Electric tools

A technology of electric tools and bridge circuits, applied in the field of electric tools, can solve the problems of excessive locking current, power supply voltage drop, large starting current, etc., and achieve the effect of expanding the speed range and suppressing the voltage drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described below based on the drawings.

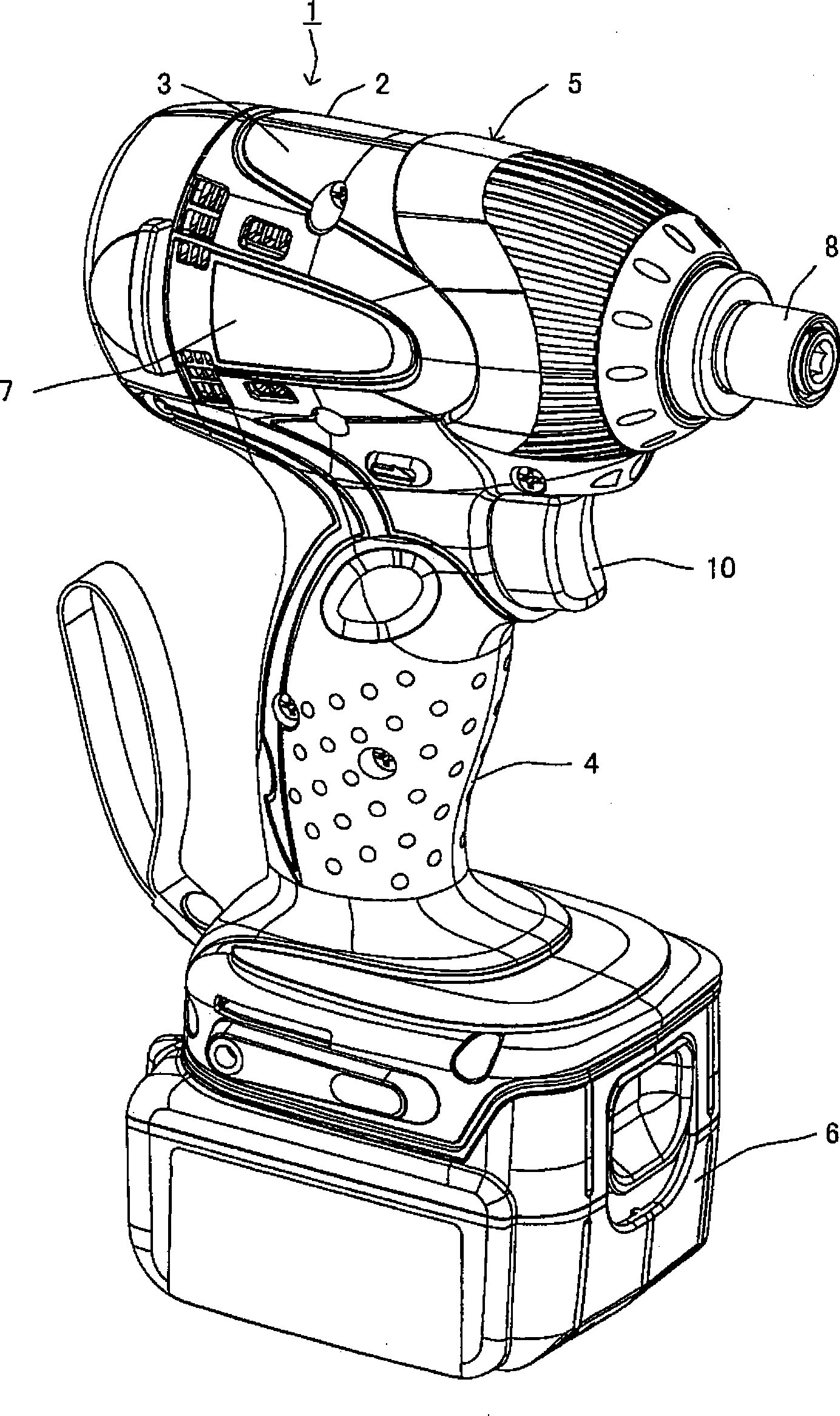

[0042] figure 1 It is a perspective view showing the appearance of the cordless impact driver 1 to which the embodiment of the present invention is applied.

