Multi hand writing invoice continuous rotary printing method

A rotary printing and invoice technology, applied to rotary printing machines, lithographic rotary printing machines, printing, etc., can solve the problems of untimely delivery of invoices, complicated links, and heavy processes, etc., to achieve fast printing speed and save manpower and material resources, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

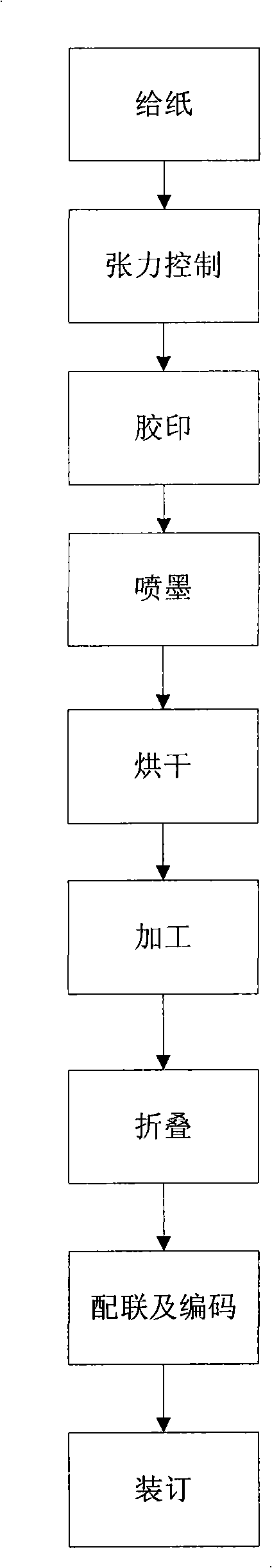

[0026] This patent adopts a commercial form printing machine, which mainly includes a paper feeding section, an offset printing section, a processing section, a folding section, an inkjet system, a drying system, and an automatic circulating water supply system.

[0027] 1. Paper feeding department

[0028] The roll paper is fixed on the paper roll shaft in the way of inflation, and the paper roll shaft is connected with the magnetic powder brake through the gear transmission. When working, the tension detection roller and the tension sensor detect the unwinding tension, and the feedback signal is sent to the tension controller. , to control the braking force of the magnetic powder brake to form a closed-loop unwinding tension control.

[0029] During printing, the unrolled paper passes through two feed rollers in an "S" shape. The feed rollers are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com