System and method for electronic type automatic latitude seeking

An electronic and automatic technology, which is applied in the field of weft-seeking system, can solve the problems of high quality requirements, long time consumption, and high product defective rate, etc., and achieve the effects of reducing labor intensity and quality requirements, improving product quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

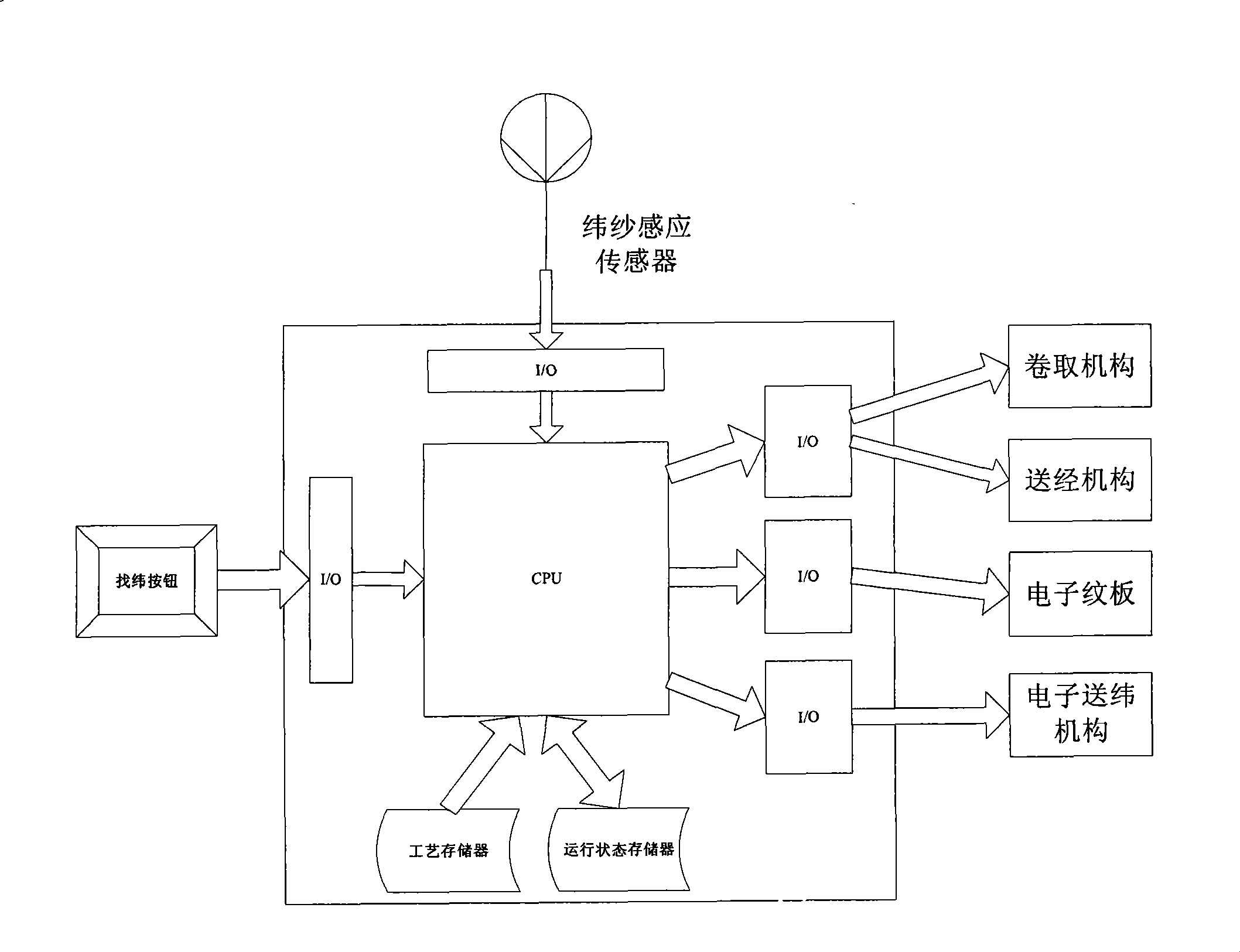

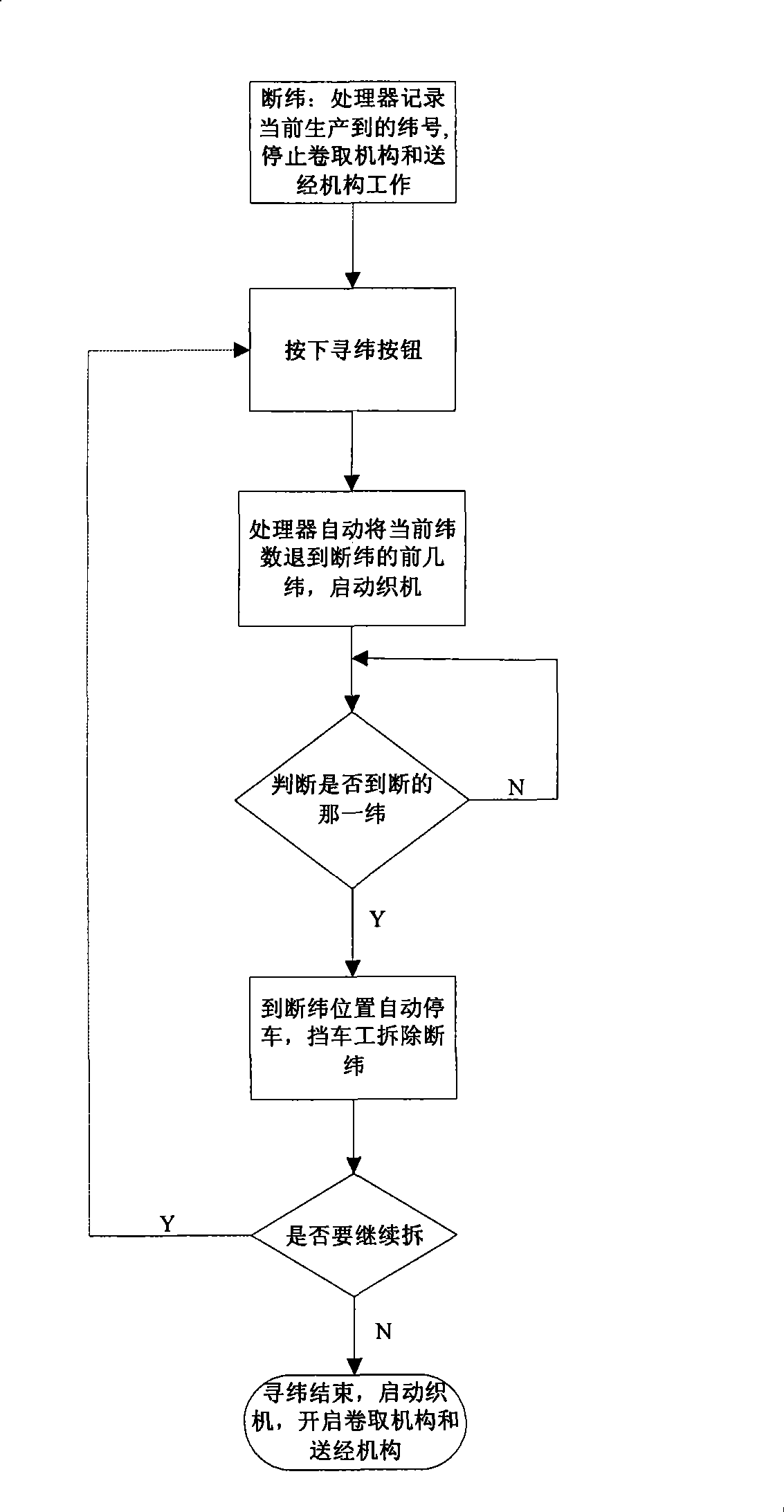