[0043]The rechargeable impact driver 1 of this embodiment includes the following structure: a main body casing 5, which is assembled from the casings 2 and 3 divided in the left and right sides, and a handle part 4 is extended below; a battery pack 6, which is disassembled. It is freely attached to the lower end of the handle part 4 of the main body case 5 .

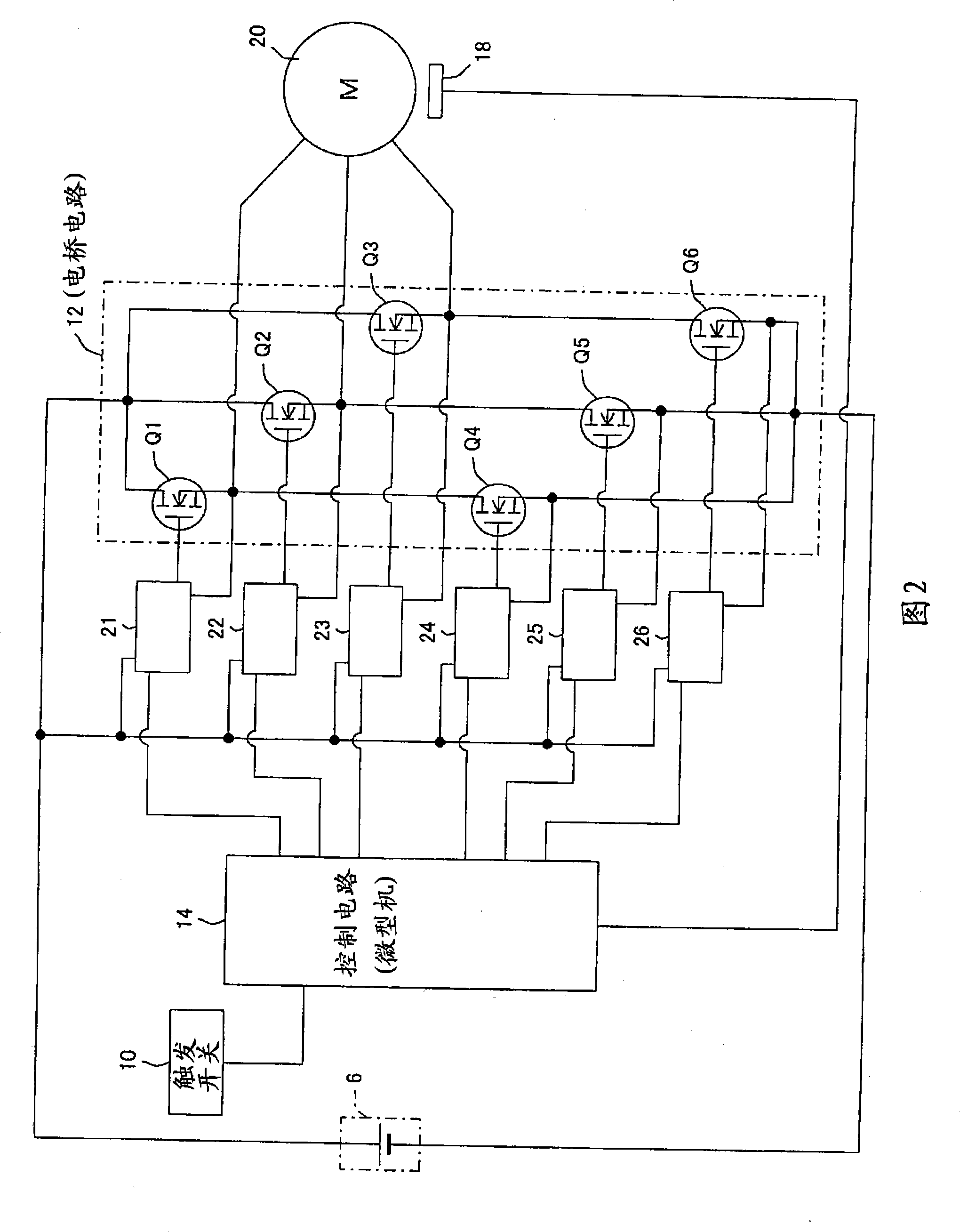

[0044] In addition, the rear of the main body casing 5 ( figure 1 on the left side of the cordless impact driver 1 is the motor housing part 7 that houses the DC motor 20 (see FIG. 2 ), which is the power source of the cordless impact driver 1, and the speed reduction mechanism is housed in the front of the motor housing part 7. and hitting mechanism.

[0045] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com