lifting and rotating feeding device 20 arranged on the side of the hydraulic press 1; connected with the automatic lifting and rotating feeding device 20 for driving the lifting, The lowering lifting and pushing cylinder 19 is connected to the automatic lifting and rotating feeding device 20 for driving the hopper gate pushing cylinder 15 for feeding and discharging, and is connected to the automatic lifting and rotating feeding device 20 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com