Band sawing machine with rotating angle

A technology of turning angle, band sawing machine, applied in sawing machine device, metal sawing equipment, clamping and other directions, to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

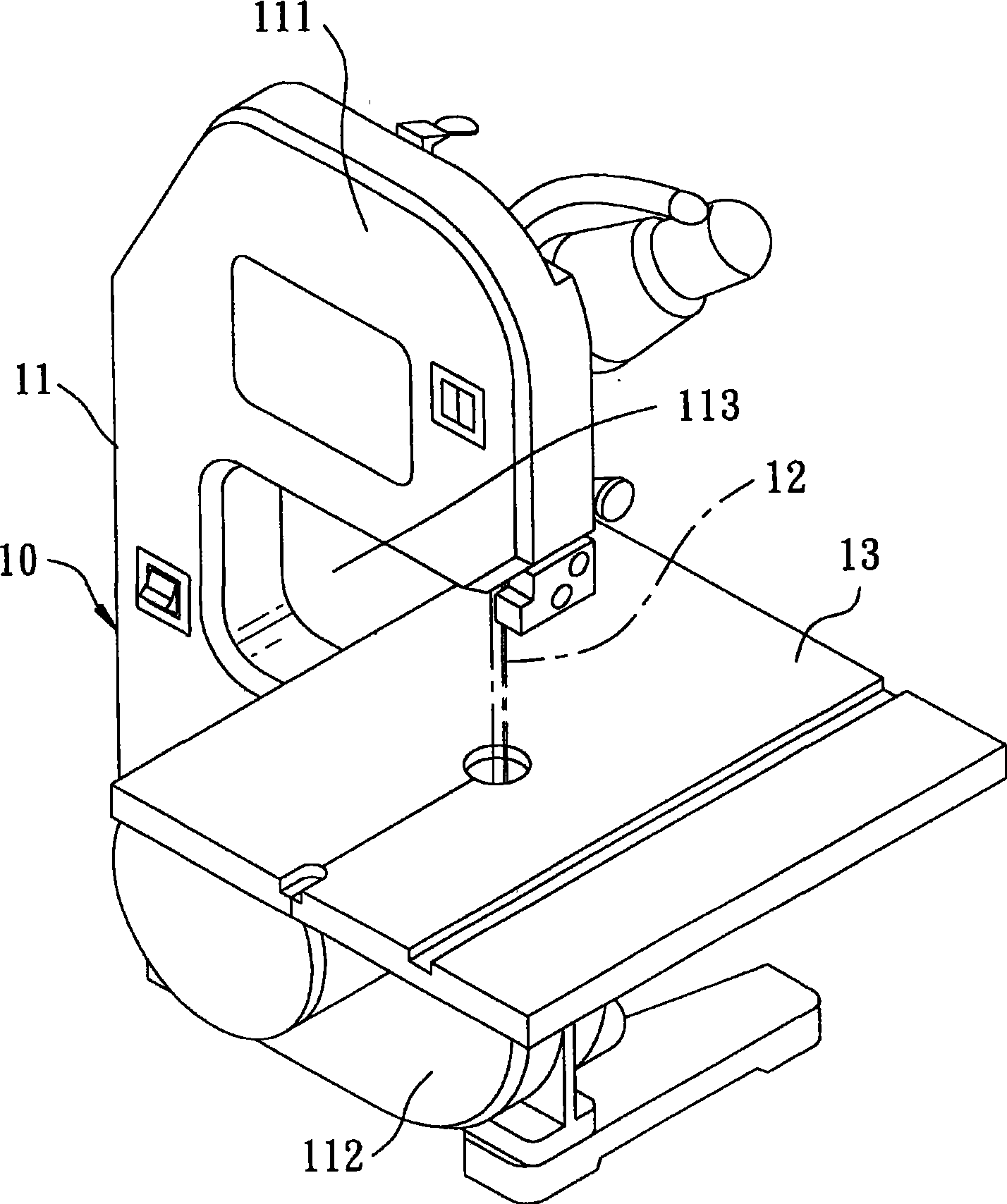

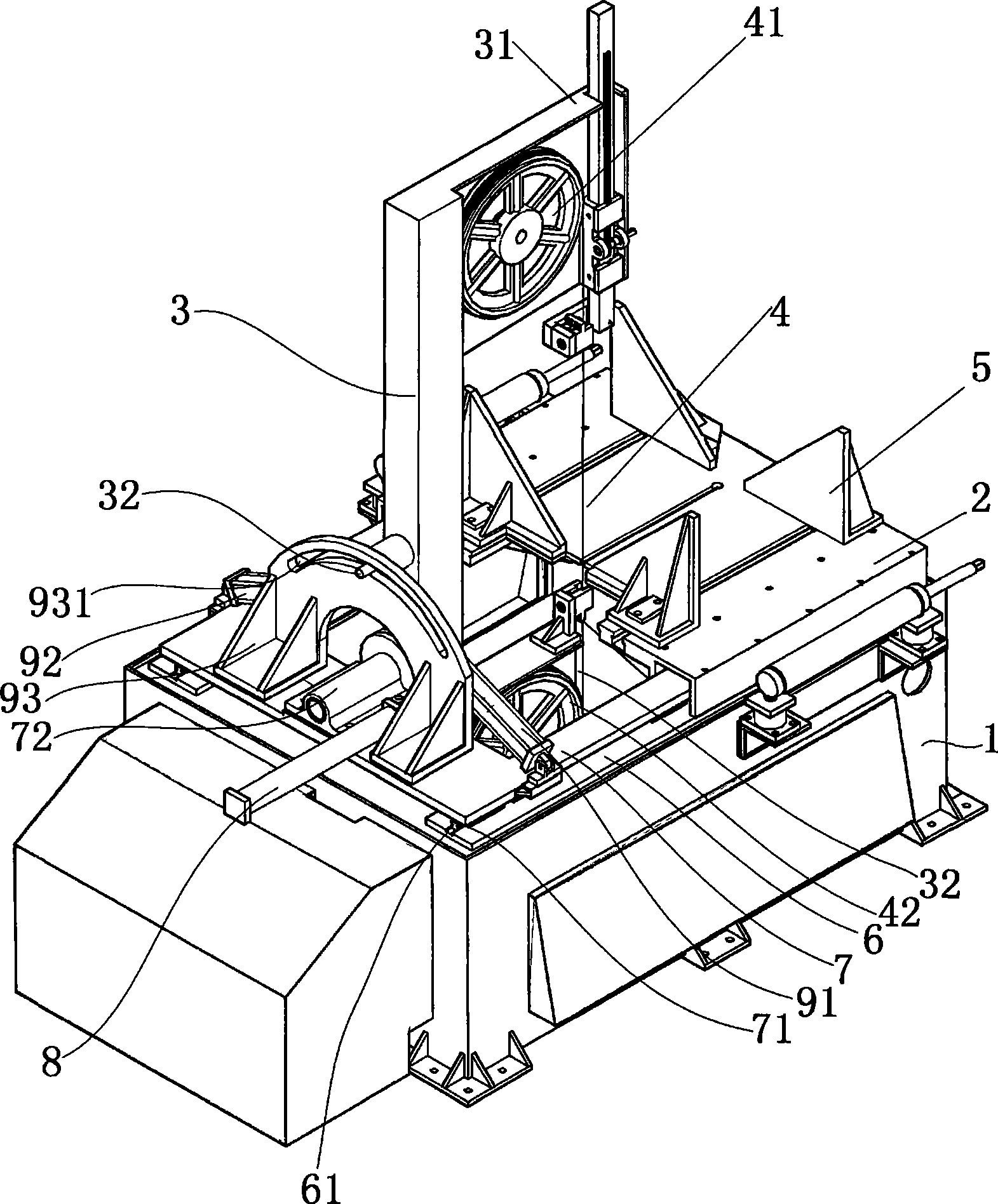

[0024] see image 3 , Rotary angle band sawing machine, including bed 1, saw table 2, saw bow 3 and band saw 4, saw bow 3 has opposite upper end 31 and lower end 32, upper and lower ends 31, 32 are installed with belt The rotary parts 41 and 42 of the saw 4 revolve around the upper and lower ends of the saw bow 3. On the saw table 2, there is a belt opening 14 for the saw band 4 to pass through. On the saw table 2, there are movable clamps 5 and 5 For clamping workpieces.

