Combined structure of electromagnetic switch and relay and start-stop motor using structure

An electromagnetic switch and relay technology, applied in the direction of structural connection, circuit, electrical components, etc., can solve the problem of increasing the short circuit between the connecting wire and the automobile engine, the difficulty of maintaining the connecting wire, and reducing the reliability and effect of the current limiting resistor to suppress the peak starting current of the motor. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

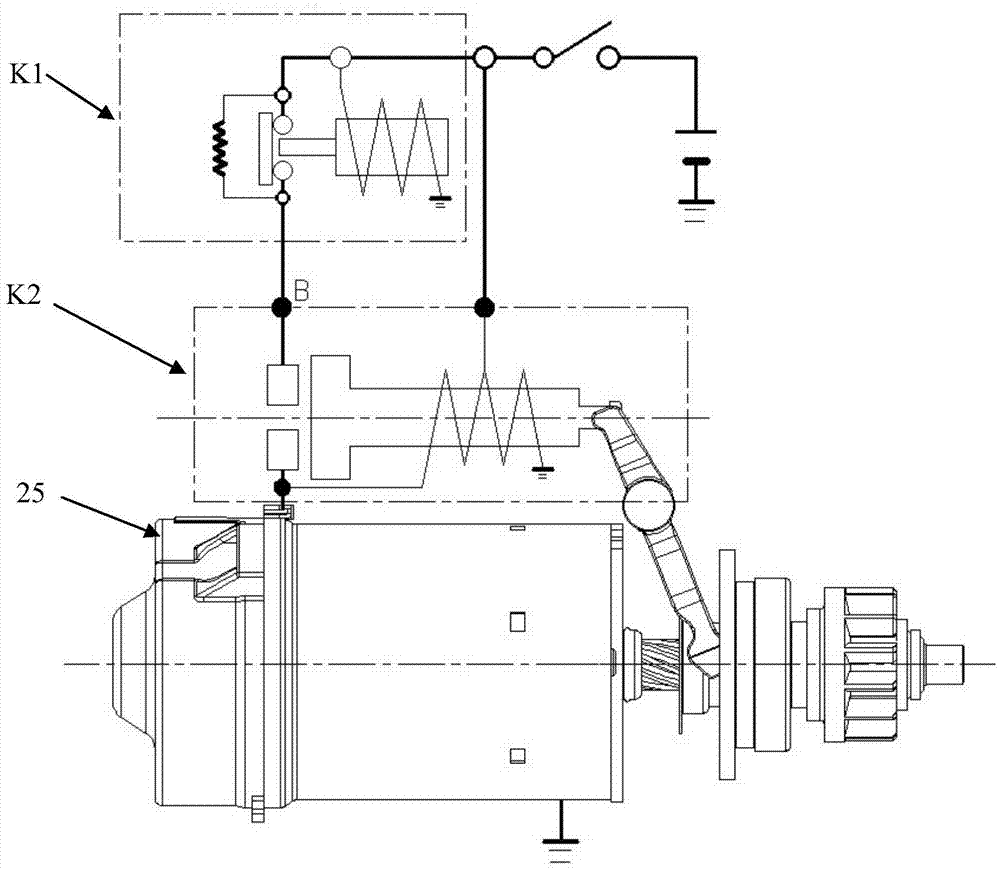

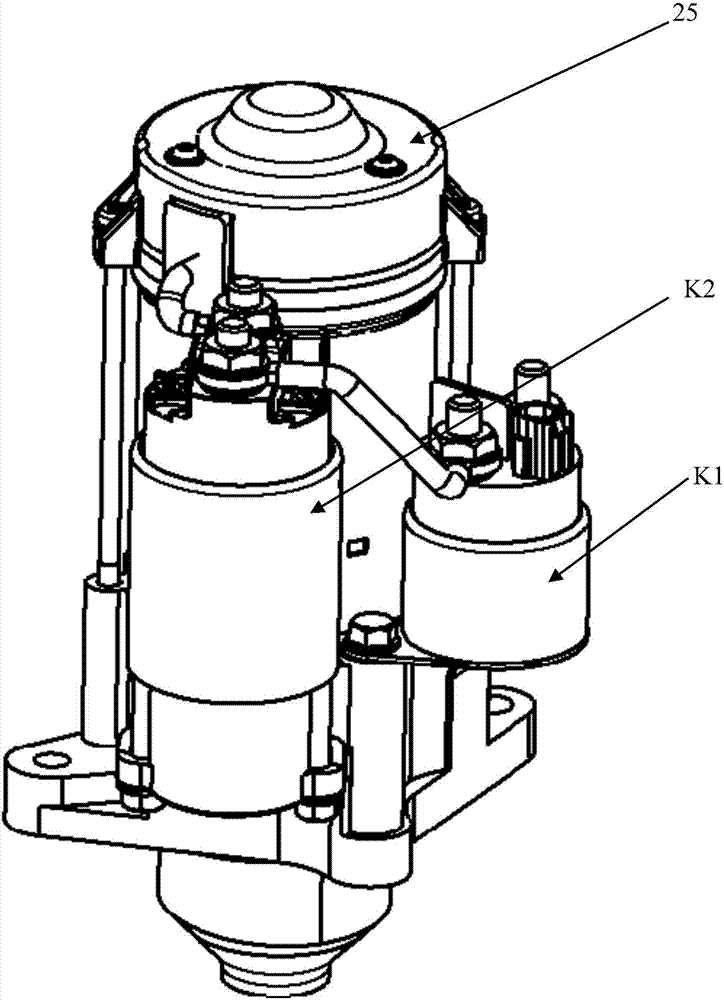

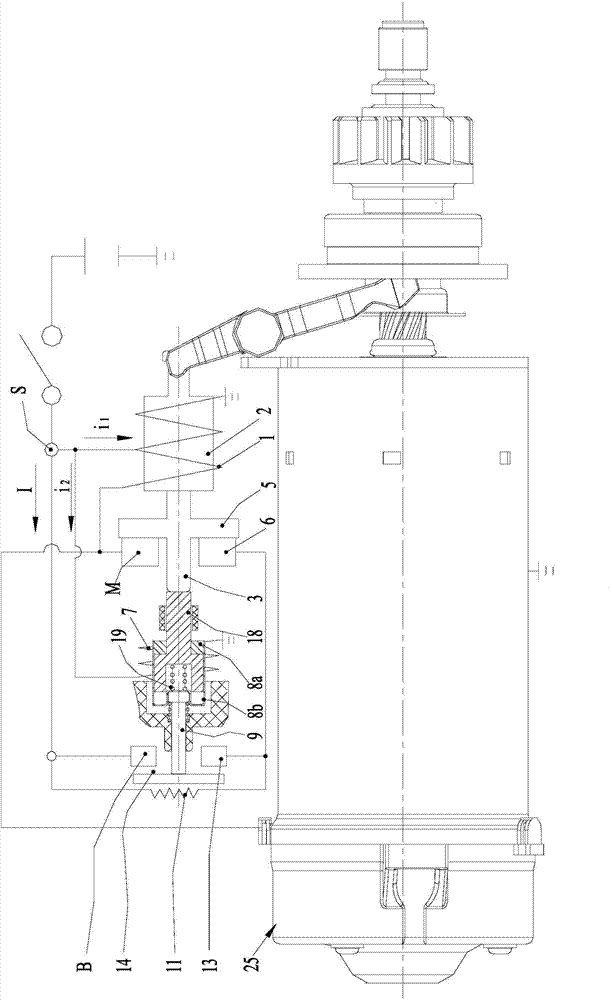

[0070] Such as Figure 4 to Figure 7-2 , Figure 11 to Figure 14 As shown, the integrated structure of the electromagnetic switch and relay in Embodiment 1 of the present invention includes a long cylindrical shell, an electromagnetic switch mechanism, a relay mechanism, a terminal block 26 , a controller 24 and a control terminal S. Wherein, the electromagnetic switch mechanism is installed in the bottom of the long shell, and the relay mechanism is positioned at the top of the electromagnetic switch mechanism in the long shell, that is, in the middle of the long shell, and the two are positioned at intervals by the terminal block 26; the long shell is composed of a cover body 22, a shell body 16 and inner housing 23; the electromagnetic switch mechanism includes a switch action assembly composed of switch winding 1, switch core 2, switch push rod 3, switch spring 4, switch dynamic and static contacts 5, 20 and output terminal M The relay mechanism includes a relay action as...

Embodiment 2

[0085] Such as Figure 4 , Figure 8-1 to Figure 14 As shown, the combined structure of the electromagnetic switch and the relay of the second embodiment of the present invention and the first embodiment and the start-stop motor applying the structure are basically the same, and their difference is that the rod head 18a of the connecting rod 18 of the second embodiment is " T" shape, the iron core end cover 8b is a bottom open cover body with an inner cavity adapted to the rod head 18a, and the cover body is composed of an upper part made of a magnetically permeable material and a lower part made of a non-magnetically permeable material. , the outer surface of the cover is covered with a thin layer of non-magnetic material, and the relay iron core 8a is fixedly connected to the bottom opening of the iron core end cover 8b. In addition, in the second embodiment, the I-shaped rubber pad 19b is used to replace the connecting rod spring 19 in the first embodiment. The working pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com