Trash remover

A cleaning machine and rotating shaft technology, applied in the field of cleaning machines, can solve problems such as difficulty in picking up floating objects, large outward force of dirt, and difficult operation, etc., and achieve the effect of simple structure, low power consumption, and convenient fishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

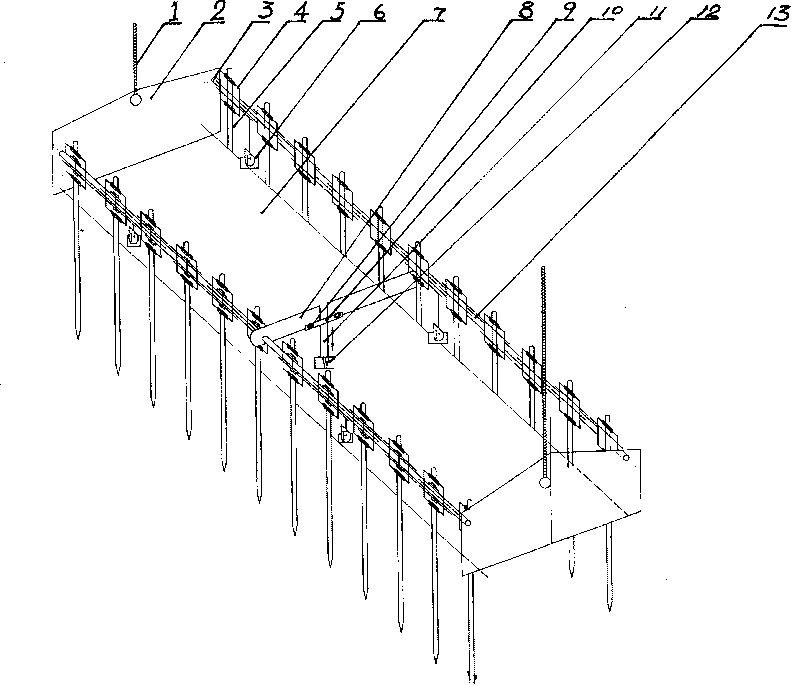

[0014] Example 1, such as figure 1 , 3 As shown, the present invention includes: hoisting equipment, a facility bearing platform 7, an end plate 2, a rotating shaft 13, grid bars 5, power and a rotating device connected to each other by a steel wire rope 1 and a lifting device, and its specific structure is that the bearing platform 7 is composed of two beams It is fixedly connected with the upper bearing plate, the two ends of the beam are connected with the lower parts of the two end plates 2 by bolts or welded, and the upper sides of the two end plates are provided with shaft holes 3 respectively socketed with the ends of the two shafts 13, and the shaft body The upper and lower sides are arc-shaped, the middle part is flat, and the shaft end is circular. The rotating shaft is socketed with the tapered grid bar through the bearing seat on the grid bar hole. The gear 23 and the motor 6 fixed to the rotating shaft are fixedly connected to the grid bar. The gears are connecte...

Embodiment 2

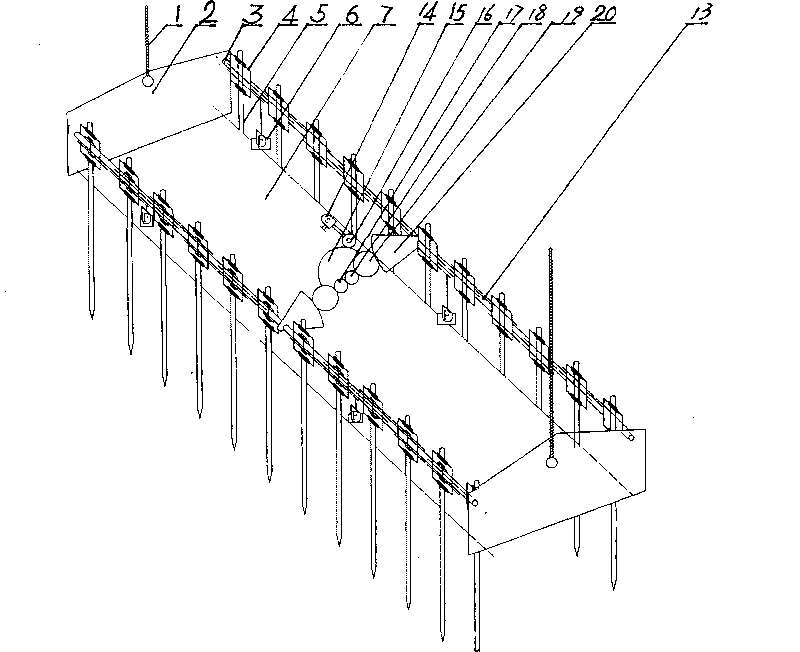

[0015] Example 2, such as figure 2 , 3 As shown, the present invention includes: hoisting equipment, a facility bearing platform 7, an end plate 2, a rotating shaft 13, grid bars 5, power and a rotating device connected to each other by a steel wire rope 1 and a lifting device, and its specific structure is that the bearing platform 7 is composed of two beams It is fixedly connected with the upper bearing plate, the ends of the two beams and the lower parts of the two end plates 2 are connected by bolts or welded, and the upper sides of the two end plates are provided with shaft holes 3 respectively socketed with the ends of the two shafts 13, and the shaft body The upper and lower sides are arc-shaped, the middle part is flat, and the shaft end is circular. The rotating shaft is connected to the tapered grid bar through the grid bar seat 4. The said bar bar seat is two U-shaped with through holes and the backs are fixed. Frame constitutes, and one side U-shaped frame is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com