Improved labyrinth type air intake chamber structure

An air inlet chamber and labyrinth technology, applied in the field of the improved labyrinth air inlet chamber structure, can solve the problems of unqualified glass fiber reinforced plastic, easy to block pipes, unstable wind pressure in the fan room, etc., to achieve effective filtration and ensure normal operation. , the effect of stable wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

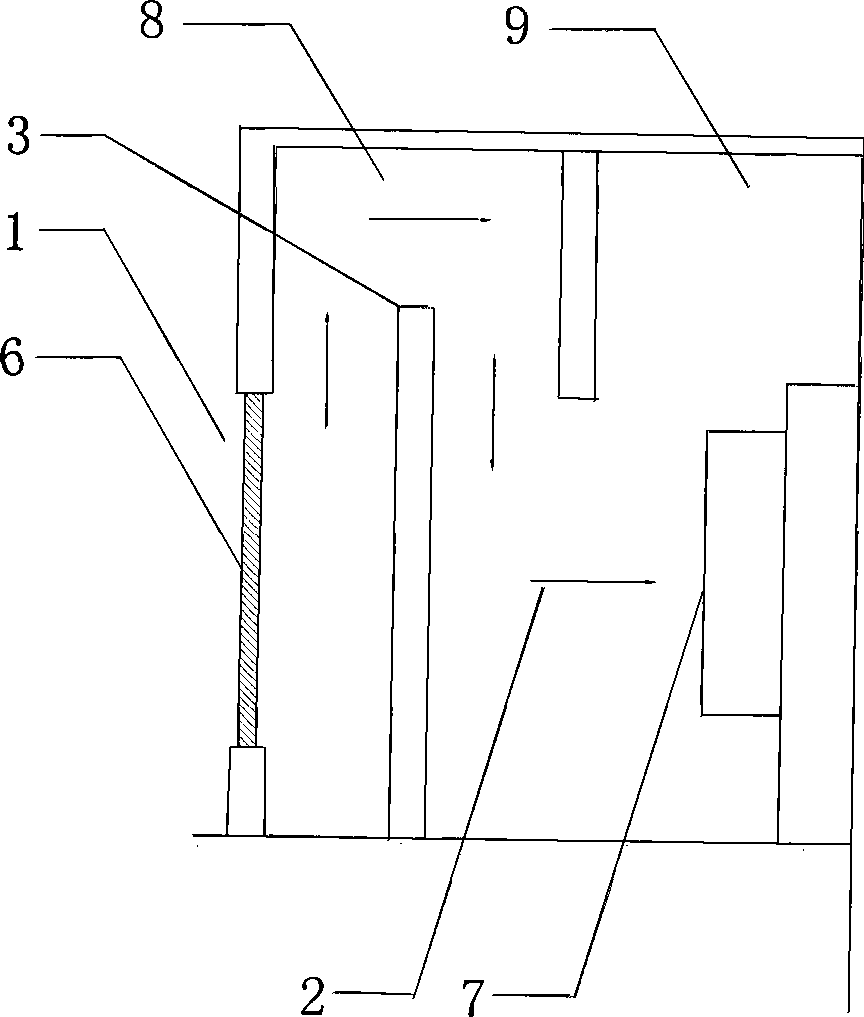

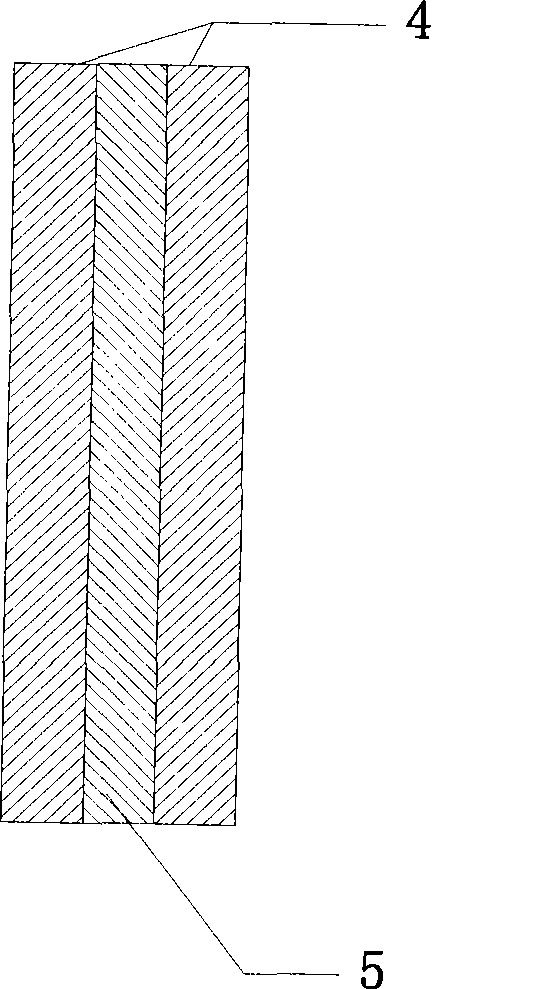

[0009] See figure 1 , figure 2 , a labyrinth-type air inlet chamber structure which includes an air inlet 1 and an air outlet 2, a filter screen 6 is installed on the air inlet 1, the air inlet 1 is facing the air outlet 2, and the air outlet 2 is facing the fan in the fan room The air suction port 7 is provided with a windshield wall 3 between the air inlet 1 and the air outlet 2, and the height of the windshield wall 3 is higher than that of the air inlet 1; Complete, fill the sound insulation cotton 5 between the double-layer hollow bricks 4.

[0010] When the fan is working, the wind enters from the air inlet 1, moves upward along the windshield wall 3, then moves horizontally to the right along the ceiling, then moves downward along the partition between the air inlet chamber 8 and the fan chamber 9, and finally is drawn by the air inlet of the fan. Inhalation, the entire air stroke is in the shape of a "several". After the air enters from the air inlet, the windshiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com