Ultrasound phased array cased well and front sounding integration detecting method

An ultrasonic phased array and integrated detection technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of poor accuracy of impression technology, poor detection effect, and low resolution, and achieve the goal of overcoming precision poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

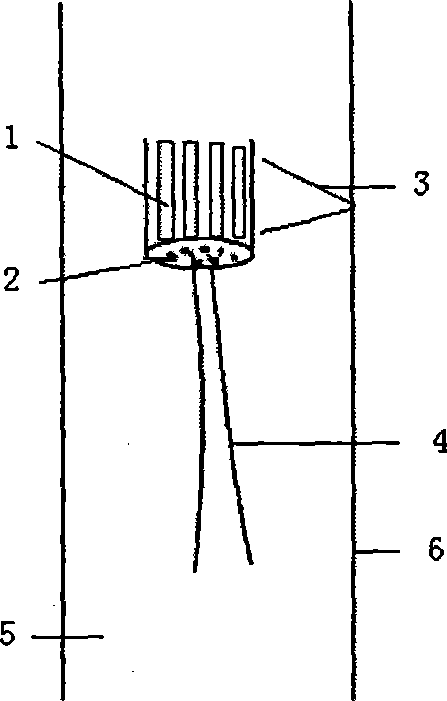

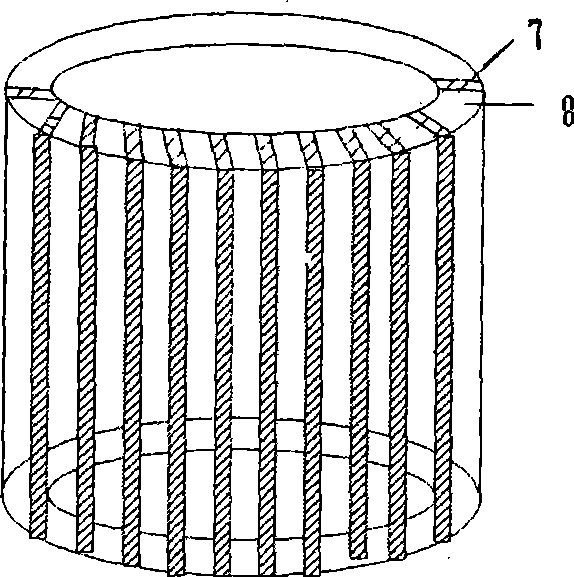

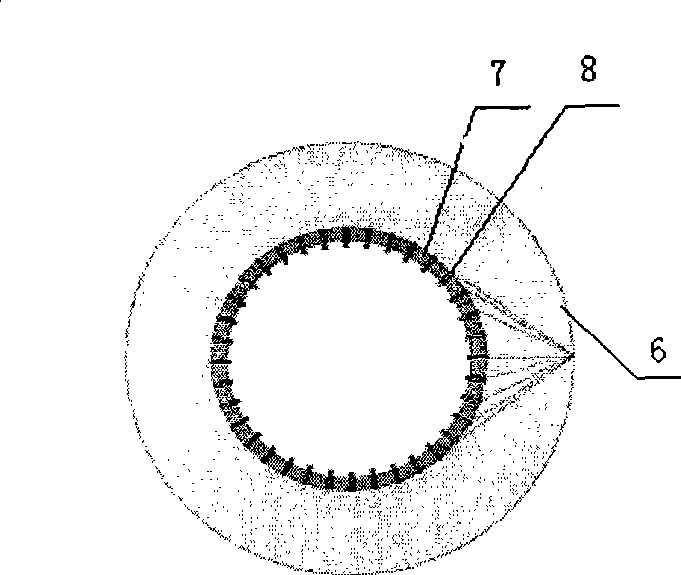

[0011] exist figure 1 Among them, the integrated detection method of ultrasonic phased array casing wellbore and front visitation is to realize the integration of oil well circumference scan and downhole front visitation measurement technology through the cylindrical phased array scan ultrasonic transducer, and complete the borehole survey at the same time. The transducers for the peripheral wall scanning imaging and the front visit imaging measurement consist of the well scan phase control probe 1, the front visit phase control probe 2, the axial focused sound beam 3, the lower focused sound beam 4, the transducer unit 7, the segmented medium 8, Reflected acoustic beam 9, signal excitation control module 10, phase control delay control module 11, phase control delay superimposition and processing module 12, A / D sampling module 13: the integrated detection method can be used to simultaneously measure oil well (or casing ) 360-degree ultrasonic phased array scanning imaging of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com