Method for fabricating radio frequency ldmos devices with double metal silicides

A manufacturing method and silicide technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large sheet resistance and leakage, and achieve high output power, easy integration, and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

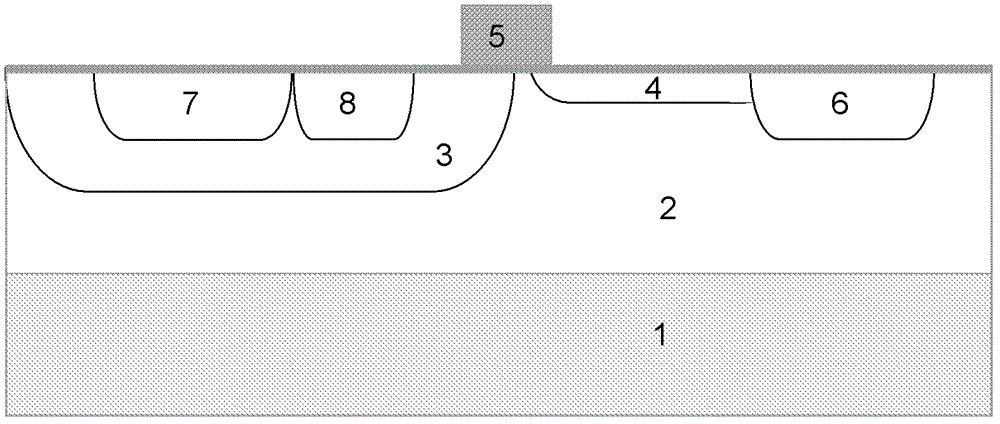

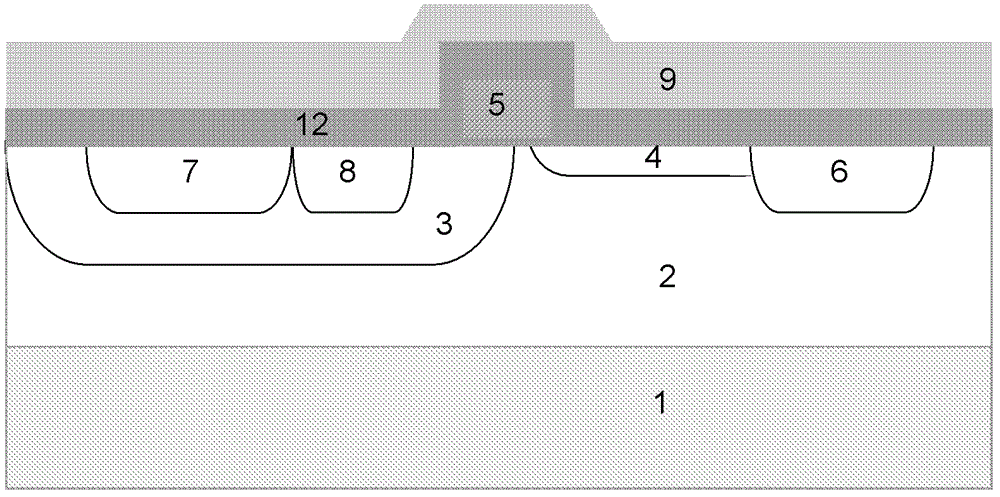

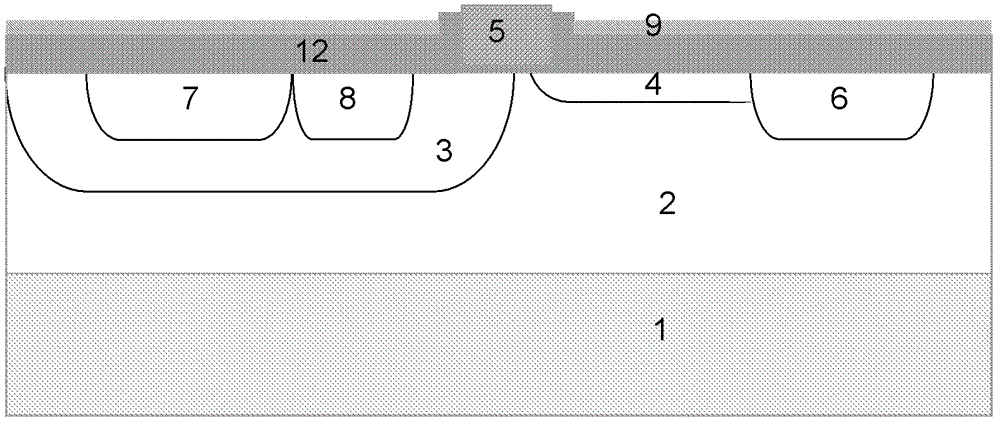

[0023] The manufacturing method of the radio frequency LDMOS device with double metal silicide of the present invention comprises the following steps:

[0024] The first step is to grow a low-doped P-type epitaxy 2 on a heavily doped P-type silicon substrate 1, grow a gate oxide layer on the P-type epitaxy 2, and deposit polysilicon on the gate oxide layer. etch to form polysilicon gate 5, and the doping concentration of P-type epitaxy 2 is 10 14 ~10 16 cm -3 ;

[0025] In the second step, ion implantation is performed on the self-aligned polysilicon gate in the P-type epitaxy 2, and a P well 3 is formed through high temperature advancement. One end of the P well 3 is located under the polysilicon gate 5;

[0026] The third step is to perform ion implantation to form N-type heavily doped source region 8 and P-type heavily doped lead-out region 7 in P well 3, and form N-type low-doped drain region 4 and N-type drain region 4 in P-type epitaxy 2. Type heavily doped drain reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com