Inspection device, inspection method, inspection system and method of manufacturing color filter

A technology of inspection device and color filter, applied in the direction of measurement device, identification device, optical device, etc., can solve the problems of unsuitable for streak inspection, unsuitable, unsuitable for streak detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

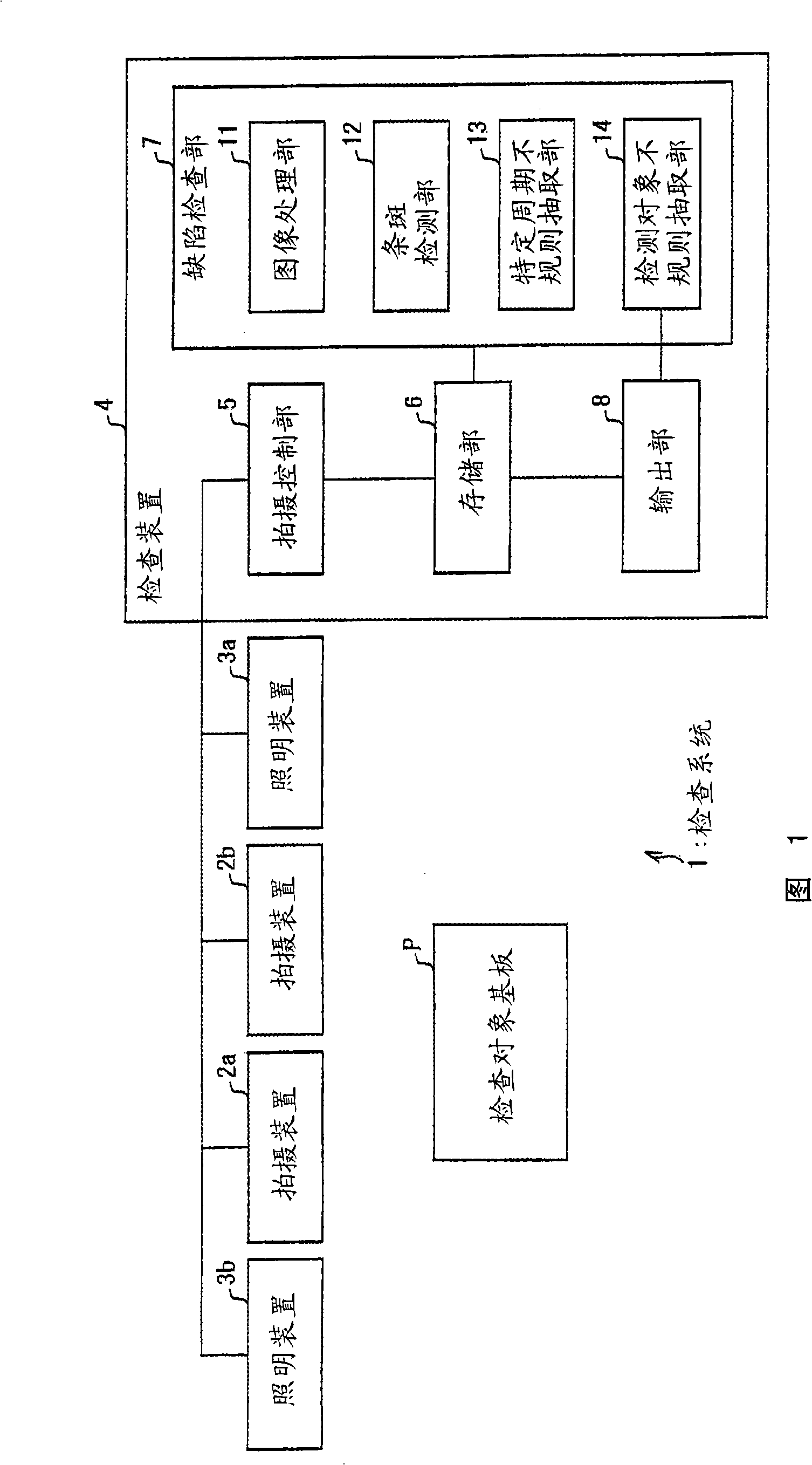

[0046] [Constitution of inspection system]

