Pile extension under water

A technology of locking device and rope connection, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., to achieve the effect of simple structure, continuity and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

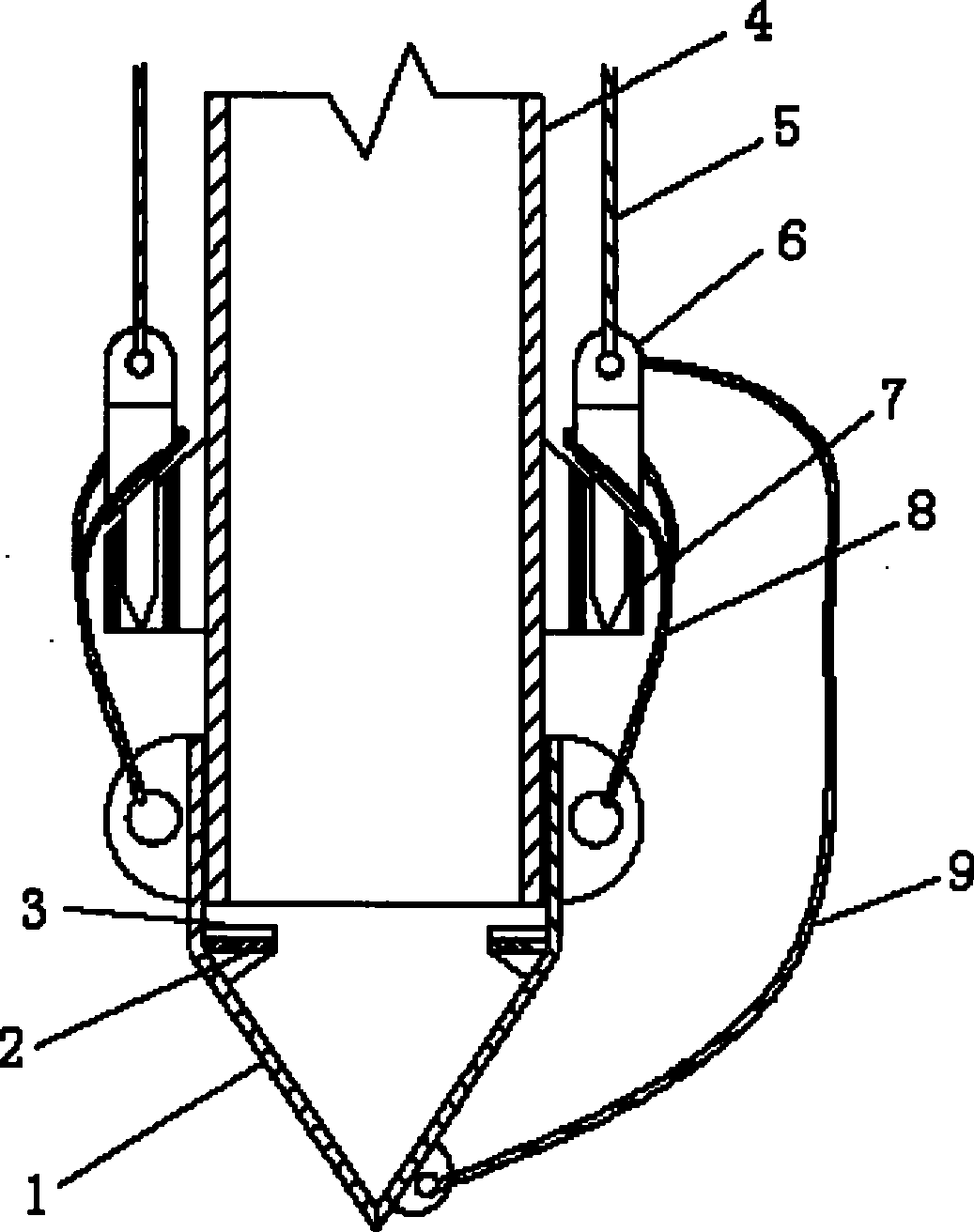

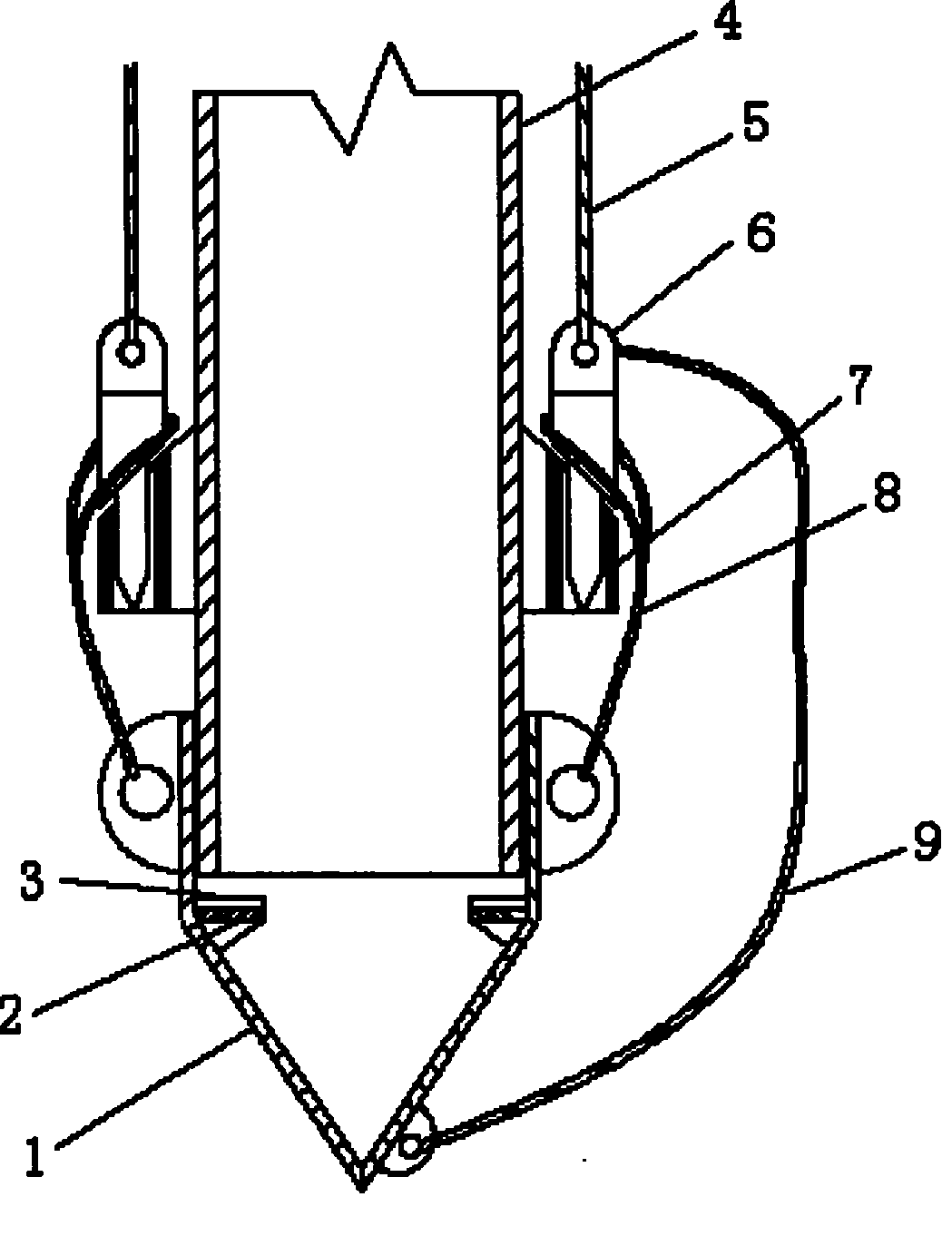

[0010] See the accompanying drawings, the underwater piling device includes: a sealing sleeve 1 whose inner diameter is larger than the outer diameter of the conduit 4 and whose bottom is conical. The sealing sleeve 1 is provided with an inner flange 2 and a rubber pad 3. There are two steel wire rope sleeves 8 on the outer wall of the sealing sleeve, a bolt 6 connected to the steel wire rope 5 and a latch sleeve 7 on the conduit 4. The tapered bottom of the sealing sleeve 1 is provided with a recovery steel wire rope 9 , Recovery steel wire rope 9 is connected on the latch 6.

[0011] During use, the sealing sleeve 1 is installed on the lower opening of the conduit 4, the latch 6 is installed in the latch sleeve 7 on the conduit 4, the steel wire rope sleeve 8 on the outer wall of the sealing sleeve 1 is buckled on the latch 6, and the steel wire rope sleeve 8 is adjusted. length, so that the inner flange 2 of the sealing sleeve 1 is tight against the bottom opening of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com