Cart for storing tire second stage building tire blank

A technology for storing vehicles and green tires, which is applied in the field of storage and transportation of two-stage formed tire blanks for tires, and the storage and transportation of giant engineering tires for two-stage formed blanks. Affect tire quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

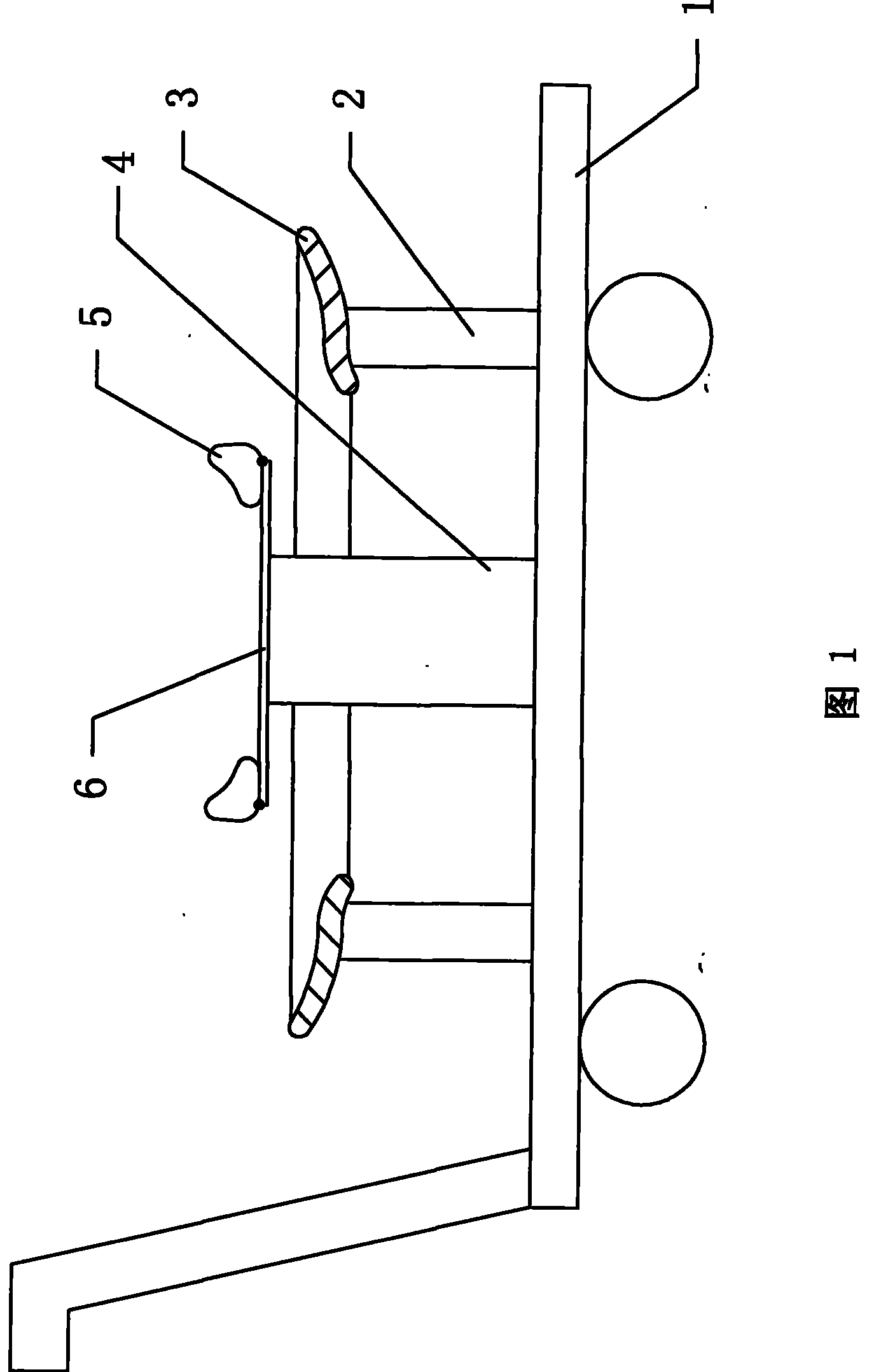

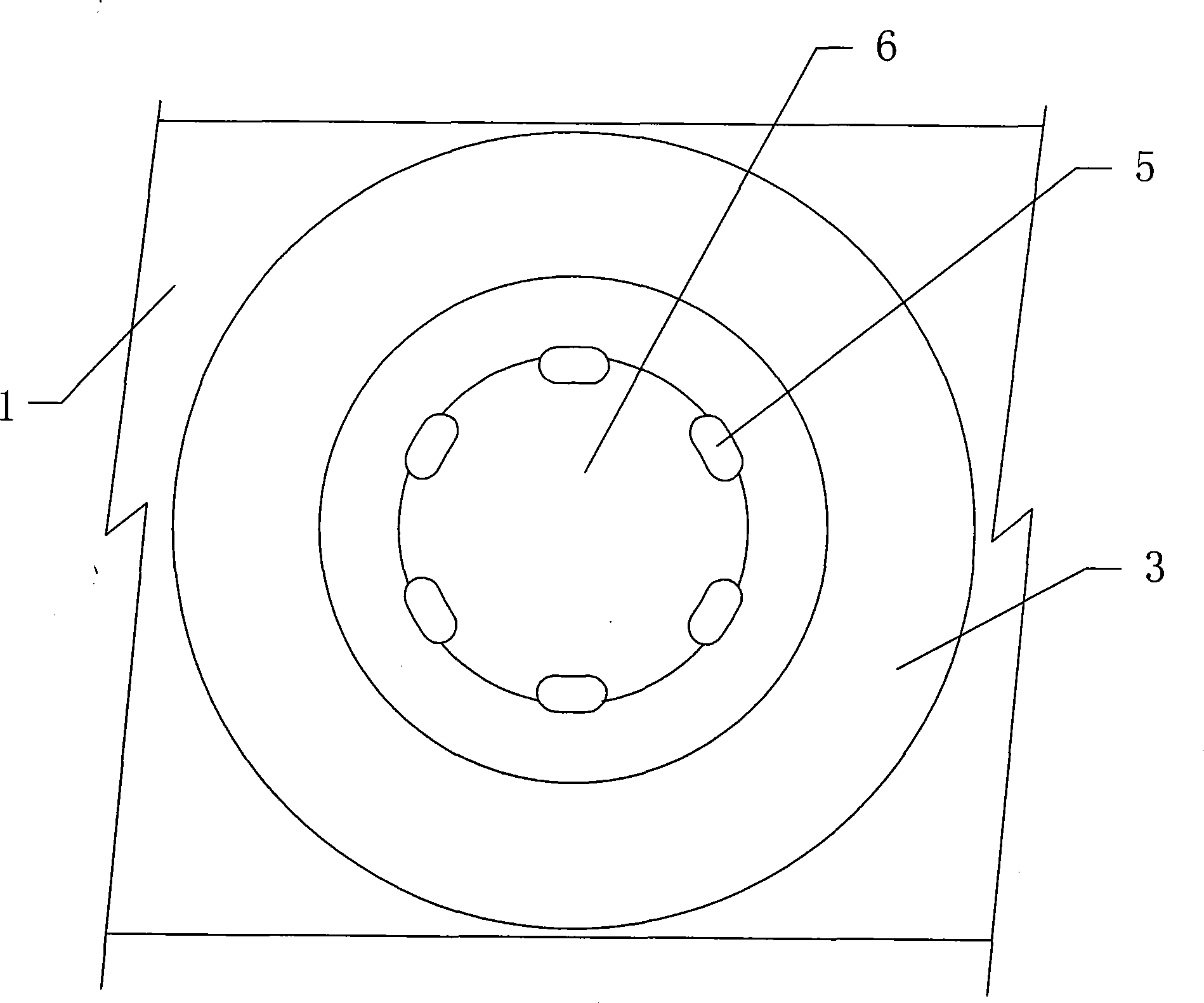

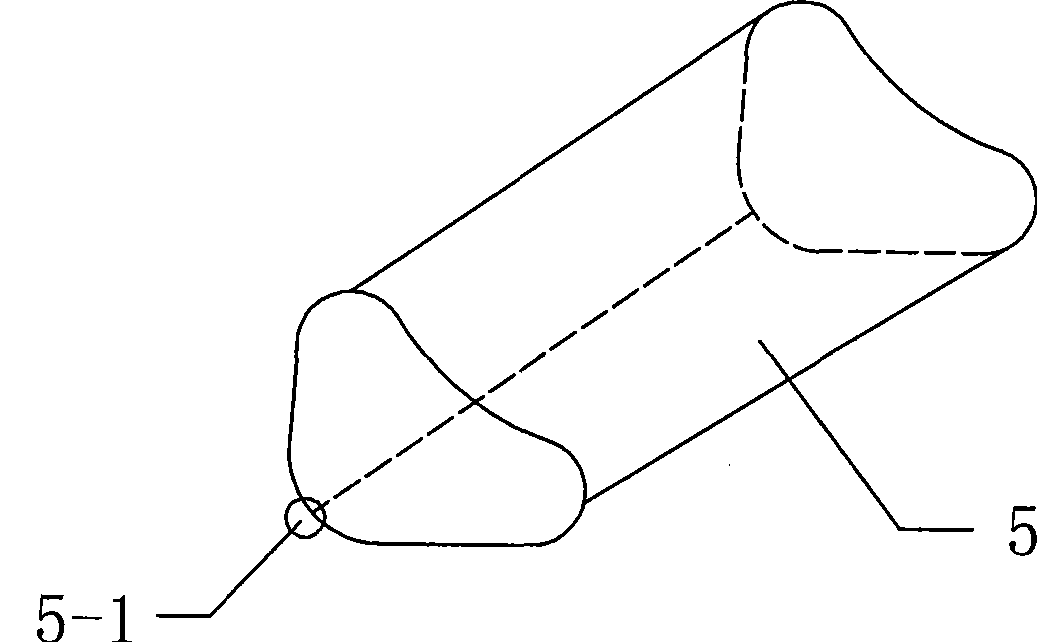

[0016] The structure of the embodiment of the tire two-stage forming blank storage vehicle of the present invention is as follows figure 1 , 2 As shown, a support 2 is fixedly installed on the car body 1 equipped with pneumatic tire walking rollers, and the support 2 is fixedly connected to and supports the annular tray 3 on it. The diameter of the inner hole of the tray 3 is greater than the diameter of the green bead, and its outer diameter is equal to Or larger than the outer diameter of the green tire. The height of the support 2 is greater than the height of the outer warping of the lower rim of the tire blank. The support 2 is four pillars, and the inner diameter of the ring formed by the pillars is larger than the bead diameter of the green tire 7 . A lifting mechanism 4 is installed on the car body 1 below the inner hole of the tray 3. The lifting mechanism 4 is a hydraulic mechanism, and the top of the piston rod is fixed with a circular bracket 6. 6 upper sub-mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com