Flexible Rod Based Anti-Stage Tool

A flexible rod and tool technology, used in drill rods, drilling equipment, earth-moving drilling, etc., can solve problems such as bit collapse, damage to downhole drilling tool assemblies, reduction of drilling efficiency, etc., to reduce axial vibration and torsional vibration, The effect of reducing the number of trips and shortening the drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

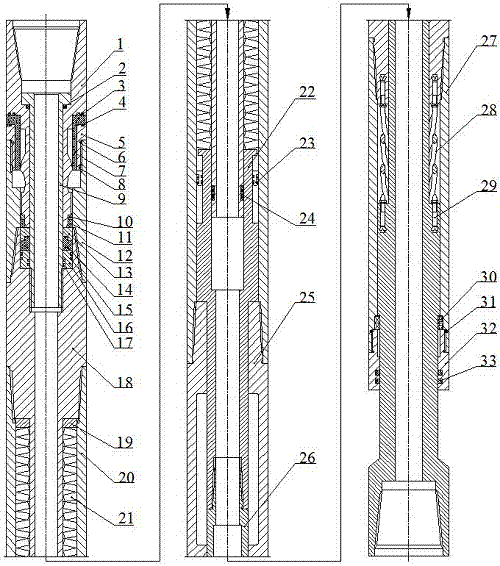

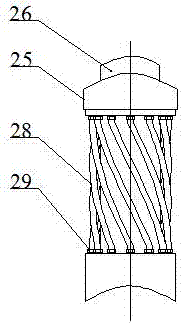

[0011] According to the drawings, the anti-sluggish tool based on the flexible rod is mainly composed of a vibration damping assembly, an adjustment washer 19, an upper housing 20, a combined disc spring 21, an anti-drop tube 22, a floating sealing ring 23, and a dynamic sealing ring. 24. The middle shell 25, the central tube 26, the lower shell 27, the flexible rod 28, the expansion bolt 29, the self-aligning bearing assembly 30, the O-shaped sealing ring b31, the locking joint 32, and the rectangular sealing ring f33; it is characterized in that , the vibration damping assembly includes upper joint 1, rectangular sealing ring a2, rectangular sealing ring b3, rectangular sealing ring c4, locking joint 5, O-shaped sealing ring a6, upper vibration-absorbing ring 7, upper locking ring 8, anti-falling center Tube 9, washer 10, middle vibration-absorbing ring 11, spline joint 12, lower locking ring 13, lower vibration-absorbing ring 14, rectangular sealing ring d15, sealing ring 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com