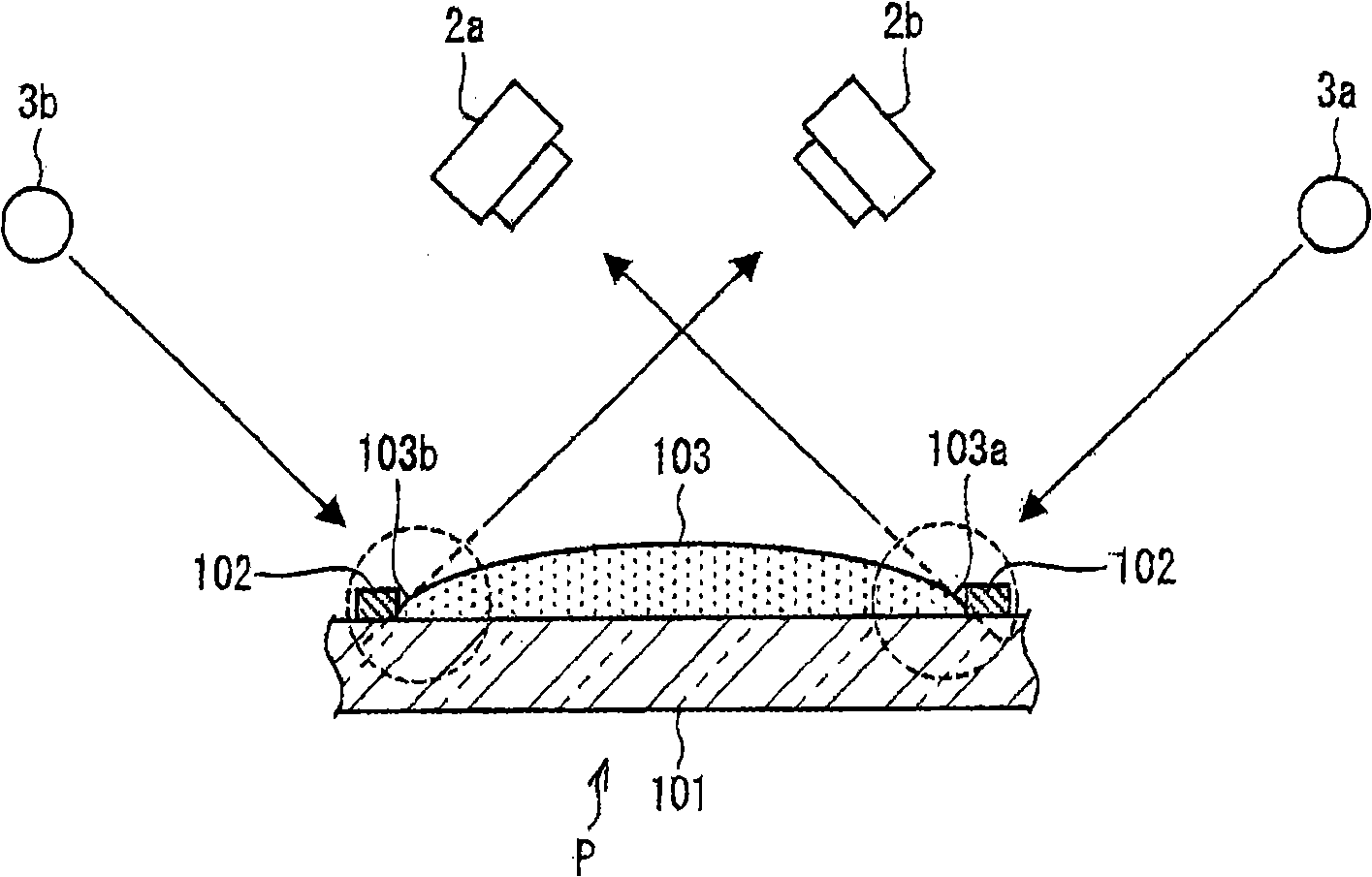

[0047] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 7 . First, an overview of an inspection system 1 according to the present embodiment will be described with reference to FIG. 1 . FIG. 1 is a block diagram showing an overview of an inspection system 1 . As shown in the figure, the inspection system 1 uses an inspection target substrate P as an inspection object, and includes an imaging device 2 a , an imaging device 2 b , an illumination device 3 a , an illumination device 3 b , and an inspection device 4 .

[0048] Here, it is assumed that the inspection target substrate P constituting the inspection target of the inspection system 1 is a color filter substrate. In the following description, the so-called color filter refers to an optical filter that allows a display device to perform color display by passing light of a specific wavelength. In addition, a color filter is formed by...