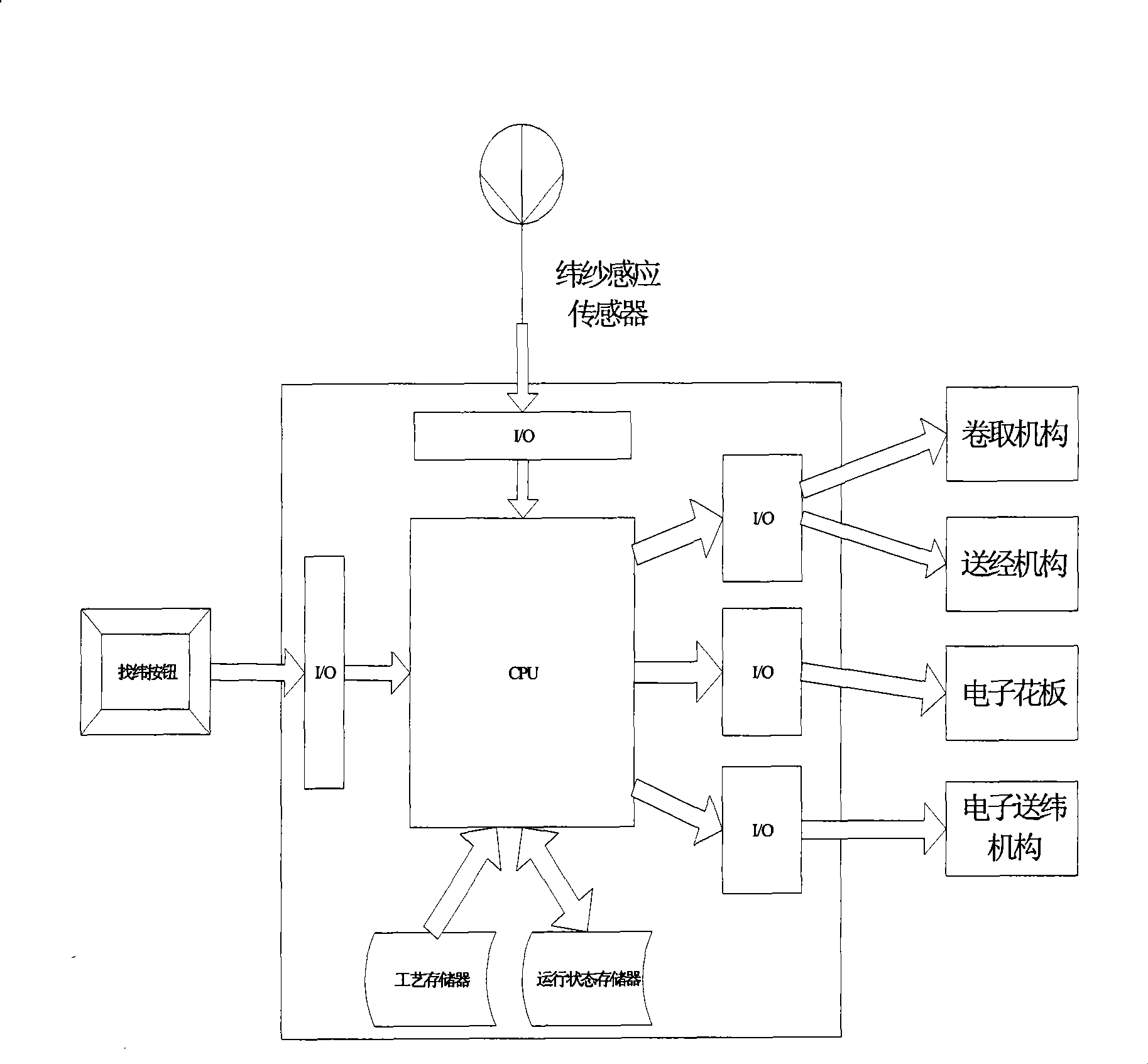

[0020] figure 1 is an automatic weft-seeking system according to the first embodiment of the present invention. The automatic weft-seeking system can be applied to dobby rapier looms.

[0021] The automatic weft-seeking system includes a central processing unit CPU, a process memory and an operating state memory, a weft yarn induction sensor, a take-up mechanism, a warp let-off mechanism, an electronic cardboard and an electronic weft feeding mechanism.

[0022] The weft induction sensor is used to detect the feeding status of the weft, if the weft is broken, the sensor will generate a broken weft signal.

[0023] Various process parameters are stored in the process memory, including coil stop signal, stop feed signal, electronic pattern data and weft selection signal, etc. The running state memory stores the running state data during the running process of the loom, such as the current weft number.

[0024] During the weaving process, the warp let-off mechanism is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com