Fuel rod forming machine for garbage

A technology of fuel rods and forming machines, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., which can solve the problems of being unsuitable for domestic waste disposal sites, complicated processing methods, and frequent failures, and achieves simple structure, High production efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

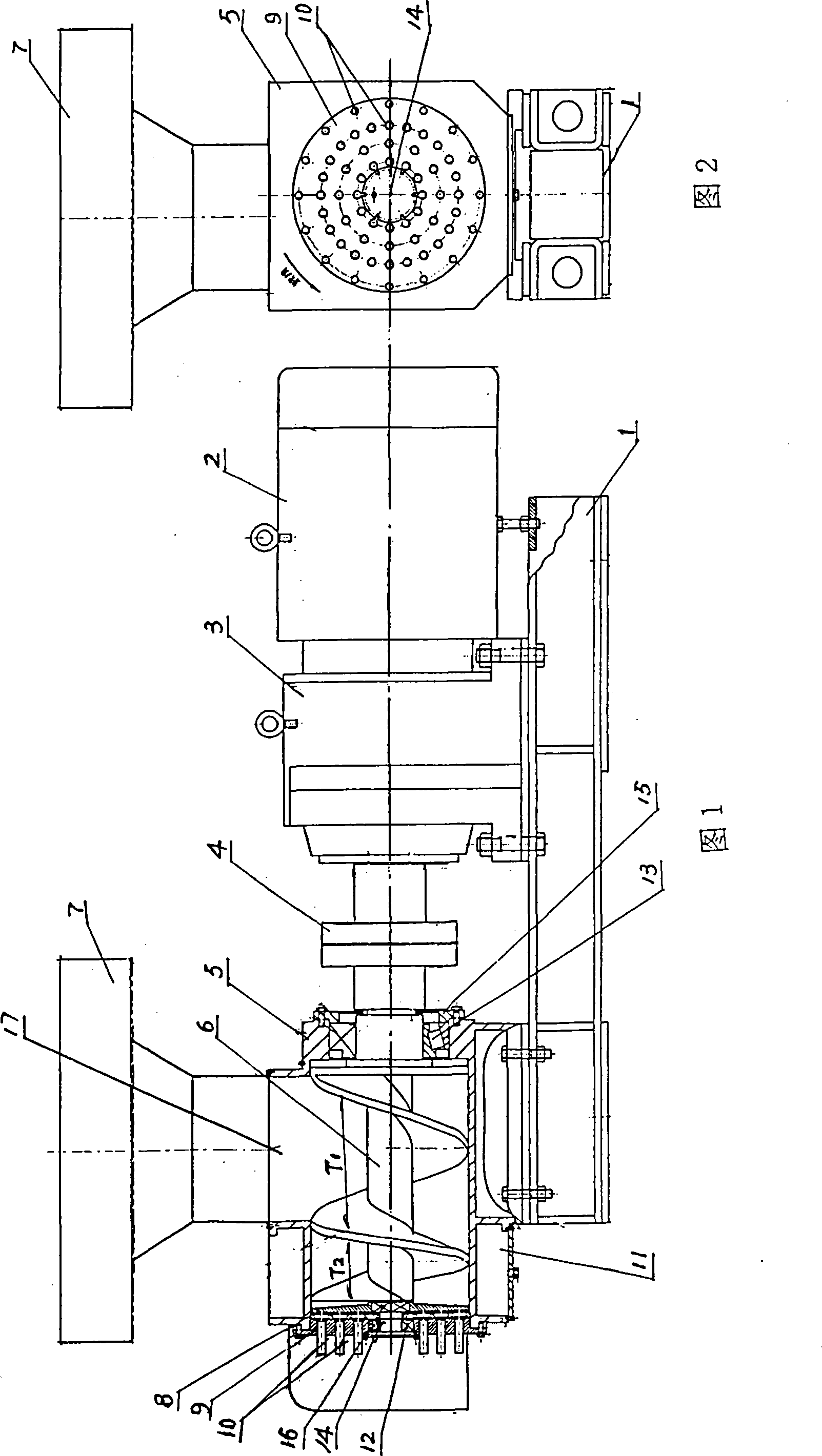

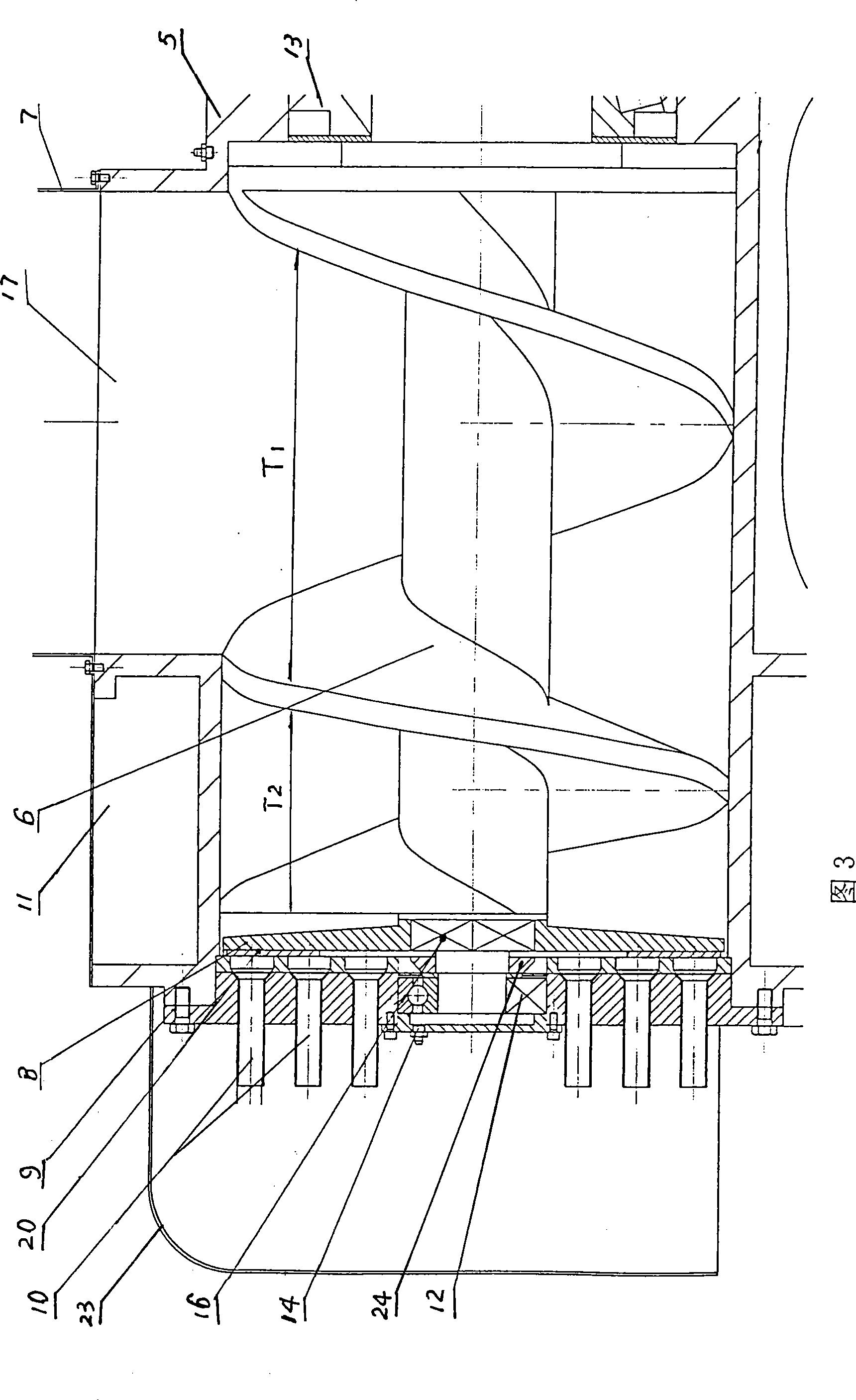

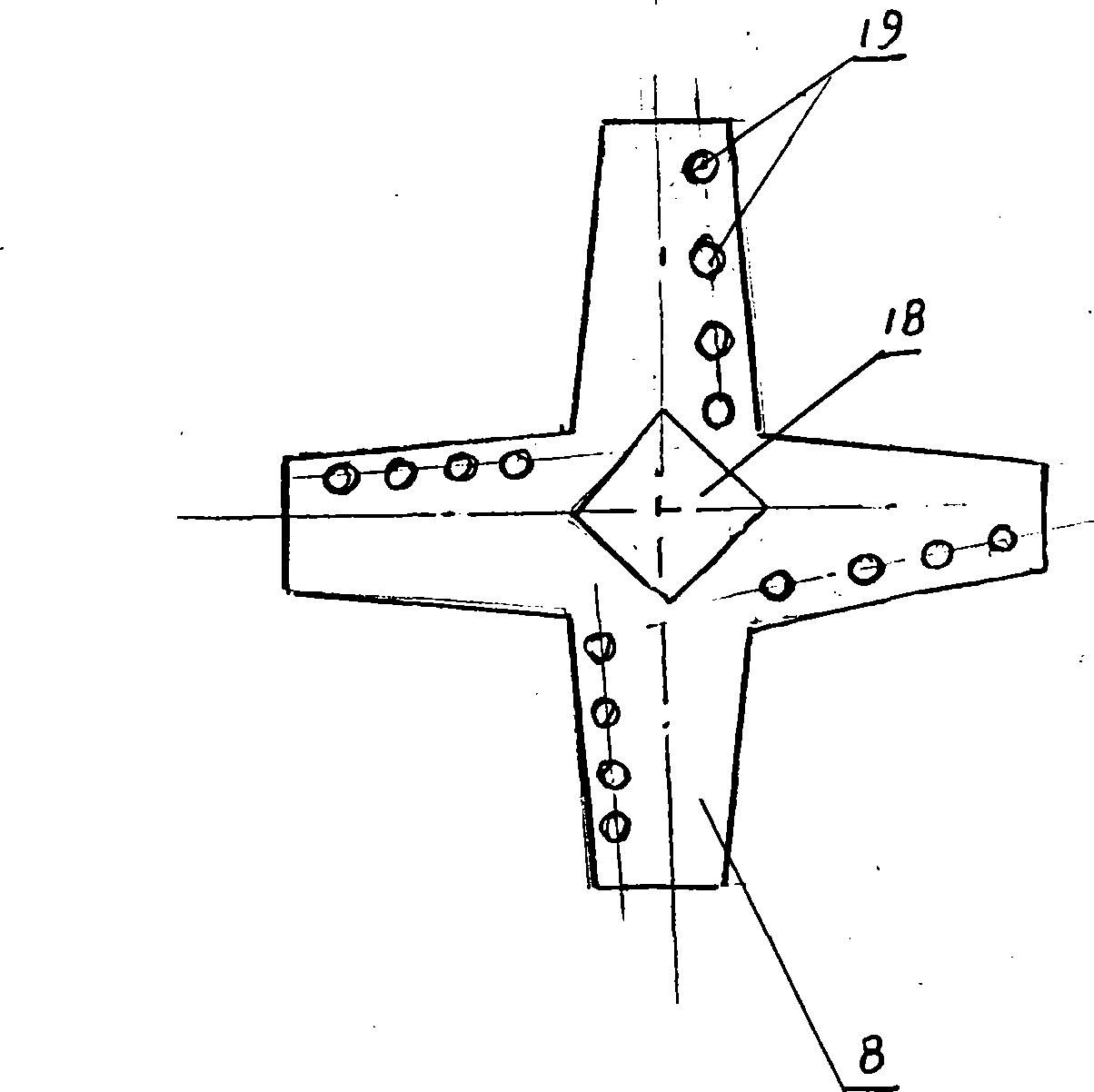

[0015] With reference to accompanying drawing 1~5, the fuel rod molding machine for refuse is made up of base 1, motor 2, speed reducer 3, coupling 4, casing 5, screw rod 6, hopper 7, cutter plate 8, forming plate 9, forming tube 10. The wear-limiting retaining ring 24 and the outer casing 23 are composed.

[0016] A motor 2 and a reducer 3 are installed at one end of the base 1, and the motor 2 and the reducer 3 are integrated into one body. Several horn-forming tube holes are arranged on the top, and forming tube 10 is housed in the forming tube hole, and the forming tube hole is a horn-forming tube hole, and the forming tube is a horn-forming tube 10. The middle part of the forming plate 9 is provided with a bearing seat, the screw rod 6 is installed in the box body 5, the front end of the screw rod 6 is equipped with a front bearing 12, the rear end of the screw rod 6 is equipped with a rear bearing 13, and the front bearing 12 at the front end of the screw rod is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com