Installation method of steam heating coil for ship oil tanks

A technology of steam heating coil and installation method, which is applied in the direction of hull ventilation/heating/cooling, ship parts, ship construction, etc., which can solve the problems of high maintenance costs, shorten the construction period, ensure the integrity of sections, and make production more efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

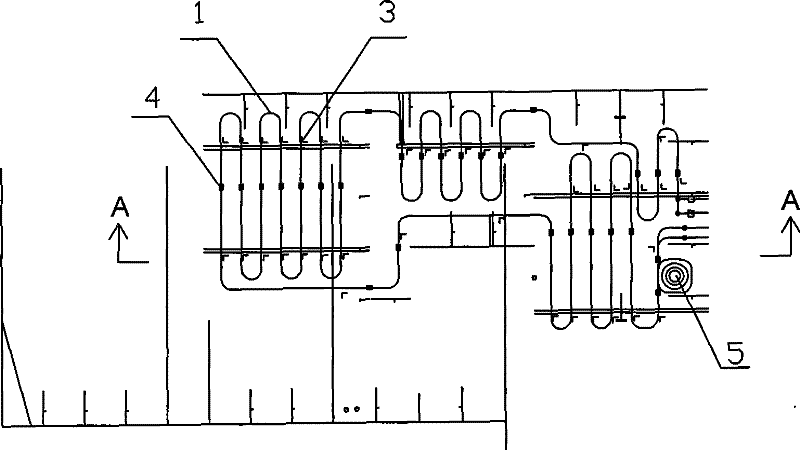

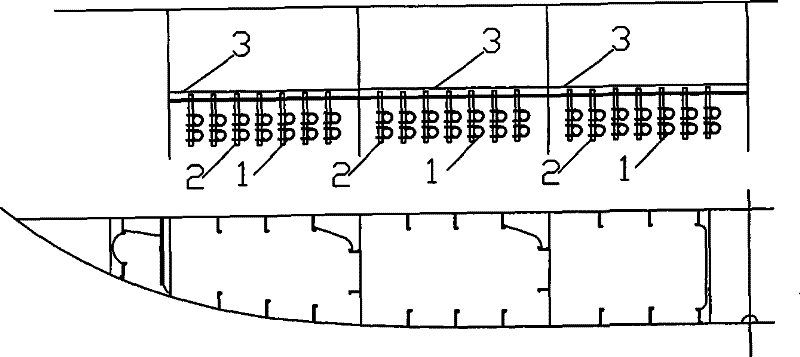

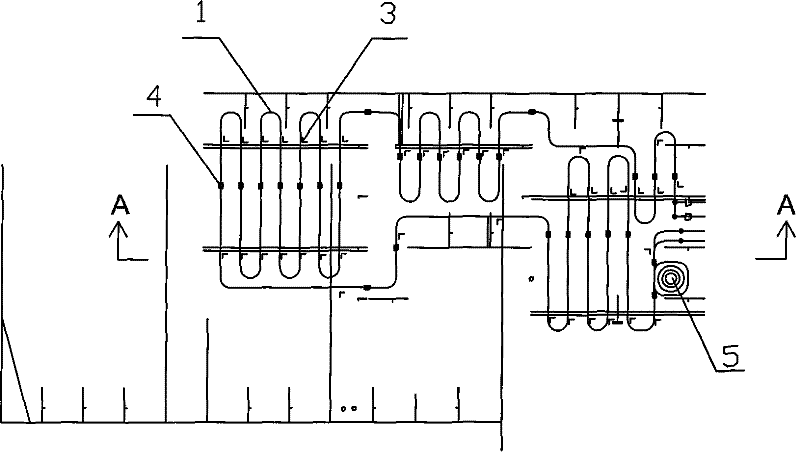

[0016] Take the 1700TEU container ship built by Wenchuan Company as an example, such as figure 1 , 2 As shown, after the section where the oil tank is located is formed, the installation of the oil tank steam heating coil 1 is started; according to the installation coordinates of the oil tank steam heating coil in the drawing, the position of the pipe support 2 is determined, and the pipe support 2 is installed on the On the large angle steel 3 specially used for installing oil tank steam heating coils; according to the installation coordinates given in the drawing, fix the first oil tank steam heating coil on the pipe support 2, and then install the second oil tank steam heating coil Insert one end of the first oil tank steam heating coil into the connecting sleeve 4 and fix the second oil tank steam heating coil on the pipe support 2 according to the coordinates, and spot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com