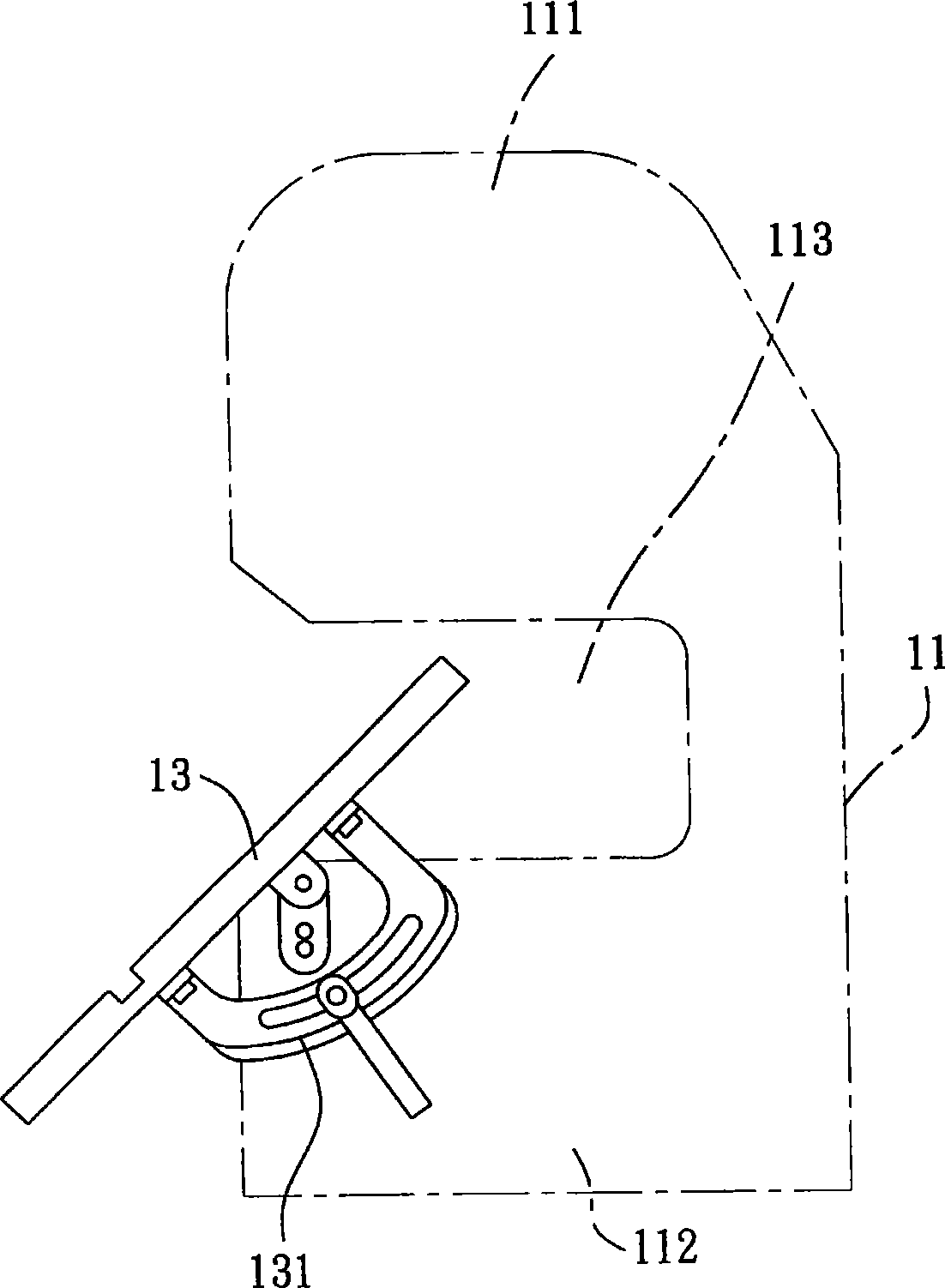

[0025] Guide rails 6 are fixedly installed on both sides of the bed 1 , and slide grooves 61 are opened on the guide rails 6 . The swivel angle band sawing machine also includes a saw bow installation platform 7, the saw bow installation platform 7 is a "door"-shaped member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com