Motor control device for driving sliding frame of flat-knitting machine

A technology of triangular seat carriage and control device, which is applied in the direction of AC motor control, control system, optimized efficiency control at low load, etc., can solve problems such as shortened service life, achieve the effect of reducing load and avoiding deterioration of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

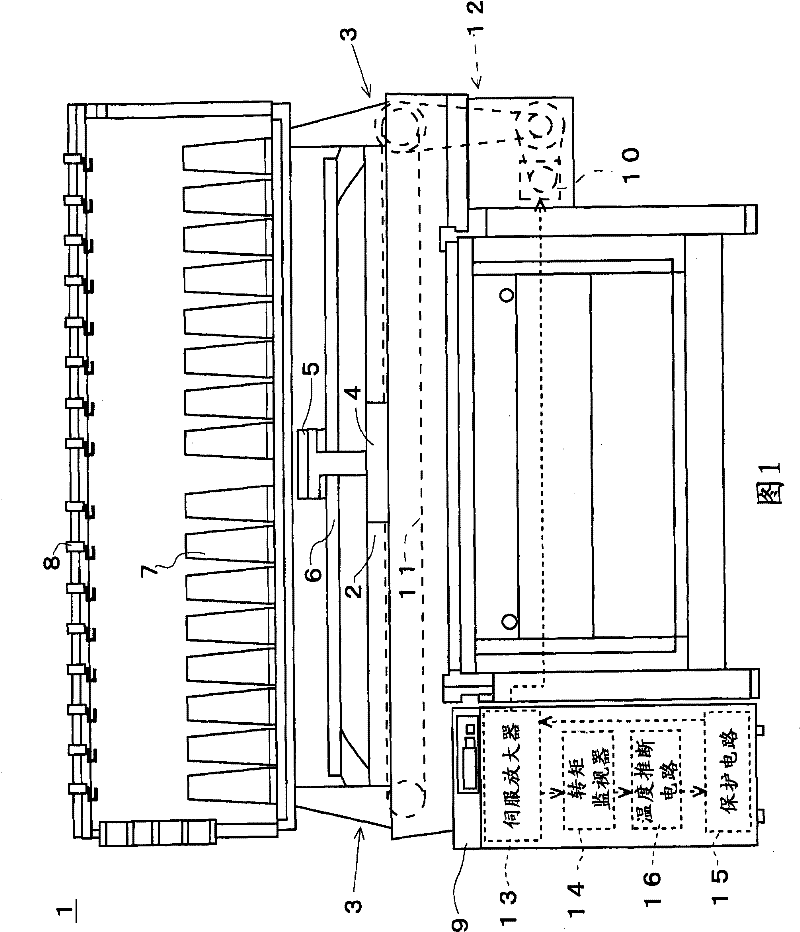

[0039] figure 1 A schematic appearance configuration of a flat knitting machine 1 according to an embodiment of the present invention is shown. The flat knitting machine 1 has needle beds 2 at the front and back, and the needle beds 3 in the middle face each other. A carriage 4 is provided on the front and rear needle beds 2 respectively, and the carriage 4 is connected to the carriage 4 by a bridge 5 at the tooth gap 3 . The carriage 4 is driven to reciprocate in the left-right direction in the figure, that is, the longitudinal direction of the needle bed 2 . A plurality of yarn guide rails 6 are erected above the crest 3 . A yarn guide (not shown) serving as a yarn supplying member for supplying the knitting yarn to the needle bed 3 is movably supported on the yarn guide rail 6 . The bridge portion 5 is straddled on the yarn guide rail 6, and can be driven by selecting one yarn guide among a plurality of yarn guides. When performing plating knitting, etc., sometimes a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com