Central thread passing pipe twisting machine

A tube stranding machine and wire-type technology, which is applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problem that the tube stranding machine cannot realize the multi-layer stranding, hard wire or stranded wire stranding. The problem that the wire cannot pass through and the number of twisted cables is not applicable, so as to achieve the effect of small moment of inertia, low equipment failure rate, and reduced equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

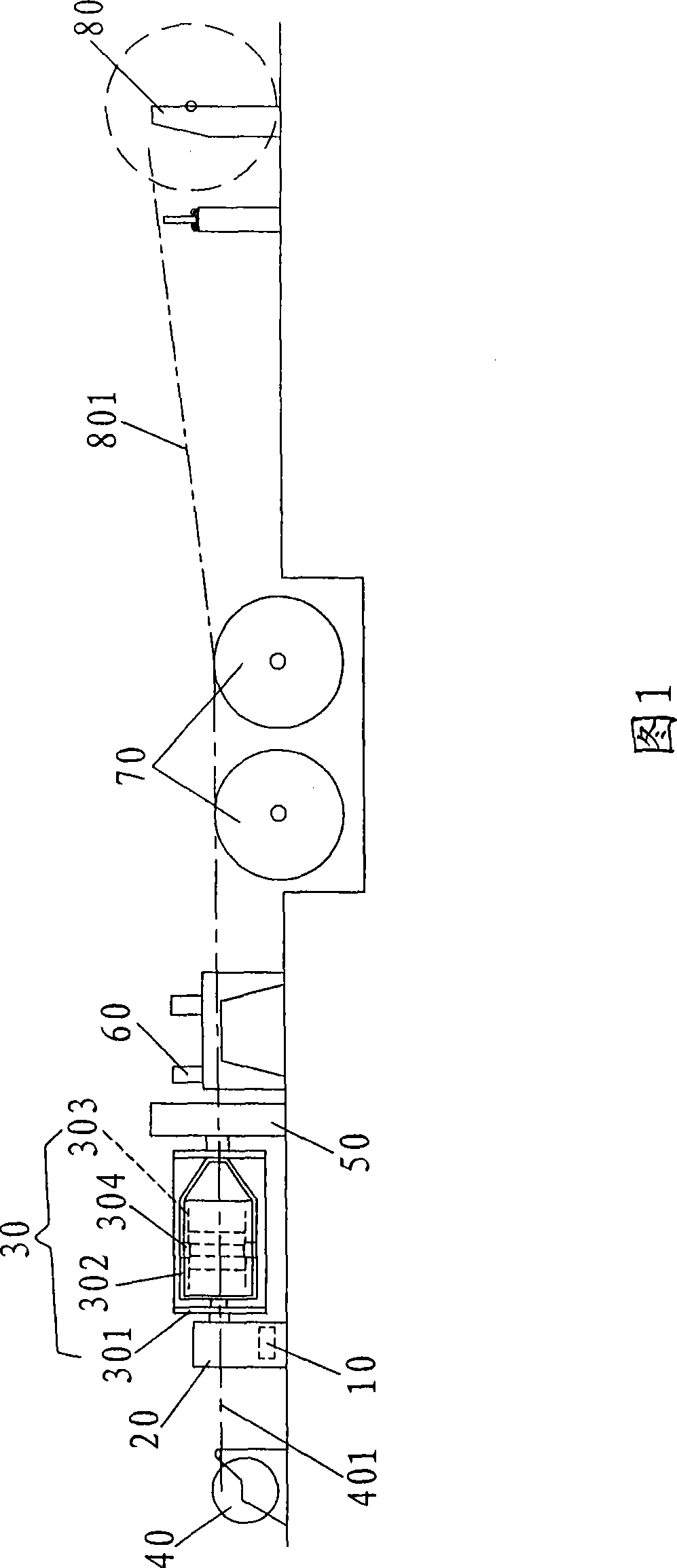

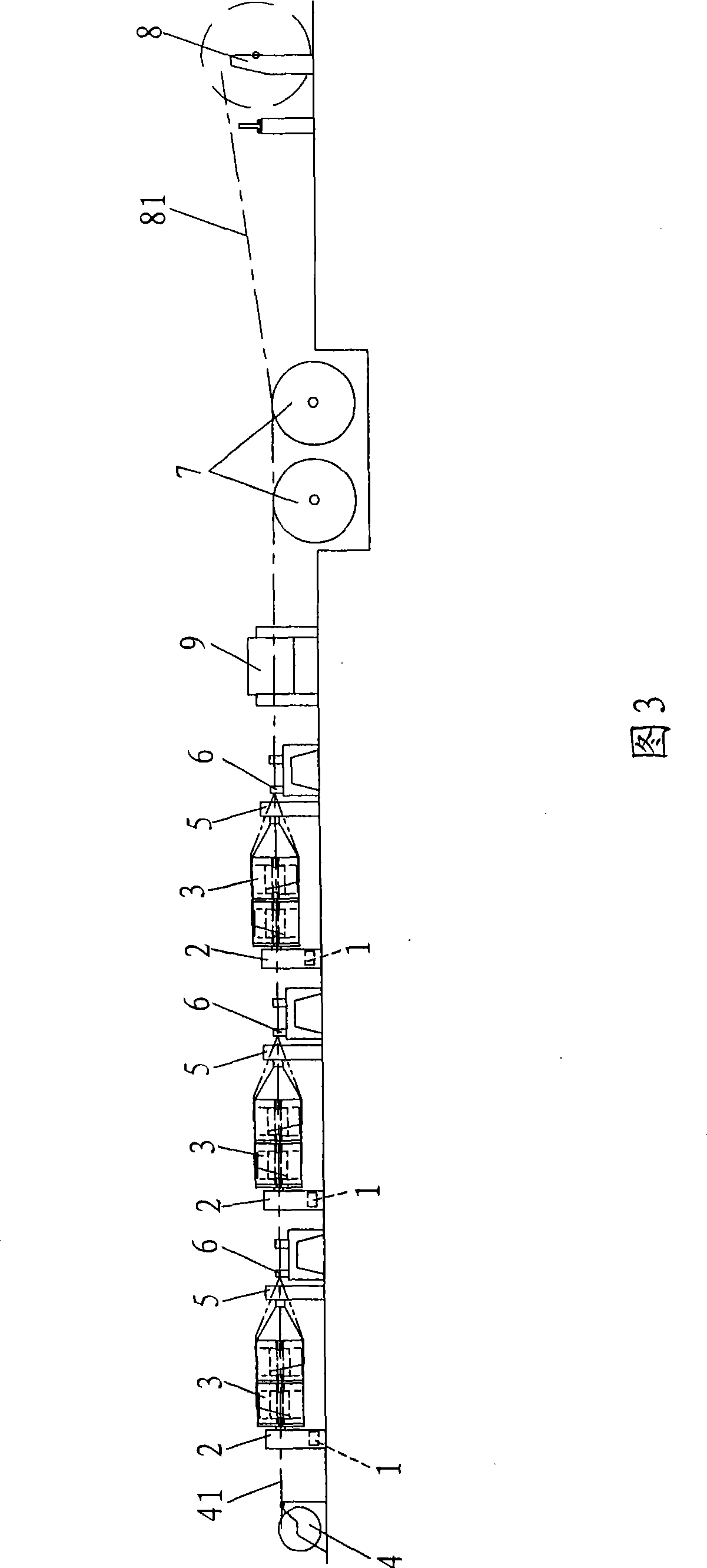

[0050] Referring to Fig. 3, it is a preferred embodiment of the present invention, the central threading type pipe stranding machine mainly includes a motor 1, a gearbox 2, a twisted body 3, a central pay-off frame 4, a wire distribution tray 5, and a wire collection mold 6. Traction machine 7, wire take-up rack 8. The stranded body 3 includes a pipe body 31 and a pay-off reel 33 . The pay-off reel 33 is assembled in the pipe body 31 through the reel clamping device.

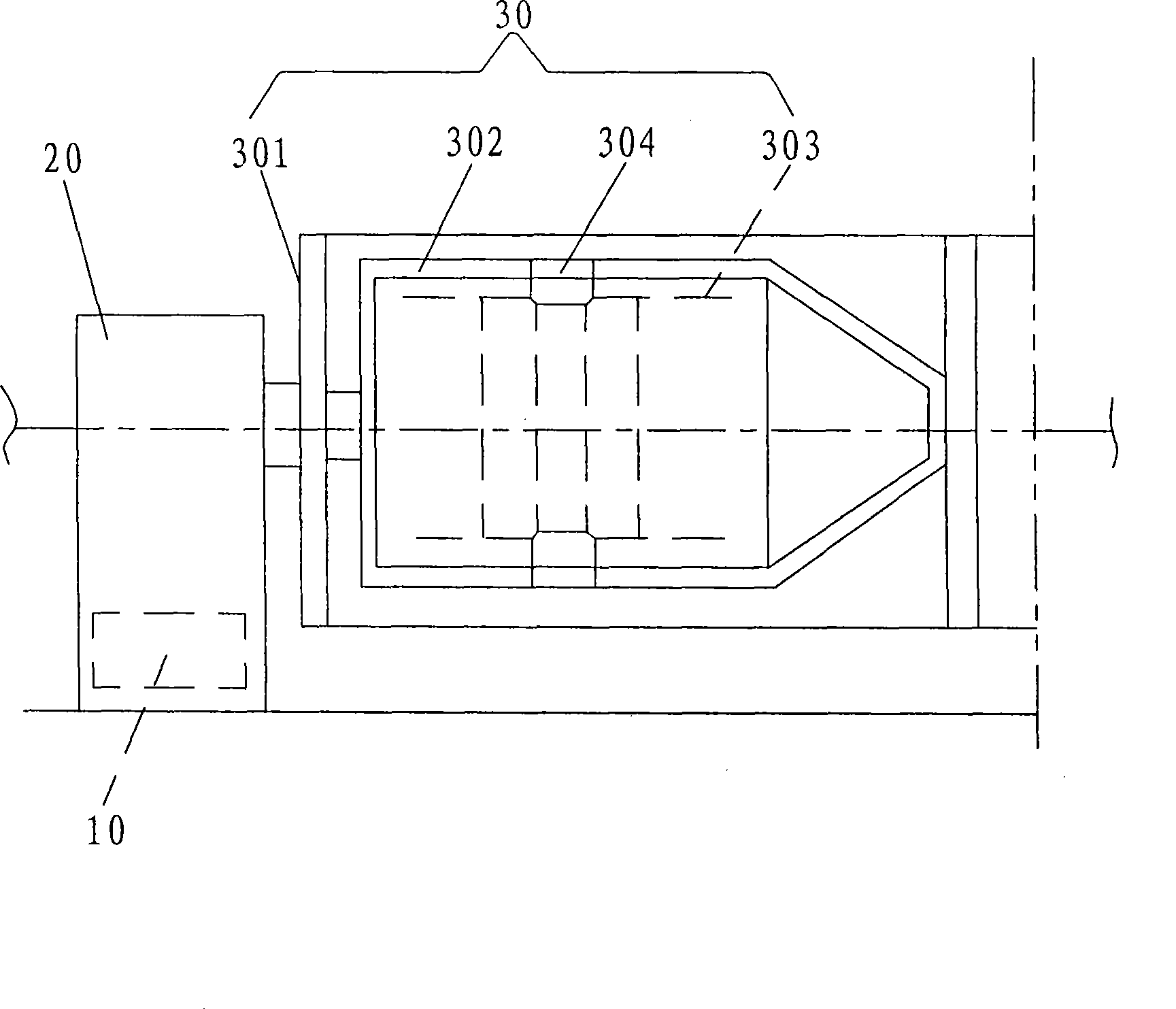

[0051] The key of the present invention is as Figure 4 Shown: the axis of the pay-off reel 33 is designed to coincide with the center line 41 (i.e. the center line of the production line) released by the pay-off reel on the center pay-off stand 4, and the corresponding pay-off reel 33 in the twisted body 3 is also equipped with a replacement Guide wheel mechanism 32. In this way, the central hole of the pay-off reel 33 is used for threading when threading, which solves the problem that the traditional tube s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com