Roof modeling function layer lean construction method

A construction method and functional level technology, applied in the direction of roof cladding, roofing, roof engineering tools, etc., can solve the problem that there is no construction method for reference, the normal direction of each point cannot be accurately determined, and the shape of the curved surface depends on manual troweling. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

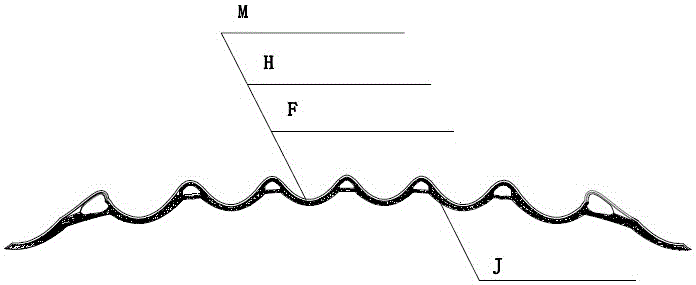

[0027] In this embodiment, the lean construction method of fan-shaped modeling function level should be figure 2 On the shell-shaped roof structure layer J shown, the waterproof layer F, the lightweight concrete insulation layer H and the surface decorative layer M are constructed in layers. The specific construction process is as follows:

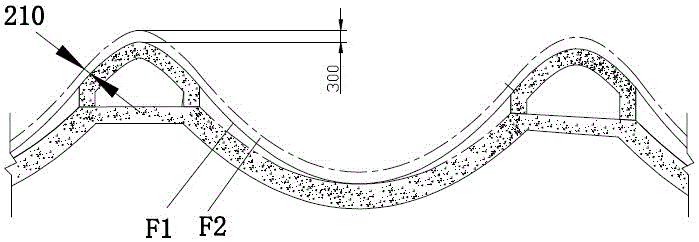

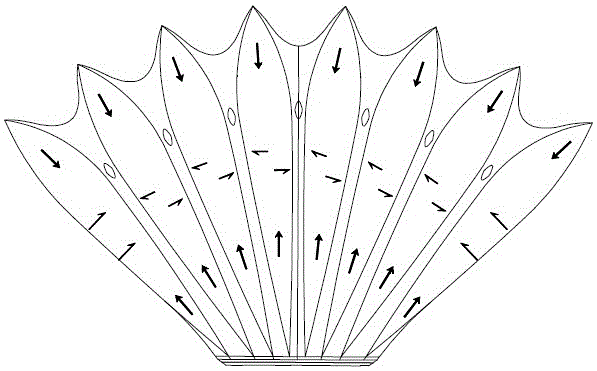

[0028] 1. Make the waterproof layer first. After cleaning the base layer and local polishing, apply a single-component polyurethane waterproof coating film. The final film thickness is not less than 3mm. Due to the ups and downs of the roof, in order to prevent the uneven thickness of the coating film due to the free flow of the highly fluid polyurethane, the coating film construction should refer to image 3 From bottom to top, and from low to high in each groove.

[0029] Then use the architectural CAD to lay out the control network, such as Figure 4 As shown, in the general plan of the shell-shaped roof, the roof control grid is est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com