Laser cutting device of embroidery machine and laser embroidery integrated machine thereof

A technology of laser cutting and laser cutting head, which is applied to the mechanism of embroidery machines, embroidery machines, auxiliary devices, etc. It can solve the problems of hindering the embroidery frame, disadvantages, pollution, etc., and achieves easy installation and adjustment, reasonable structure, and precise cutting operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

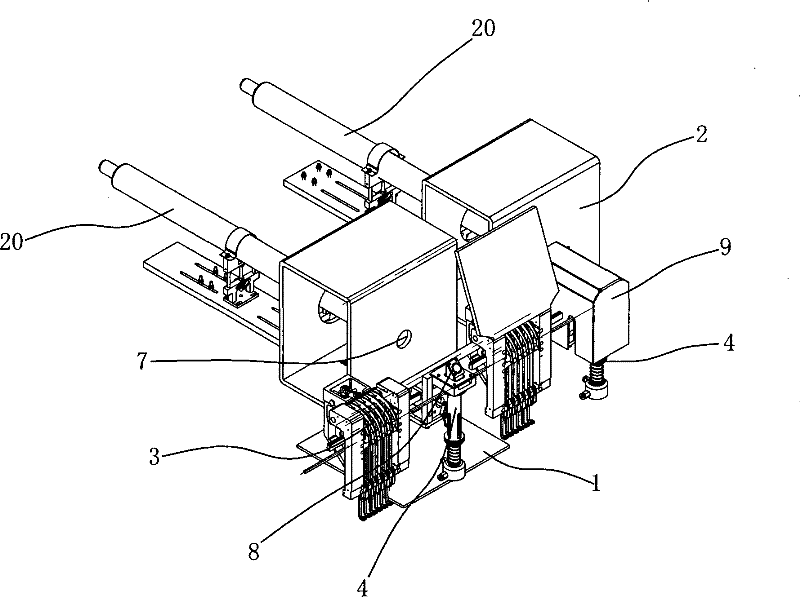

[0028] Example: such as figure 1 As shown, the frame is provided with a platen 1 and a crossbeam 2 above the platen 1, and the platen 1 is provided with an embroidery frame (not shown in the figure) which is controlled by a computer to move two-dimensionally in the horizontal direction. 2 is provided with two groups of flat embroidery heads 3, and a laser cutting head 4 is also fixed on the side of each group of flat embroidery heads corresponding to the beam. The flat embroidery heads 3 and the laser cutting heads 4 are arranged alternately. The spacing between adjacent parallel heads and laser cutting heads is equal.

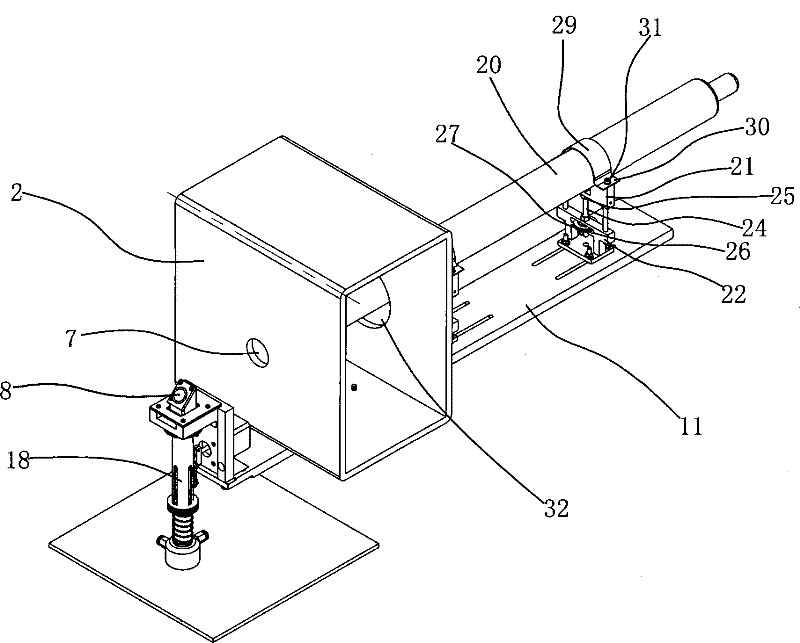

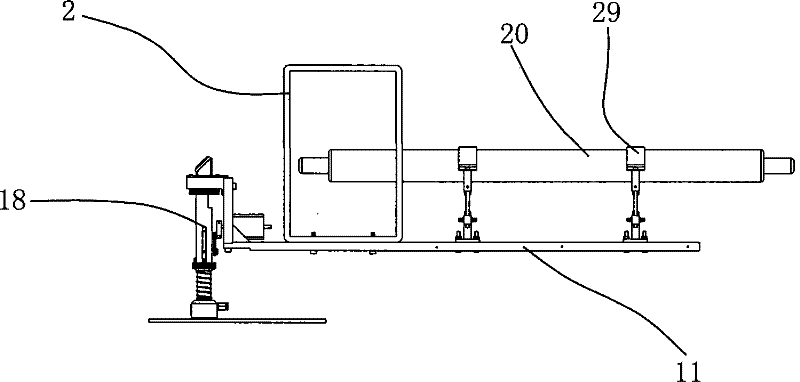

[0029] like figure 2 , image 3 and Figure 4 As shown, the support frame 11 is installed and fixed on the lower surface of the crossbeam 2, and the two ends of the support frame 11 extend to the front and rear sides of the crossbeam 2 respectively, and the support frame 11 is provided with four parallel elongated main mounting holes. 12 (see Image 6 ),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com