Fixture for forming characters or designs on surface of circular column workpiece

A technology for cylindrical workpieces and characters, which is applied to the field of text or pattern forming tooling on the surface of cylindrical workpieces, can solve the problems of irregular fonts, difficulty in applying cylindrical workpieces, and high labor intensity for manual printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

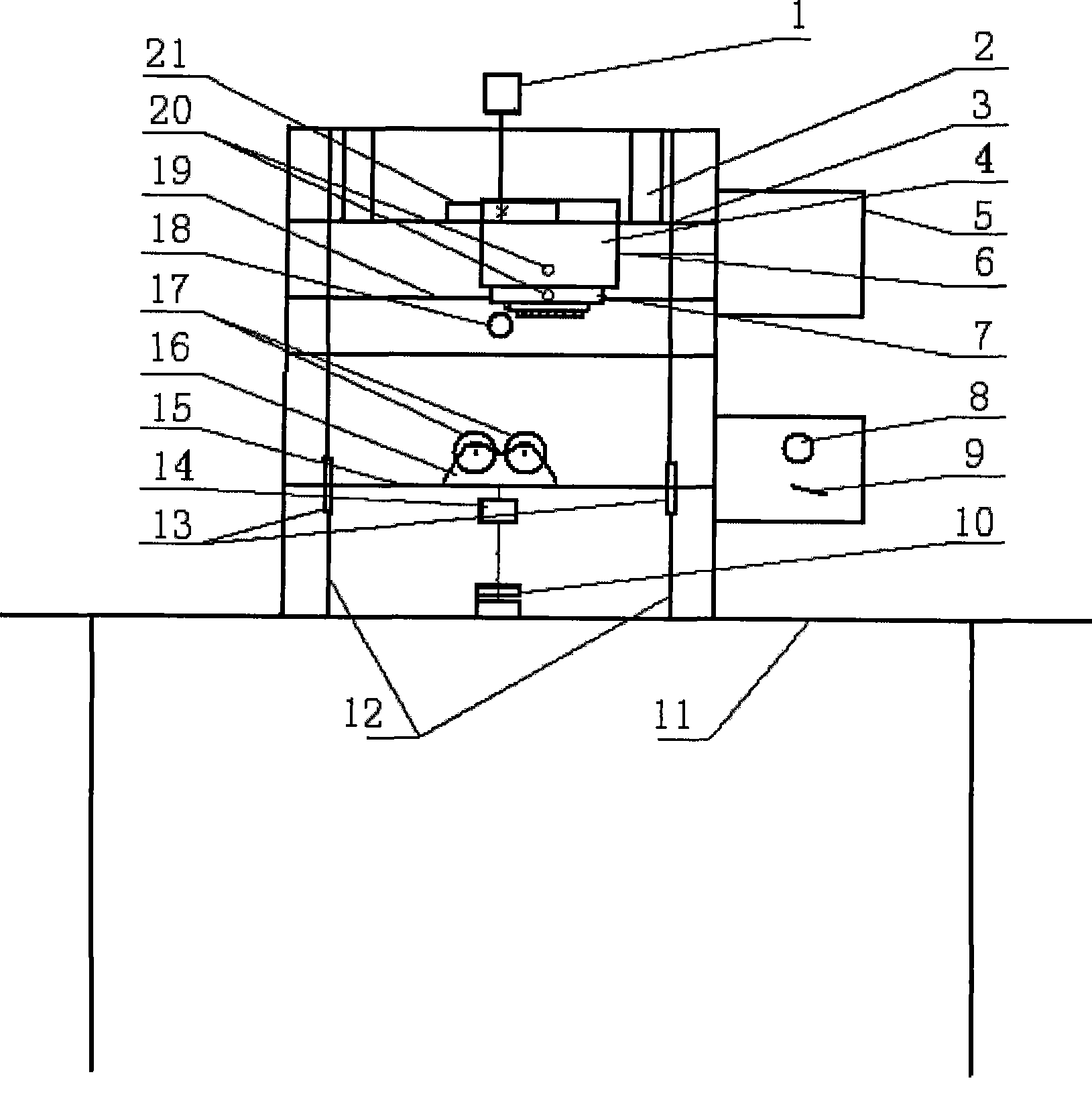

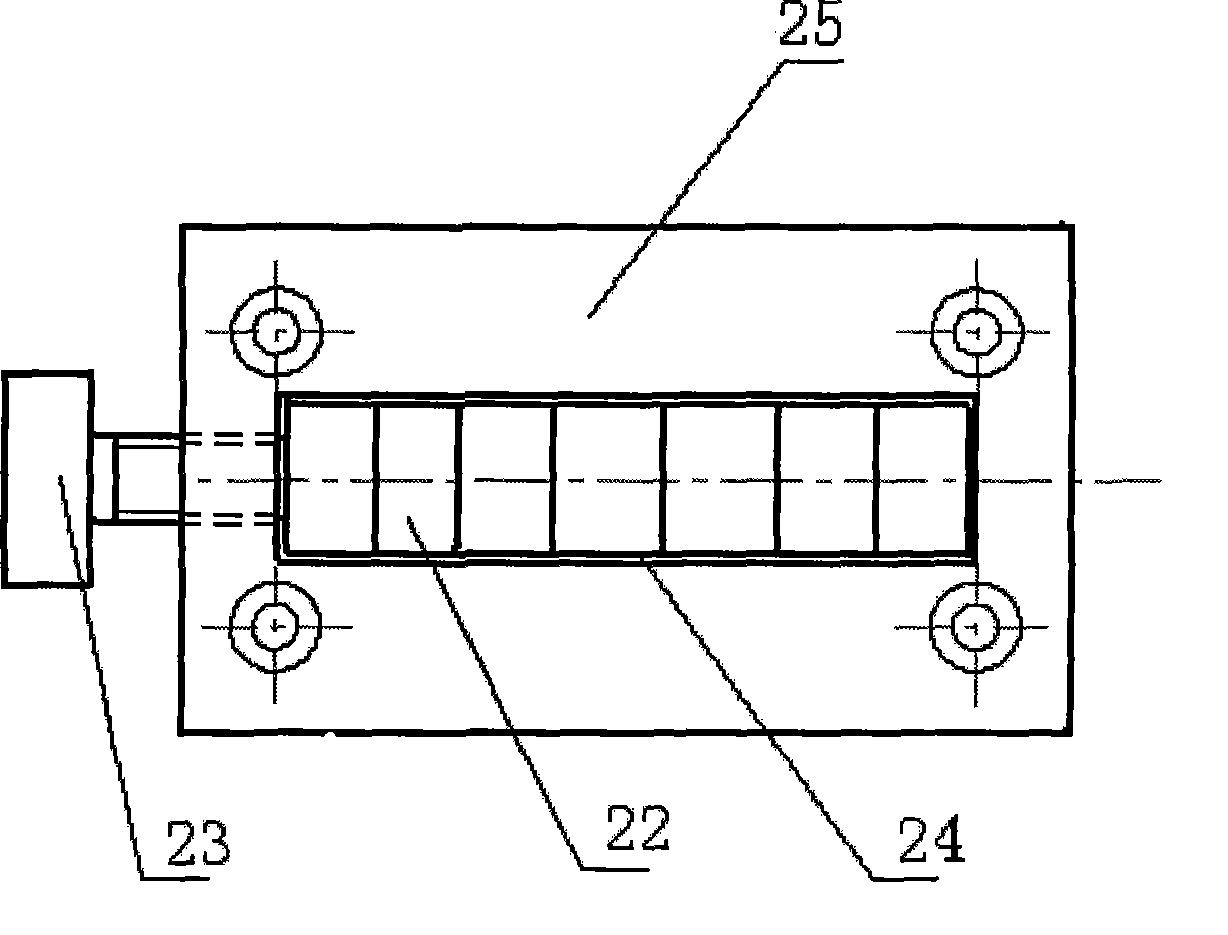

[0013] Such as figure 1 , figure 2 As shown, a tool for forming characters or patterns on the surface of a cylindrical workpiece includes a machine base 11, a bracket 2, a vertical guide rail 12, a horizontal linear guide rail 3, a supporting plate 15, a support plate 19, an adjusting nut 1, a rack and pinion pair 21, a slide Block 4, cylinder 5, cylinder piston rod 6, quick-change font mechanism 7, reset button 8, toggle switch 9, lock nut 10, guide sleeve 13, lower adjusting bolt 14, bearing seat 16, rolling bearing 17, side adjustment Bolt 18, cylinder 5, cylinder piston rod 6, slider 4 connected to the end of cylinder piston rod 6, pneumatic controller, horizontal linear guide rail 3, adjustment nut 1 and rack and pinion pair 21 form a pneumatic slider mechanism, slider 4 Set on the horizontal linear guide rail 3, the pneumatic controller includes a reset button 8 and a toggle switch 9, the slider 4 has a fixing screw 20, the slider 4 is integrated with the rack of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com