A controllable compensation type full torque energy-saving soft start device for asynchronous motors

A technology of asynchronous motor and soft start, which is applied to circuit devices, starters of single multi-phase induction motors, motor generators/starters, etc., and can solve grid voltage fluctuations, sensitive electrical equipment failure outages, and soft starter startups Slow and other problems, to achieve the effect of compensating grid voltage fluctuations, overcoming grid voltage fluctuations, suppressing and maintaining starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The invention proposes a new type of soft start device capable of full torque fast start and reactive power compensation, which will bring very important significance to the improvement of the existing asynchronous motor start technology.

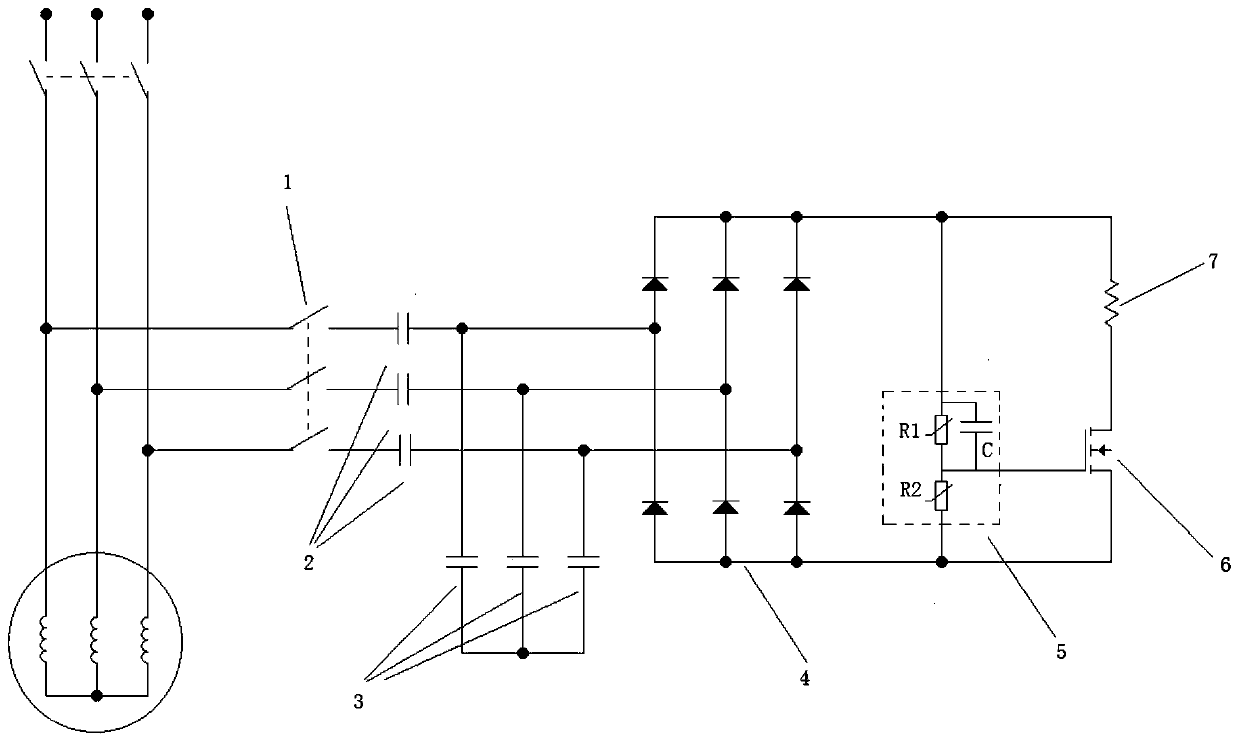

[0031] See attached figure 1 , an asynchronous motor controllable compensation type full torque energy-saving soft start device of the present invention includes an air switch 1, a three-phase start capacitor 2, a three-phase compensation capacitor 3, a three-phase rectifier bridge 4, a power transistor 6, a power resistor 7 and a control Circuit 5, air switch 1, three-phase starting capacitor 2 and three-phase compensation capacitor 3 are connected in parallel with the three-phase power input end of the controlled motor, and the AC input end of the three-phase rectifier bridge 4 is connected to the three-phase compensation capacitor 3 in parallel, the DC output terminal of the three-phase rectifier bridge 4, the collector and emitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com