Hollow mold for filling cast-in-situ concrete

A technology of hollow carcass and cast-in-place concrete, which is applied to the on-site preparation of building components, formwork/formwork/work frame, building components, etc., which can solve the inconvenience of production, inconvenient assembly line production, and inability to arrange hollow carcass And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

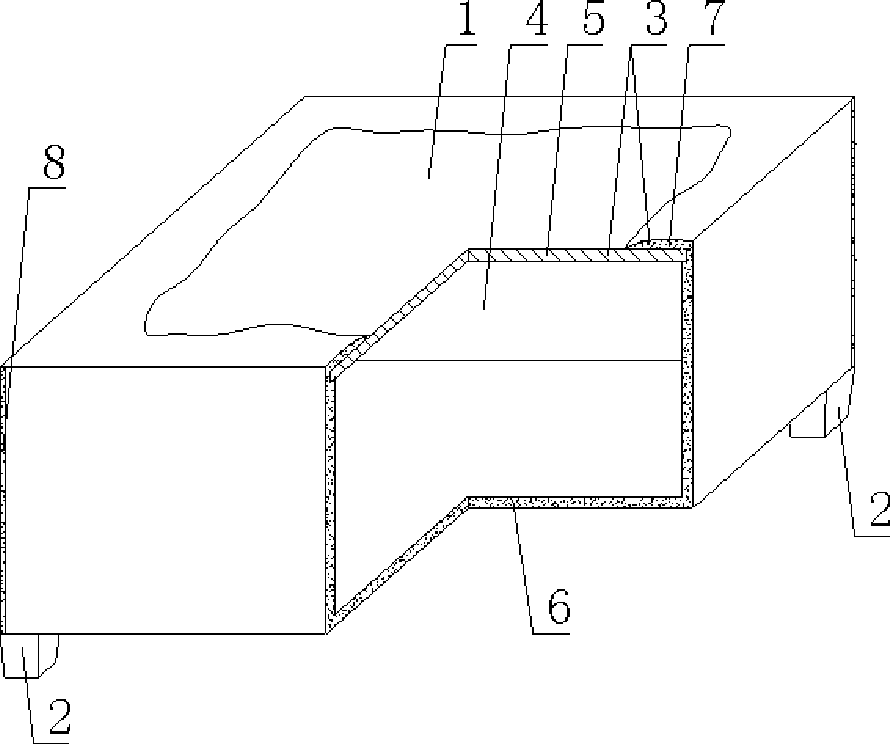

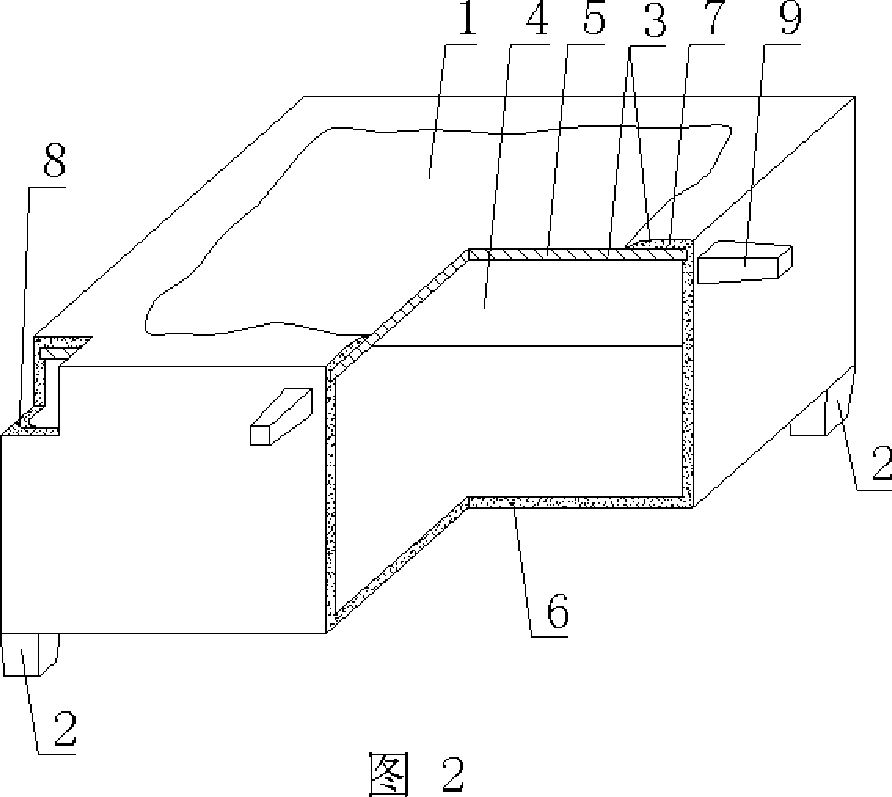

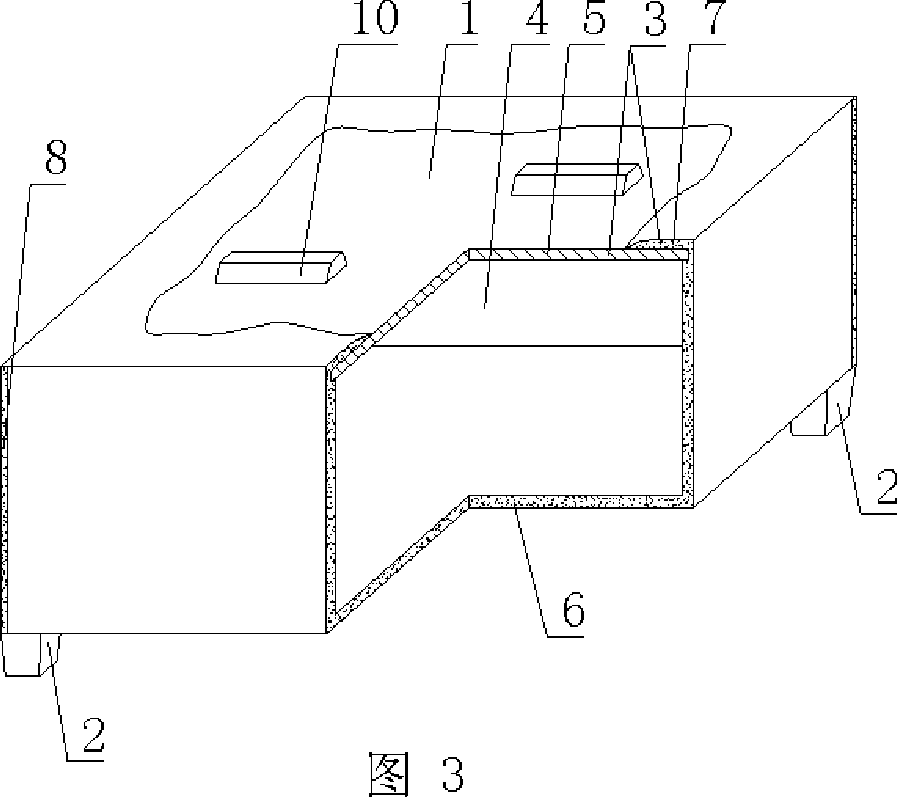

[0062] As shown in the accompanying drawings, the present invention includes a hollow carcass 1 and a supporting foot 2. The supporting foot 2 is arranged on the outer wall 3 of the hollow carcass 1. The supporting foot 2 is a split foot or a movable foot, and the outer wall 3 is enclosed to form a hollow The hollow carcass 1 of the cavity 4 is characterized in that the hollow carcass 1 is a hexahedron, the hollow carcass 1 is formed by a prefabricated outer wall 5 closing the opening of the basin-shaped embryo body 6, and the prefabricated outer wall 2 is the top outer wall. The outer wall 5 is superimposed with an existing plaster layer 7, and the five-sided embryo body of the basin-shaped embryo body 6 is an integral conjoined embryo body. Within the layer 7 there are reinforcements 12 . In each drawing, 1 is a hollow carcass, 2 is a support foot, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com