Guiding device for rotating mechanism of ring crane

A technology of rotating mechanism and guiding device, which is applied in the direction of traveling mechanism, transportation and packaging, and load hanging components, etc. It can solve the problems of poor neutrality of the crane, low positioning accuracy of lifting points, and fast wear, etc., so as to reduce the guiding force, The effect of easy control of the size of the gap and high positioning accuracy of the lifting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

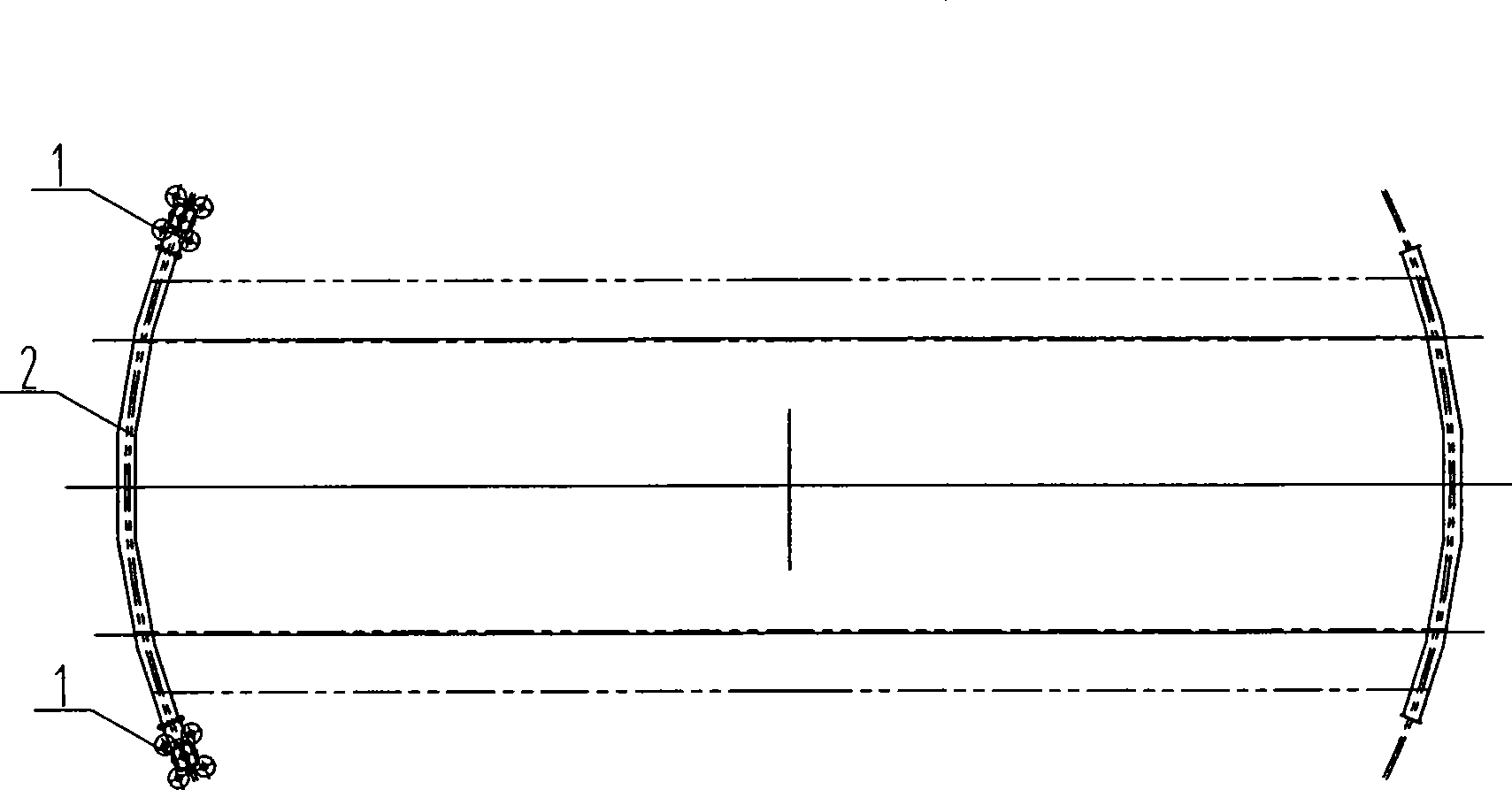

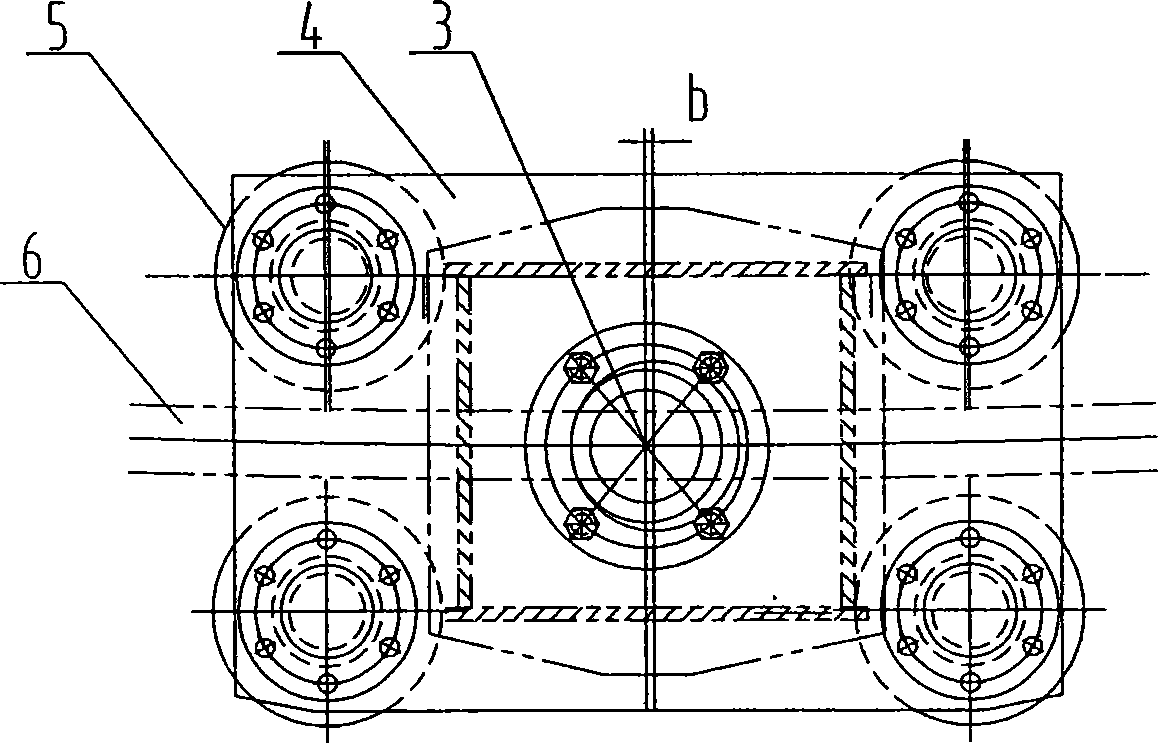

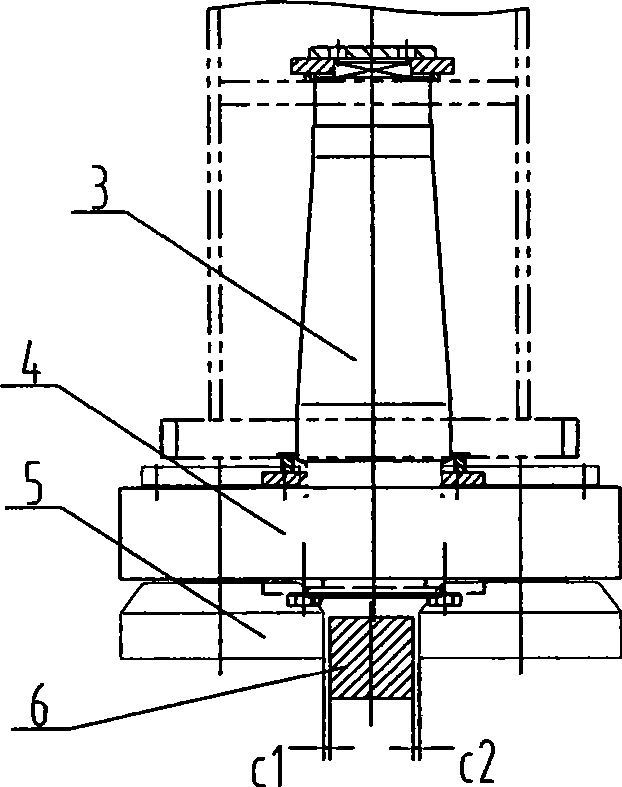

[0020] like figure 1 , 2 , Shown in 3 and 4, a kind of guiding device of the rotating mechanism of the ring crane is two groups of guide wheel devices 1 installed on the two heads of an end beam 2 of the crane, each group of guide wheel devices 1 is respectively composed of the middle mandrel 3. The installation bracket 4 and four horizontal rollers 5 are composed. The installation bracket 4 is connected with the end beam 2 of the crane, the middle mandrel 3 is fixed on the installation bracket 4, and the four horizontal rollers 5 are respectively fixed on the On the mounting bracket, its installation position is that two horizontal rollers 5 are located on the inboard of the circular track 6, and the other two horizontal rollers 5 are located on the outside of the circular track 6, and the central mandrel 3 and the horizontal roller sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com