Impeller structure of ventilator

A technology of blower and impeller, applied in the field of impeller structure of blower, can solve the problems of increasing installation cost, time, money waste, and long time for re-installation and calibration, and achieves the best stability and avoids shaking or noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

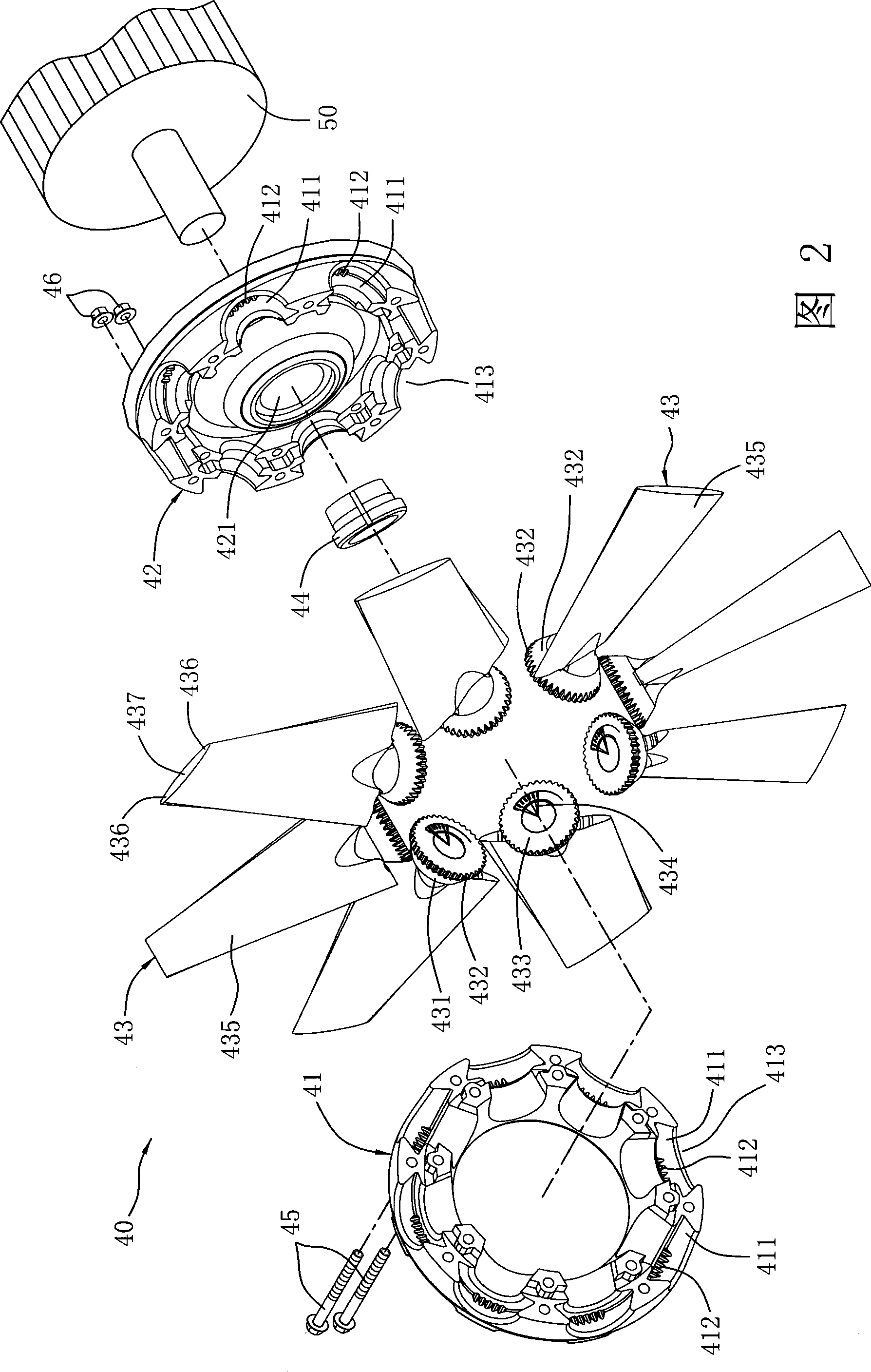

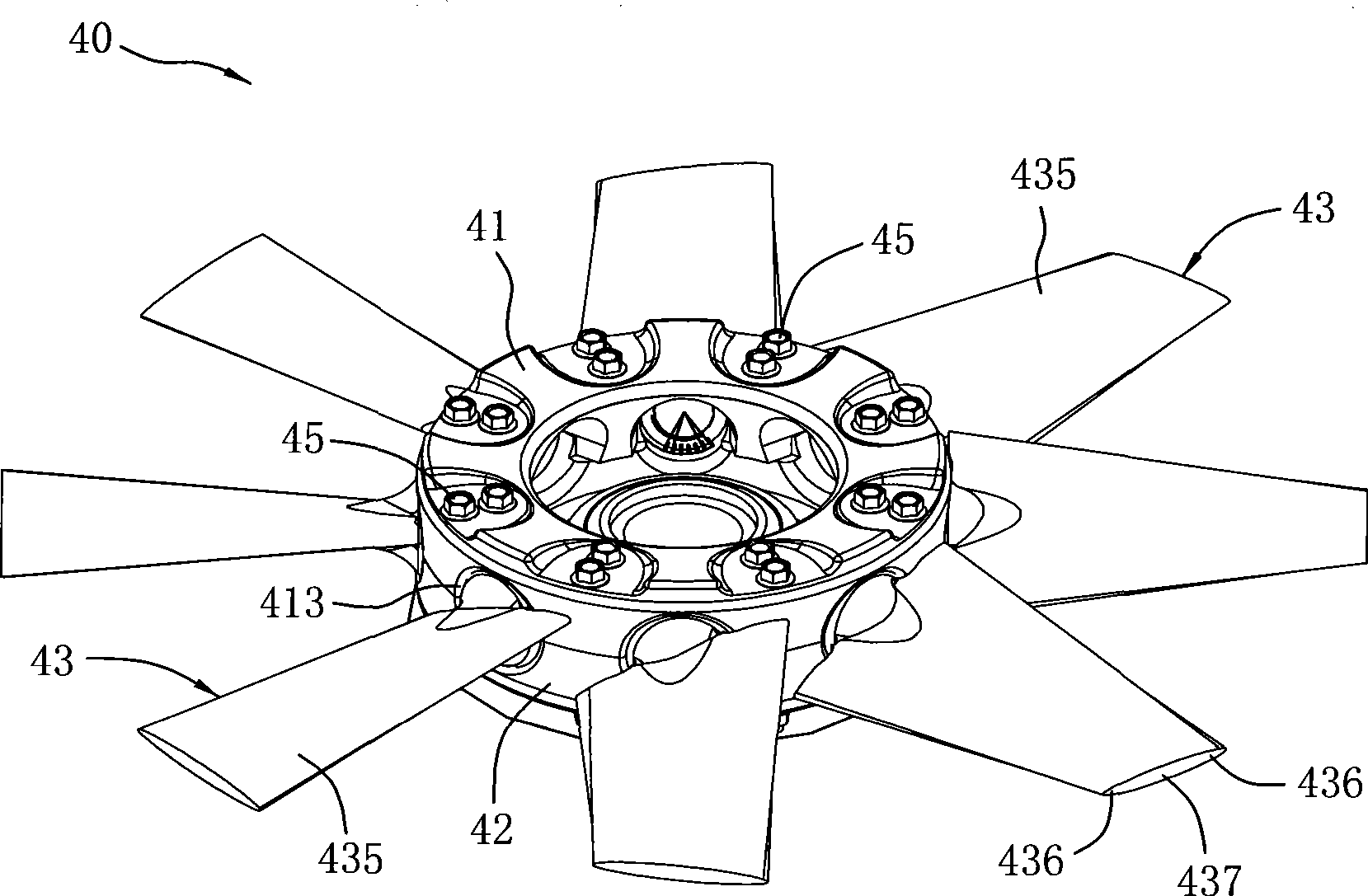

[0013] In order to make the present invention clear and detailed, the preferred embodiments are enumerated hereby in conjunction with the following illustrations, and the structure and technical characteristics of the present invention are described in detail as follows:

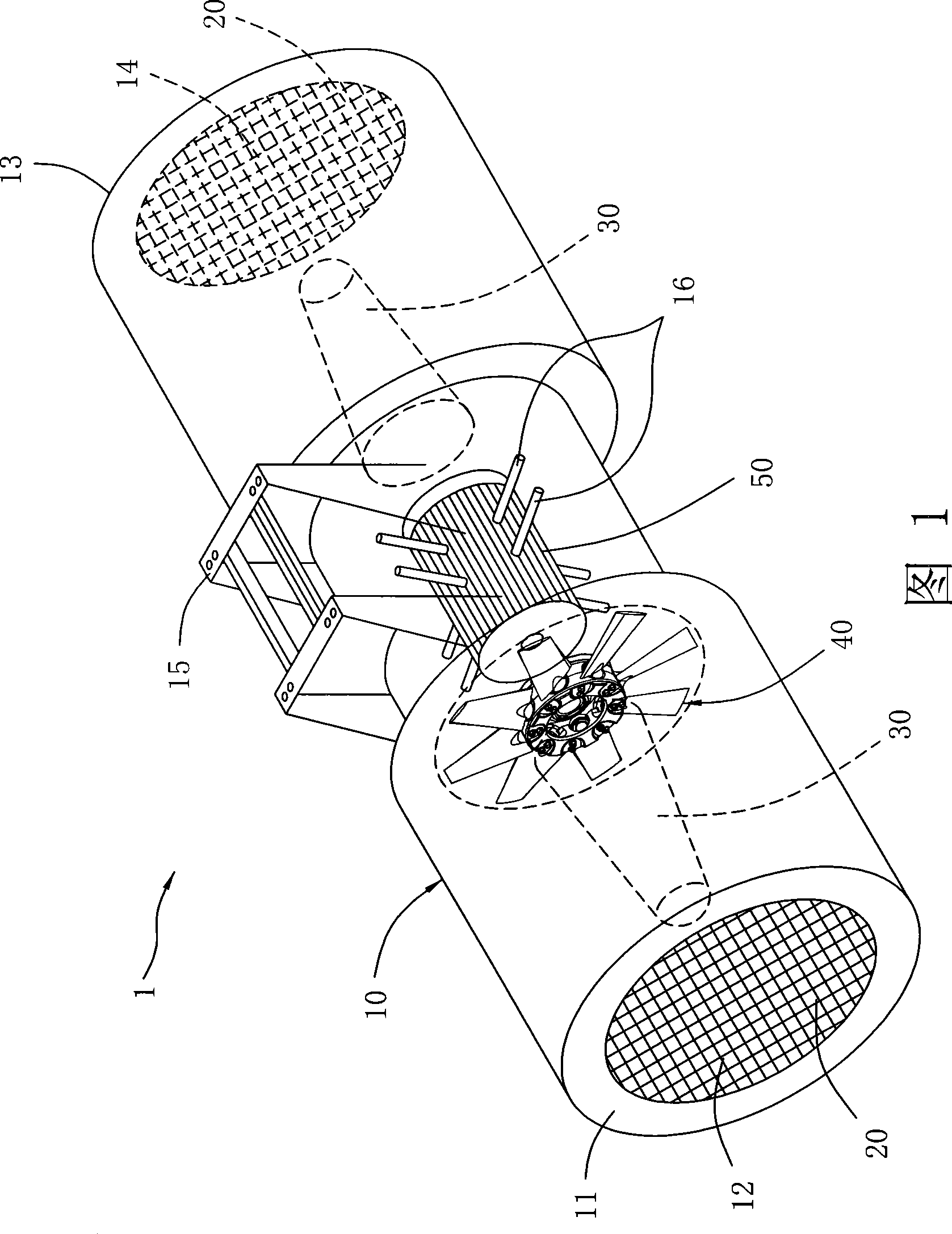

[0014] Please refer to Figure 1 to Figure 4 As shown, the air blower 1 of the present invention includes a cylindrical outer box 10. The outer box 10 is a double-layer shell structure with inner and outer layers, and can use galvanized steel plate and galvanized punched steel plate or the like It is made of board, and the sound-absorbing material can be filled between the outer layer and the inner layer. The sound-absorbing material can be made of cotton material; An air outlet 14 is arranged on the top; in addition, at least one above bracket 15 can be arranged at an appropriate place outside the outer box 10, so that the air blower 1 can be suspended for use through the bracket 15, such as suspended on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com