Practical three-folding optical cavity apparatus of transverse flow CO2 laser

A laser and optical cavity technology, applied in the field of lasers, can solve the problems of the adjustment of the optical axis position of the resonator cavity, the difficulty of adjusting the multi-mirror cavity, the difficulty of designing, manufacturing, and adjusting the actual use, and the complexity of the structure of the multi-refractive optical resonator. Effective absorption, prevention of parasitic oscillation, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

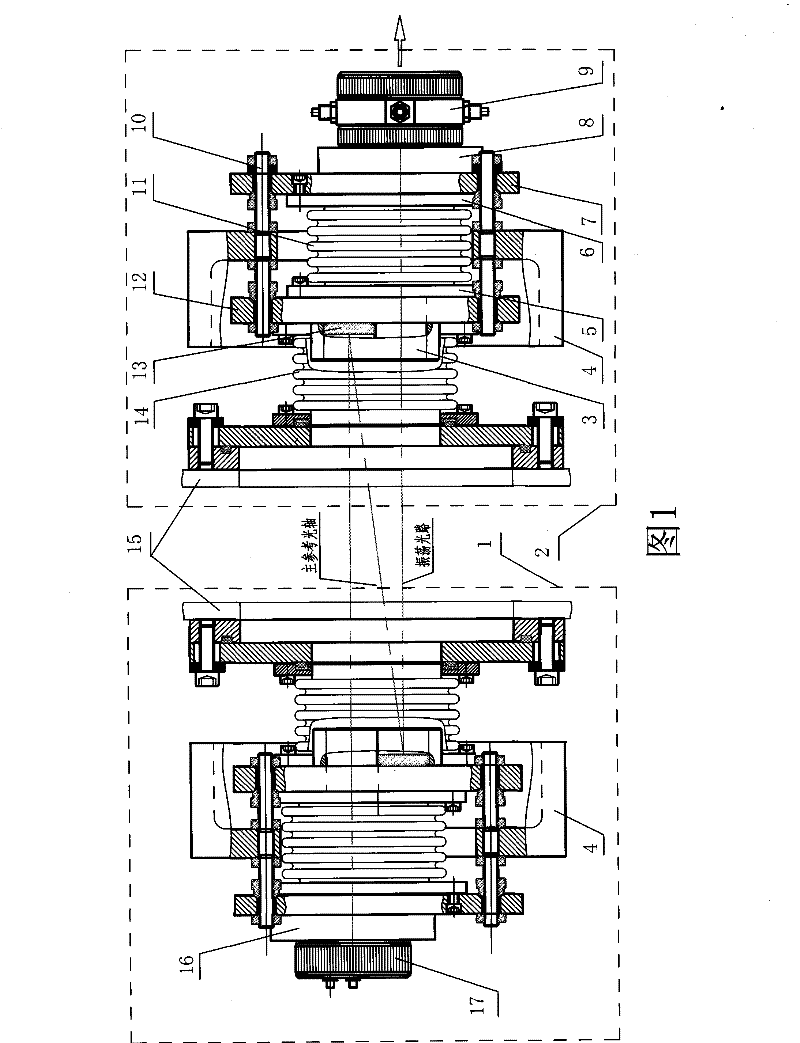

[0050] cross flow CO 2 The practical three-fold optical cavity device of the laser is composed of the front optical cavity 2 and the rear optical cavity 1 with the same structure and the adjustment mechanism of the window mirror seat and the rear mirror seat. The front optical cavity 2 and the rear optical cavity 1 include folding mirrors With integrated adjustment mechanism, non-coaxial double bellows mechanism, optical cavity mechanical positioning and cavity mirror adjustment mechanism, and optical cavity external cold water circulation mechanism.

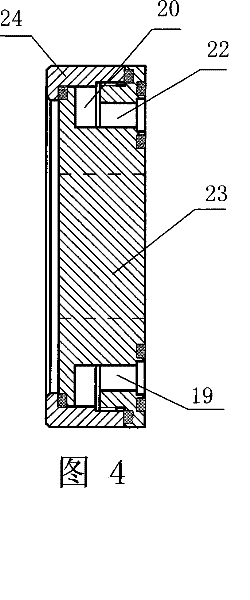

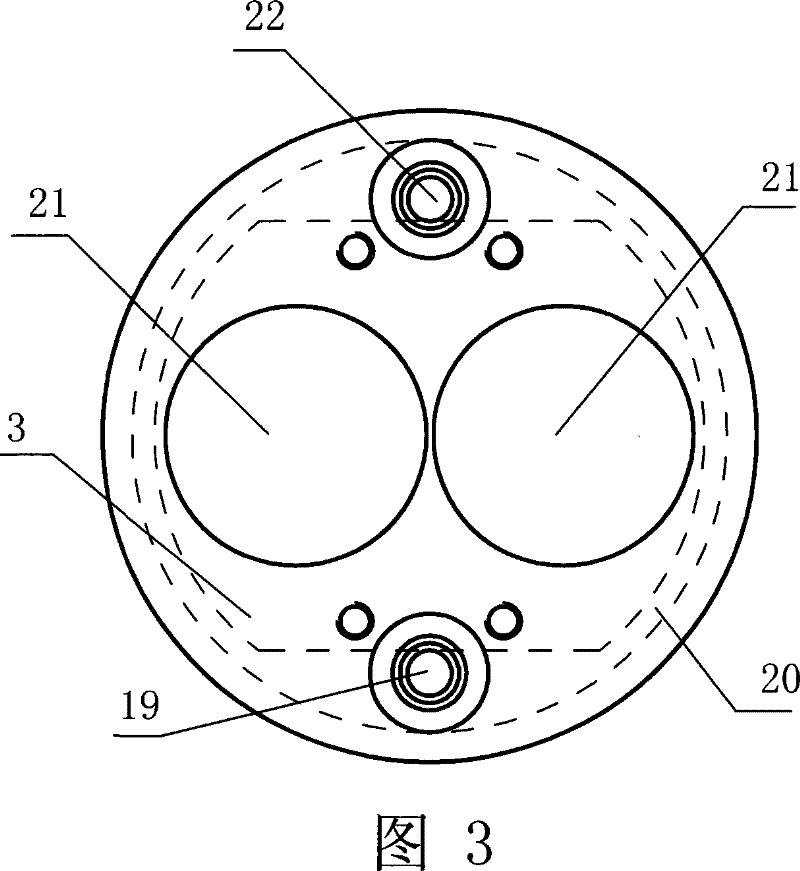

[0051] Folding mirror and integrated adjustment mechanism, including direct cooling copper folding mirror 13, absorbing cold diaphragm 3, and intermediate integrated flange 12; Figure 1-4 with Figure 6-9 As shown, a light transmission hole 36 and a folding mirror mounting hole seat 29 are respectively arranged on both sides of the center of the circle of the middle integral flange 12, and the two sides of the connecting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com