Rail noise controller

A controller and noise technology, applied in tracks, roads, buildings, etc., can solve the problems of difficult replacement of intermediate layer damping materials, insufficient vibration and noise reduction effects, etc., and achieve the effects of low cost, convenient installation, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

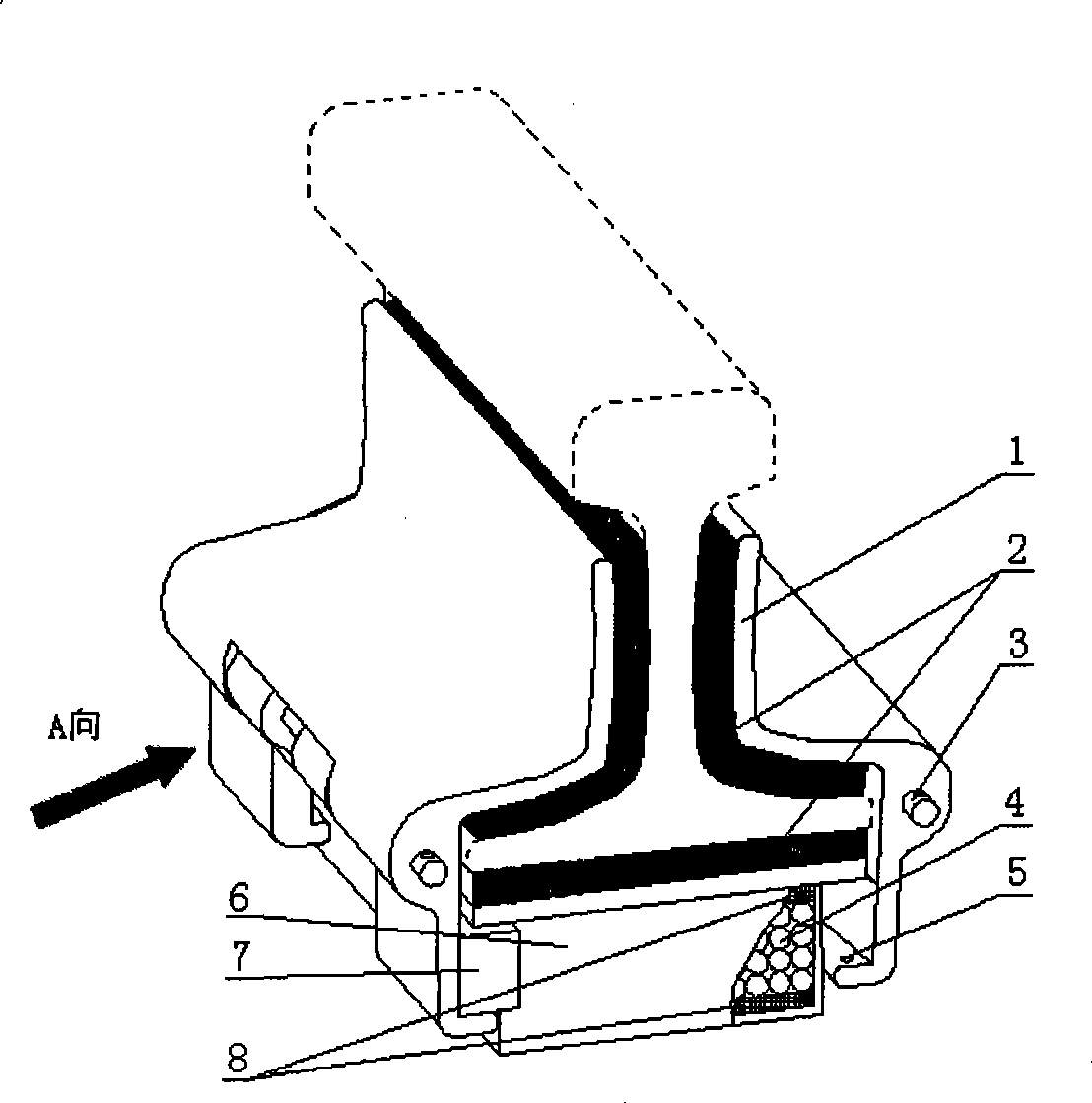

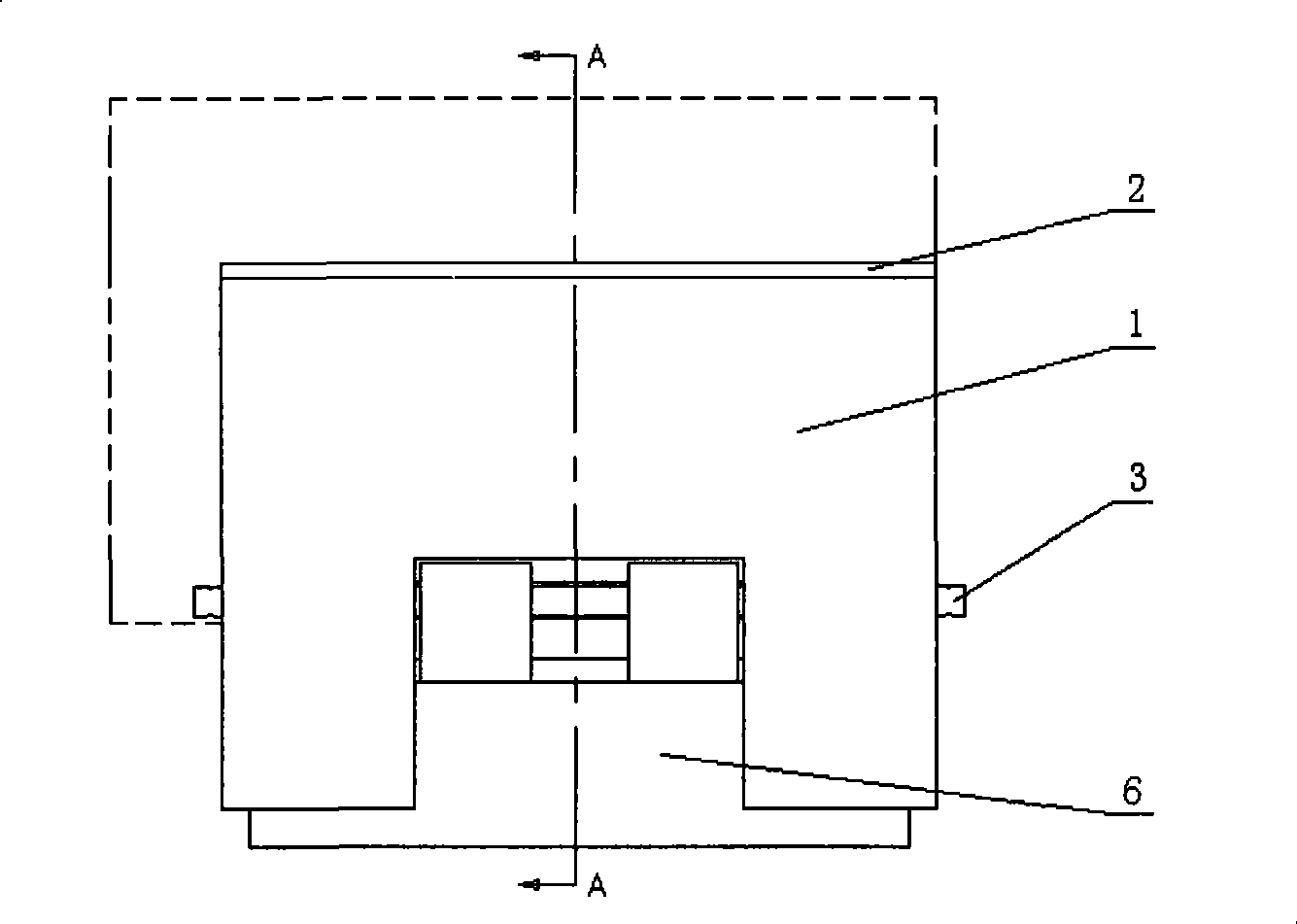

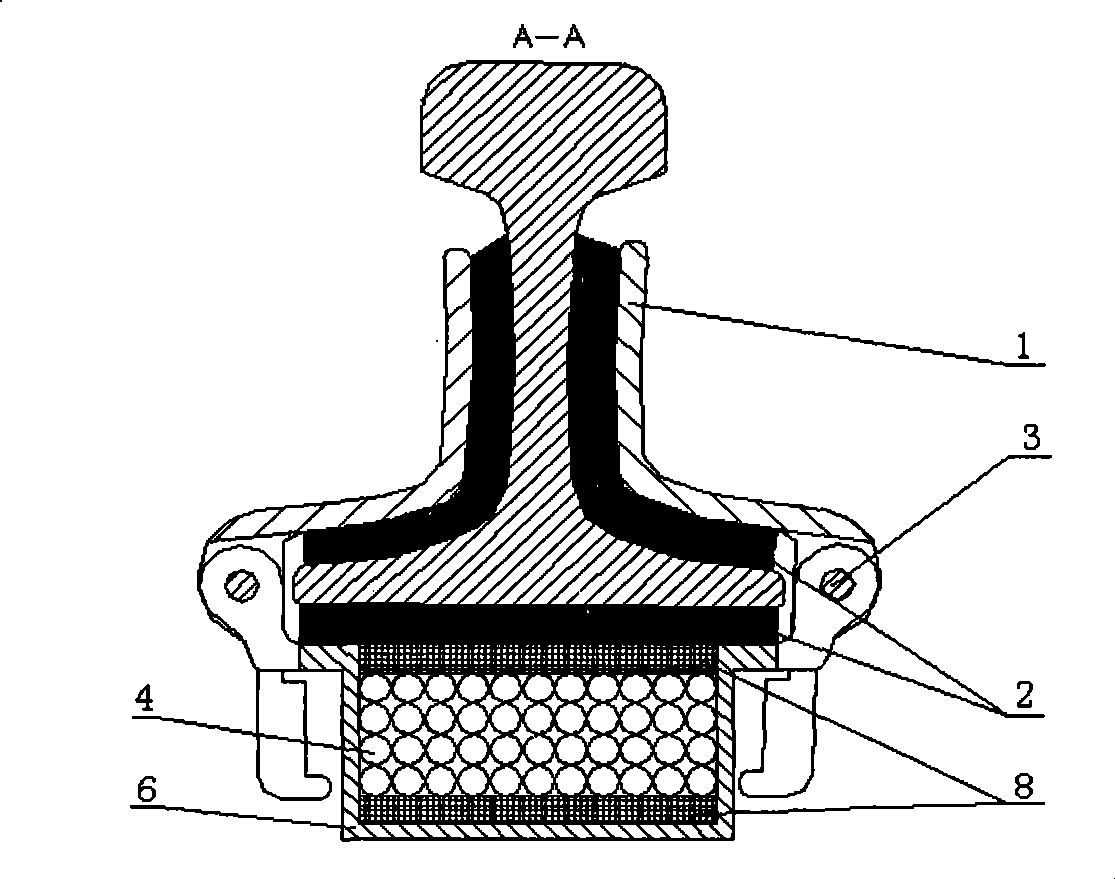

[0016] Such as figure 1 As shown, the damping layer 2 is respectively covered on the two side surfaces of the rail waist and the rail wing and the bottom surface of the rail. The damping layer 2 is made of high damping rubber. The damping layer 2 on the two sides of the rail waist and the rail wing The constrained layer member 1 is covered on the top, and the lower part of the constrained layer member 1 has two pin holes, and the upper side of the dynamic vibration absorber housing 6 has two pin holes, and the pin shaft 3 passes through the pin shaft holes to connect the constrained layer member 1 It is connected with the dynamic shock absorber shell 6. The clamping force between the constrained layer member 1 and the dynamic vibration absorber and the rail surface is implemented through the wedge block 7. The end of the curved lower arm of the constrained layer membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com