Heat radiating device for LED vehicle lamp

A technology of LED lights and heat sinks, applied in vehicle interior lighting devices, signal devices, lighting devices, etc., can solve the problems of high power consumption, high heat energy, reduced light output, damage, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Regarding the technical means of the present invention, the preferred embodiments of the present invention will be described in detail below in conjunction with the drawings:

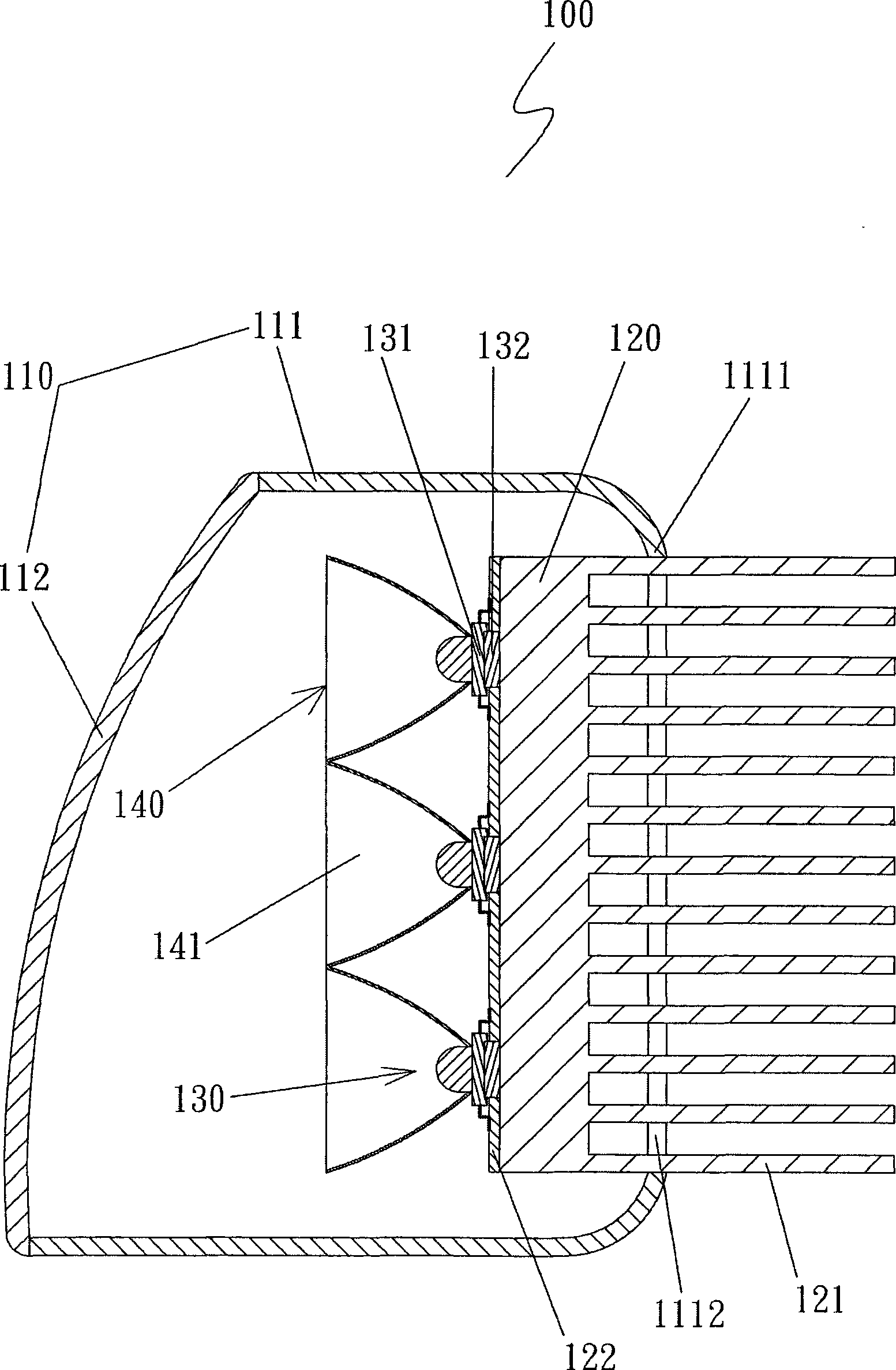

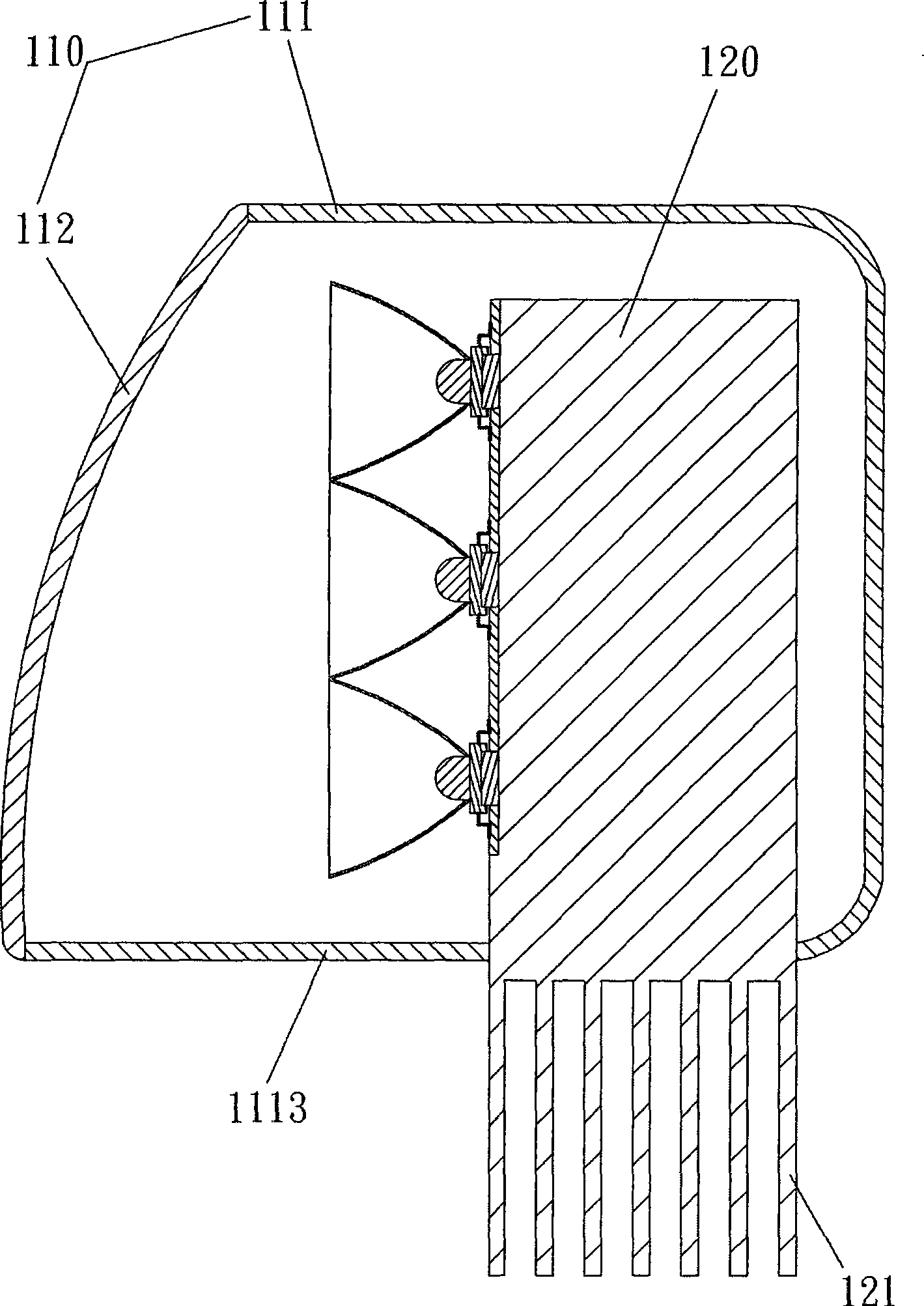

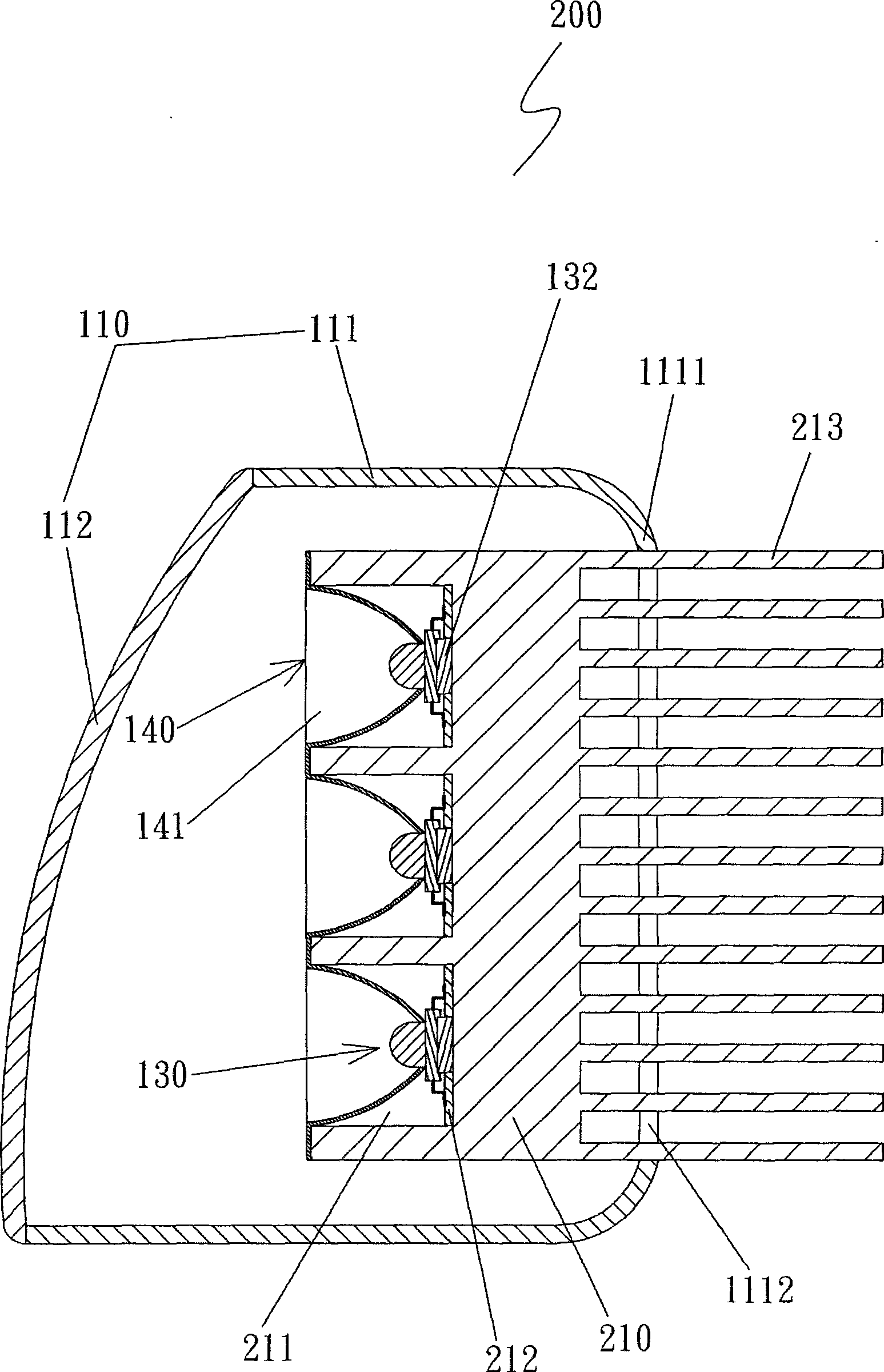

[0056] First, see figure 1 As shown, it is a combined cross-sectional schematic diagram of the first embodiment of the heat dissipation device for LED lamps of the present invention. In this example, the LED car light 100 includes a car light group 110, a heat dissipation module 120, several LEDs 130, a circuit unit, and a reflection unit 140, wherein:

[0057] The car light group 110 is fixed on the vehicle body, and the car light group 110 includes a base 111 and a lamp housing 112. The lamp housing 112 is a light-transmitting body and is fixed on the The front of the base 111 and the rear side 1111 of the base 111 are provided with a perforation 1112 for the heat dissipation module 120 to pass through;

[0058] The heat dissipation module 120 is made of metal material, ceramics or other mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com