Embodiment approach 2

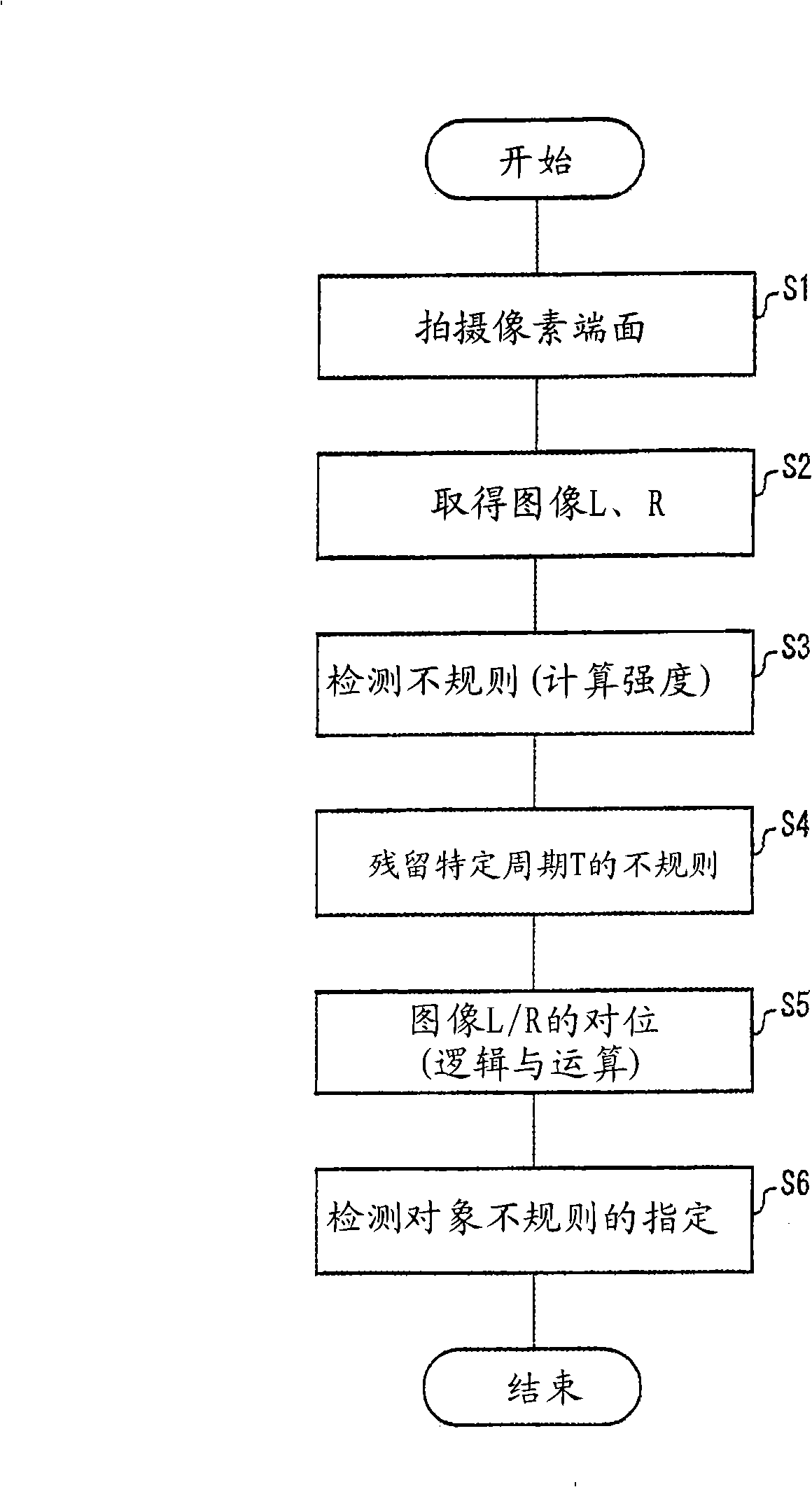

[0103] In the above-mentioned embodiment, an example was shown in which streaks were detected from one image L and one image R, but in this embodiment, the image L and the image R are respectively divided into a plurality of region, and detect instances of streaks in units of segmented regions. By dividing the image L and the image R into a plurality of regions, the detection accuracy of streaky spots can be improved. In addition, the same reference numerals are assigned to the same configurations as those in the above-mentioned embodiment, and description thereof will be omitted.

[0104] The inspection system 1 of this embodiment has the same configuration as that of the above-mentioned embodiment except that the inspection device 4 includes a region dividing unit (region dividing means), and the processing flow for detecting streaky spots is also the same as that of the above-mentioned embodiment. image 3 The processing flow shown is the same. Therefore, below, first, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com