Electronic unit of textile machine for producing across winding reel

A technology of cross-winding bobbins and electronic units, which is applied in the direction of continuous winding spinning machines, spinning machines, textiles and papermaking, etc., to achieve the effect of reducing laying costs, reducing quantities, and saving additional expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

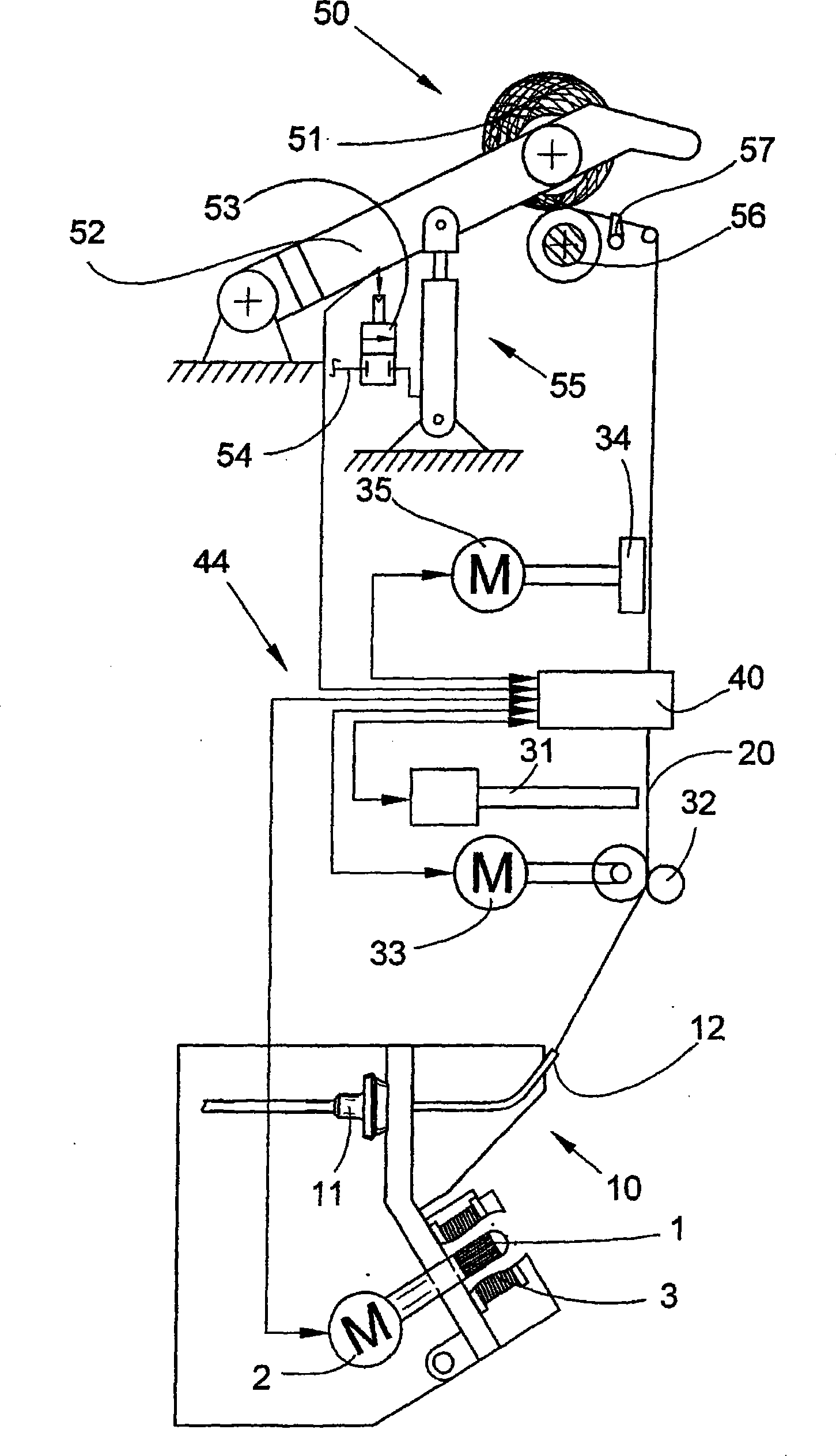

[0026] figure 1 A schematic diagram showing the rotor spinning machine according to the present invention. The fiber bundle (not shown here) is conveyed by the fiber bundle feeding drum 1 to the fiber bundle opening roller 3. In this case, the fiber bundle feeding drum 1 is driven by the feeding motor 2. The opened fiber bundle is fed into a spinning tank 10 with a spinning cup 11. In the illustrated embodiment, the spinning cups are driven intensively by a belt (not shown) transmission, in other words, the spinning cups of a plurality of workstations are simultaneously driven by a central drive. However, as an option, a single electric drive can also be used for the spinning cup.

[0027] The yarn 20 is drawn from the spinning tank 10 by the yarn drawing nozzle 12 and is transported forward to the winding device 50 through the yarn drawing device 32 driven by the drawing motor 33. The suction device 31 used in the splicing process is also arranged above the yarn drawing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com