Biotoxin adsorbent and production method thereof

A biotoxin and adsorbent technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of small contact area of mycotoxins, poor solubility, and unsatisfactory adsorption effect of broad-spectrum mycotoxins, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

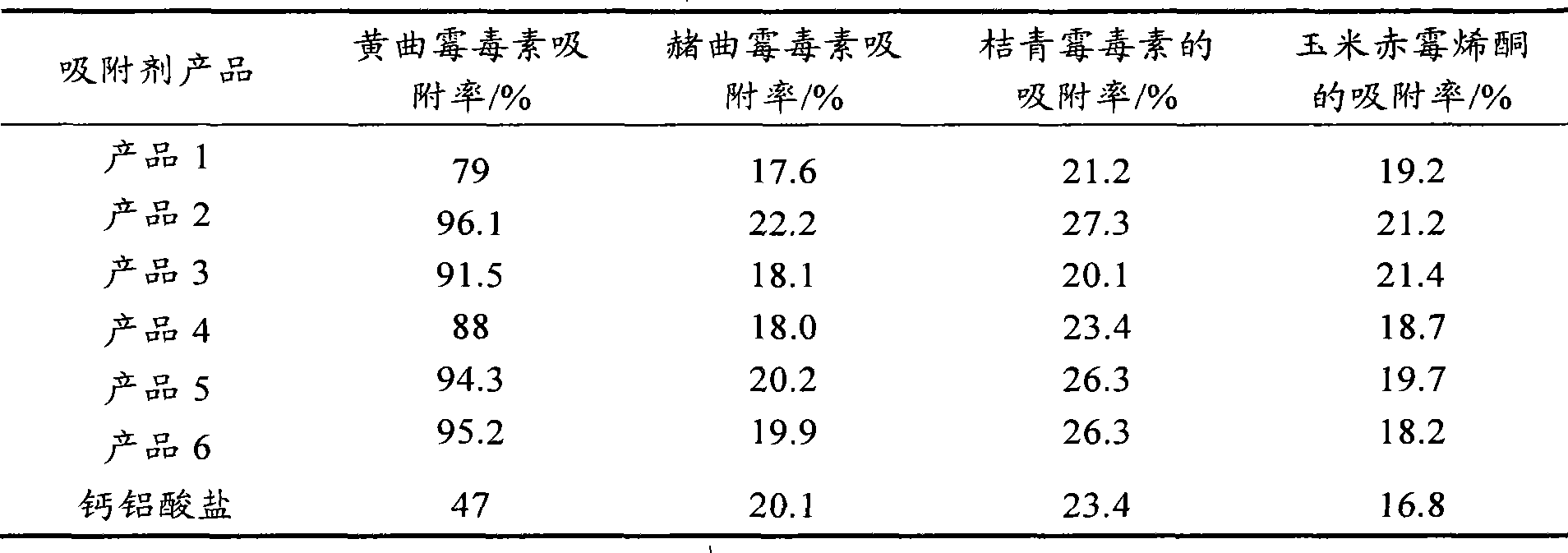

Examples

preparation example Construction

[0031] Preparation of Yeast Cell Wall Extract

[0032] The yeast cells are then lysed. Lysis can be autolysis or hydrolysis, and any of the methods mentioned in the journal literature can be used to lyse yeast cells. In the present invention, autolysis of yeast cells is performed at a temperature of about 50°C. After lysis, the resulting cell walls were centrifuged several times to remove intracellular material and concentrate the cell walls.

[0033] Cook the obtained yeast cell wall in a cooking pot at a temperature of 80-98°C for 1-2 hours, then lower the temperature to 40-60°C, adjust the pH value to 7-8, and then add an appropriate proportion of biological enzymes, the enzymes used in the process Selected from alkaline protease, mannosidase and amylase or their mixtures, preferably alkaline protease. In a specific embodiment, 1-4‰ of alkaline protease and 1-4‰ of mannosidase are used for enzymatic hydrolysis at 40-60° C. for 15-16 hours. After centrifugation, the cl...

Embodiment 1

[0038] Example 1 Preparation

[0039]300 g of Saccharomyces cerevisiae (Dalian Xinghe Yeast Co., Ltd., China) was autolyzed at a temperature of about 50° C., and the resulting cell walls were centrifuged in a centrifuge at a speed of 6000 rpm to remove intracellular matter and concentrate the cell walls. Cook the obtained yeast cell wall in a cooking pot at a temperature of 80-98°C for 1.5 hours, then lower the temperature to 40-60°C, adjust the pH value to 7-8, and then add 1-4‰ weight (based on the quality of Saccharomyces cerevisiae) of alkali protease and 1-4‰ mannosidase at 43°C for 15-16 hours. After centrifugation, the clear liquid is concentrated, and the obtained clear liquid is spray-dried to obtain hygroscopic water-soluble powder mannan oligosaccharides. Spray-dry to obtain dry powder with mannan oligosaccharide content reaching 40%-50%. The dry powder was uniformly mixed with aluminosilicate at a weight ratio of 98:2 to obtain a biotoxin adsorbent (product 1). ...

Embodiment 2

[0040] Example 2 Preparation

[0041] Autolyze 300 g of Saccharomyces cerevisiae (obtained by amplified culture of the Saccharomyces cerevisiae strain M205128 cultivated by the applicant company) at a temperature of about 50°C, and centrifuge the obtained cell wall in a centrifuge at a speed of 6000 rpm to remove intracellular matter and condense the cell wall. Cook the obtained yeast cell wall in a cooking pot at a temperature of 80-98°C for 2 hours, then lower the temperature to 40-60°C, adjust the pH value to 7-8, and then add 1-4‰ weight (based on the quality of Saccharomyces cerevisiae) of alkali protease and 1-4‰ mannosidase at 60°C for 15-16 hours. After centrifugation, the clear liquid is concentrated, and the obtained clear liquid is spray-dried to obtain hygroscopic water-soluble powder mannan oligosaccharides. Spray-drying yields a dry powder with a manno-oligosaccharide content of 48%. The dry powder and the aluminosilicate are uniformly mixed in the weight rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com