Electric power laminated board

A power layer and circuit technology, applied to the circuit layout on the insulating board, the circuit layout on the support structure, etc., can solve problems such as electromagnetic interference, inability to isolate high-frequency resonance noise, and incomplete circuit board signals, and achieve filtering Effect of High Frequency Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The power layer board of the following embodiments can transmit DC potential and effectively filter out high-frequency noise.

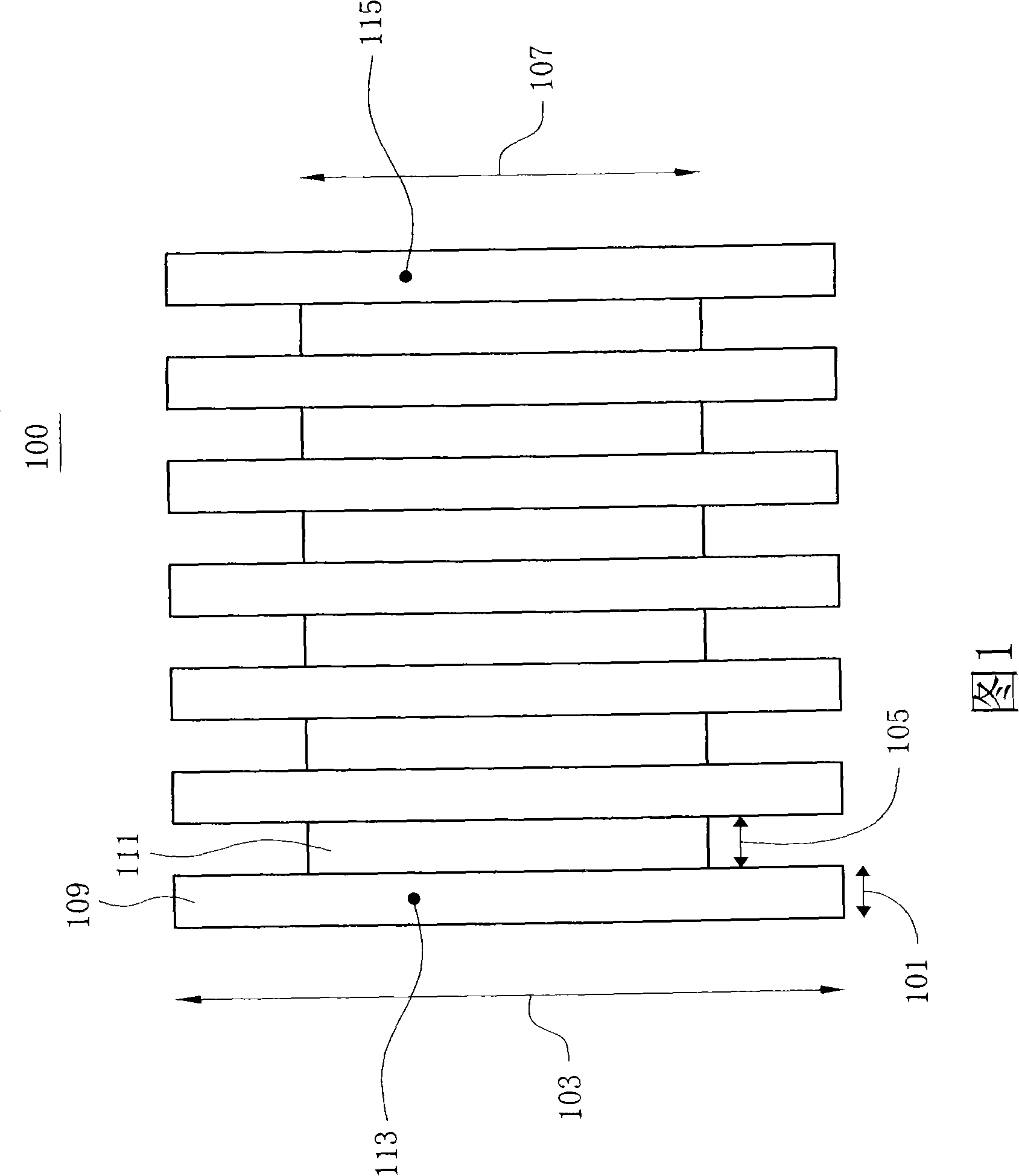

[0021] Please refer to FIG. 1 , which is a power layer board according to an embodiment of the present invention. The power layer board 100 includes a first circuit block 109 and a second circuit block 111 coupled thereto. Each circuit block can be a printed circuit board. When the potential signal is transmitted from the input terminal (noise terminal) 113 to the receiving terminal (disturbed terminal) 115, the noise can be filtered out.

[0022] The length 101 of the first circuit block 109 and the length 105 of the second circuit block 111 are related to the noise frequency to be filtered. The relationship between the length 101 and the length 105 and the noise frequency is:

[0023] L = V p 4 f ϵ ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap