Modelling pearl nucleus for pearl culture and preparation method thereof

A production method and pearl core technology are applied to the modeling pearl core for pearl cultivation and the field of production thereof, which can solve the problems of abrasion of the mantle of the pearl oyster, and achieve the effects of reducing the breeding cost, high economic value and high quality.

Inactive Publication Date: 2010-11-10

谢绍河 +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But its fly in the ointment is: because its shaped bead core body is still made of hard plastic, the phenomenon that the mantle of the pearl oyster will be worn out when the pearl is cultivated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

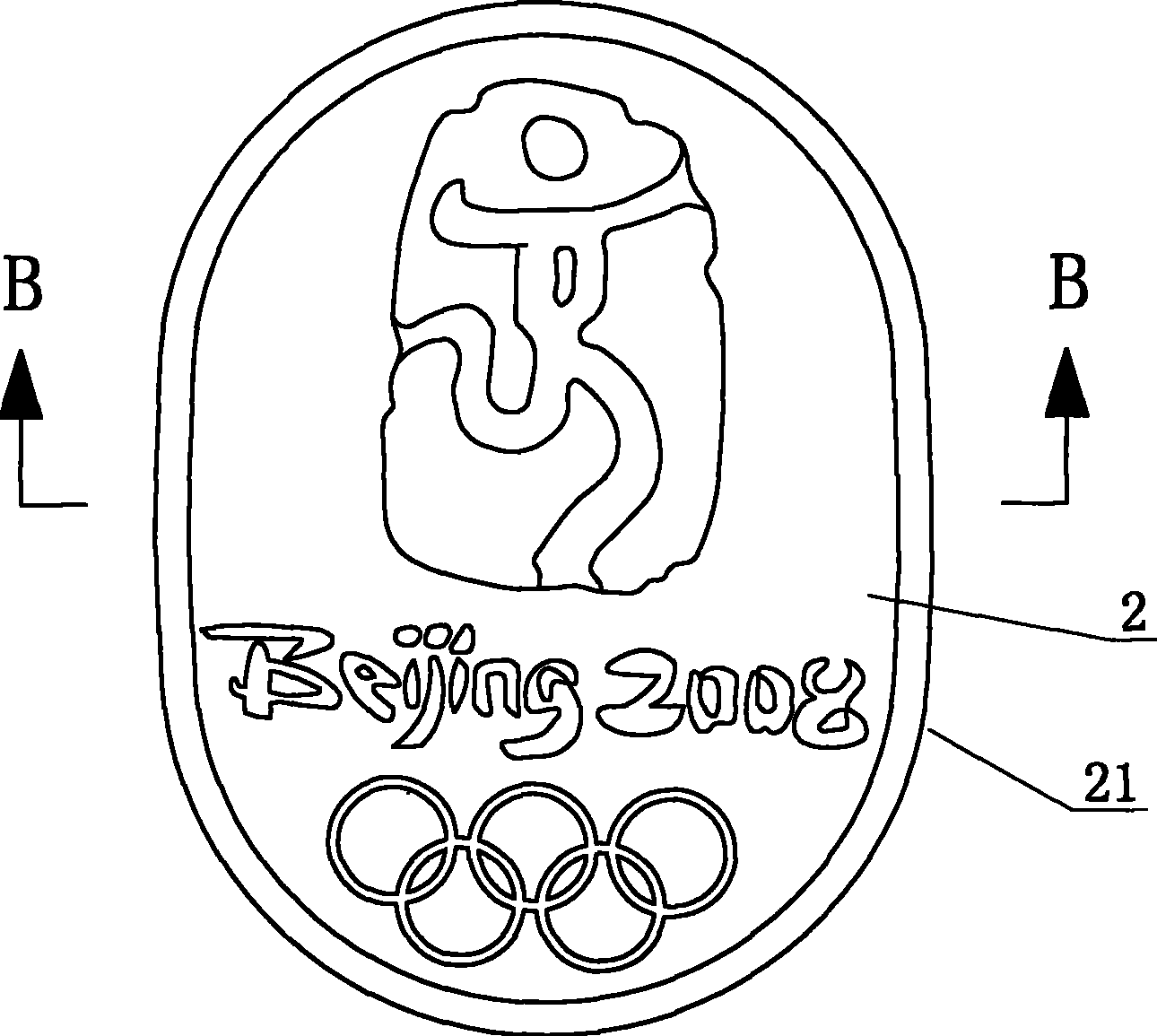

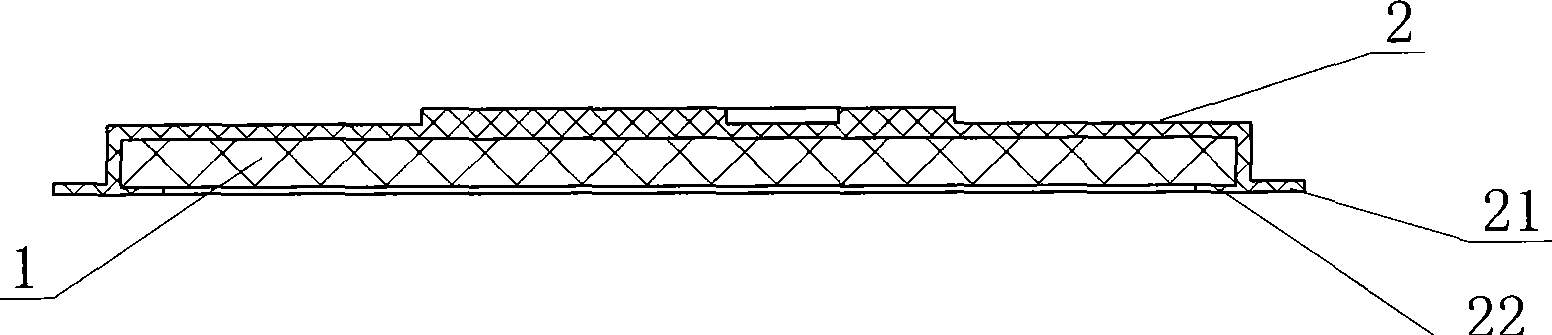

The invention relates to a moulding pearl nuclear used for pearl culture, which comprises a moulding pearl nuclear body. The moulding pearl nuclear used for pearl culture is characterized in that the moulding pearl nuclear body is a composite moulding nuclear body consisting of a soft moulding outer die and a hard moulding inner die which is positioned inside the soft moulding outer die and has the function of supporting. Due to adoption of the structure of the composite nuclear body consisting of the soft moulding outer die and the hard moulding inner die, the advantages of soft materials and hard materials are skillfully combined together, so as to make the moulding pearl nuclear have the advantages during the process of pearl culture: not only the combination tightness of the pearl nuclear and conchs can be effectively improved but also mantles of pearly shellfishs are difficult to frazzle and the bead rate is high; and simultaneously the overall moulding of beads can be guaranteedto be regular and have strong depth perception, and the economic value is high. The invention also relates a method for manufacturing the moulding pearl nuclear. The moulding pearl nuclear and the method can be widely applied to the culture of various pearls.

Description

A kind of shaped pearl core for pearl culture and its production method technical field The invention relates to a pearl core, in particular to a shaped pearl core for pearl cultivation and a manufacturing method thereof. Background technique In the production of known molding pearls at home and abroad, the structure of its molding pearl core is generally a simple molding pearl core body, and the method for making the molding pearl core is roughly two kinds: one is to use impression glue, paraffin wax, PVC It is made of soft materials such as soft plastic and rubber. Due to the poor quality of the material itself, the mold core is often easily deformed due to the certain curvature of the pearl-growing shell during the breeding process, resulting in irregular beads and no three-dimensional effect. Strong, low value, especially when producing larger shaped pearls, the deformation is more obvious; the other is shaped pearl cores carved from hard materials such as shells, brig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A01K61/00

CPCY02A40/81

Inventor 谢绍河谢郁

Owner 谢绍河

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com