LED light fitting

A technology of LED lamps and LED light sources, which is applied in the direction of damage prevention measures for lighting devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc., and can solve problems such as affecting service life, poor air circulation, and LED damage. Achieve large heat dissipation area, excellent heat dissipation effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

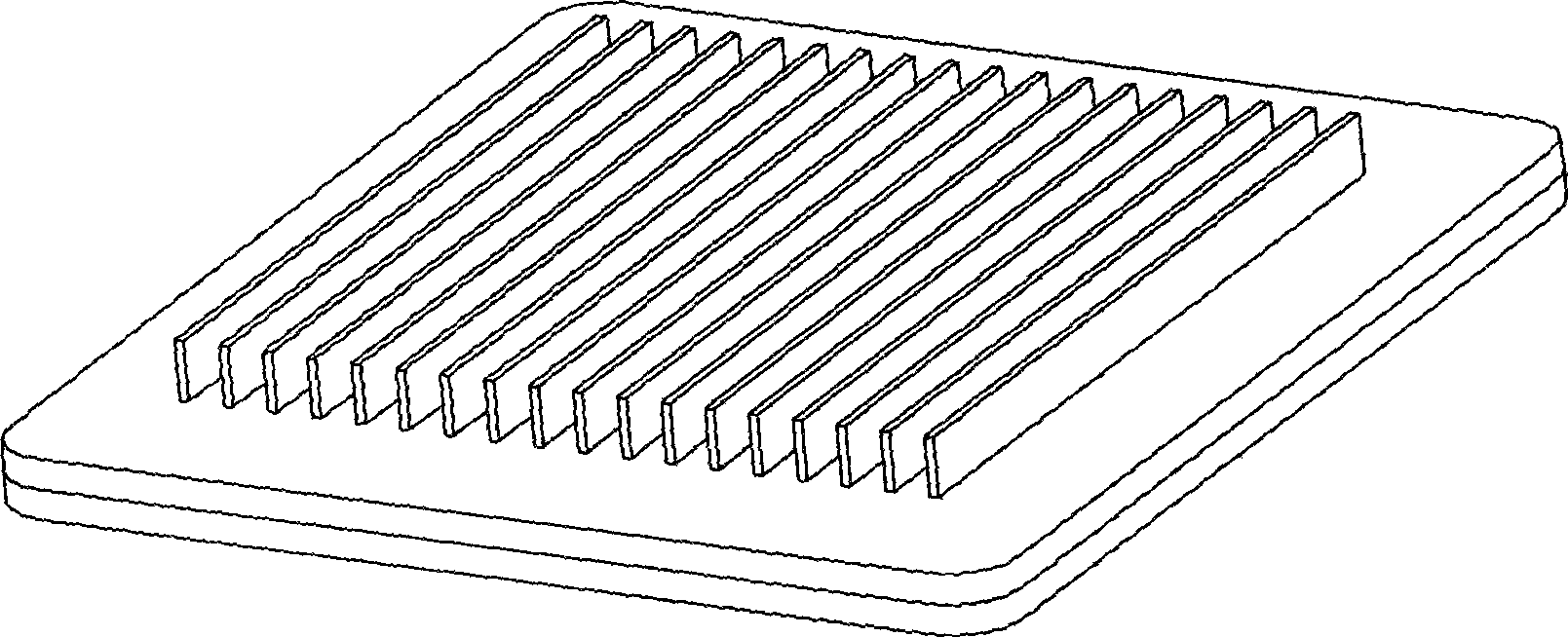

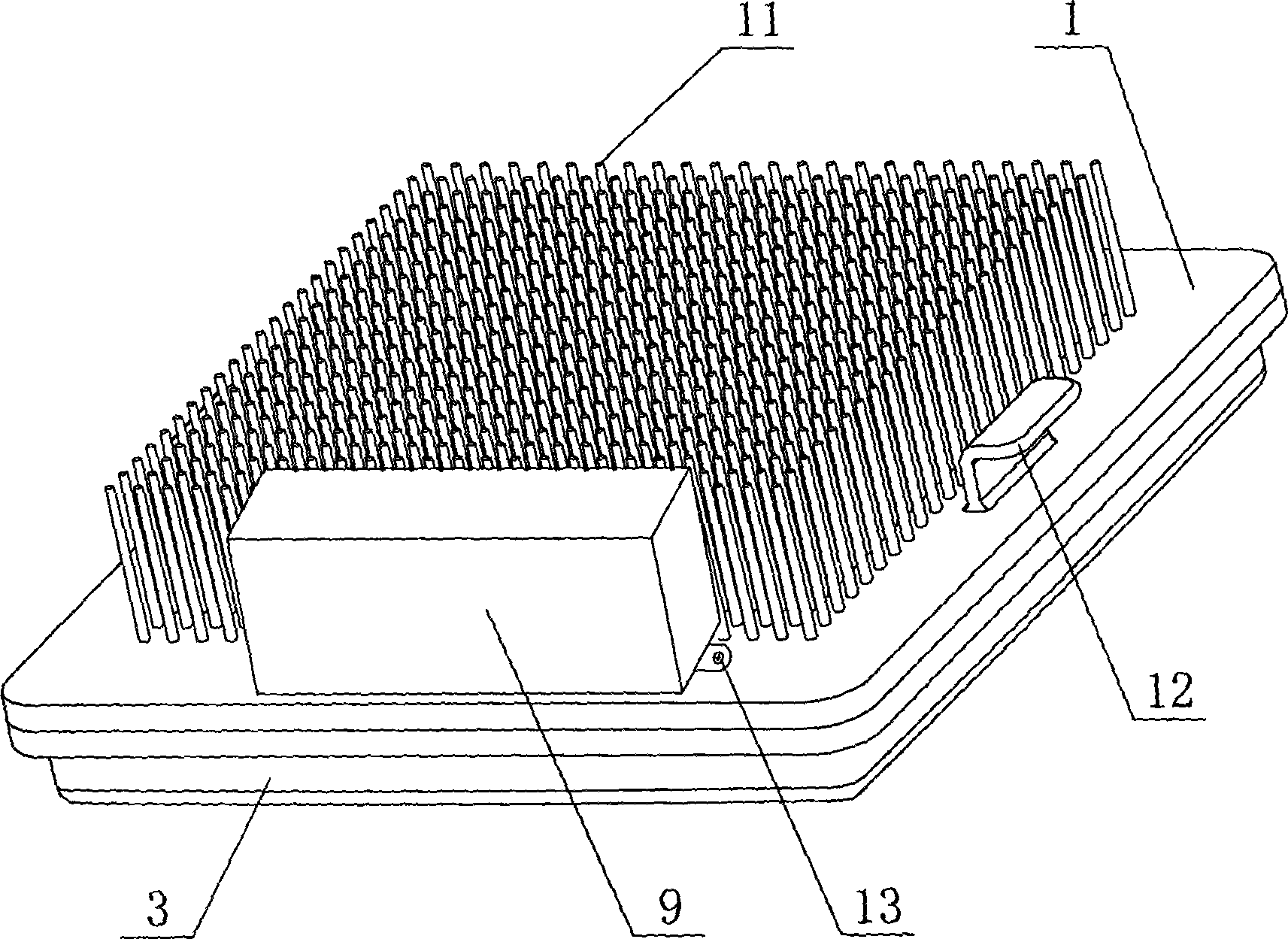

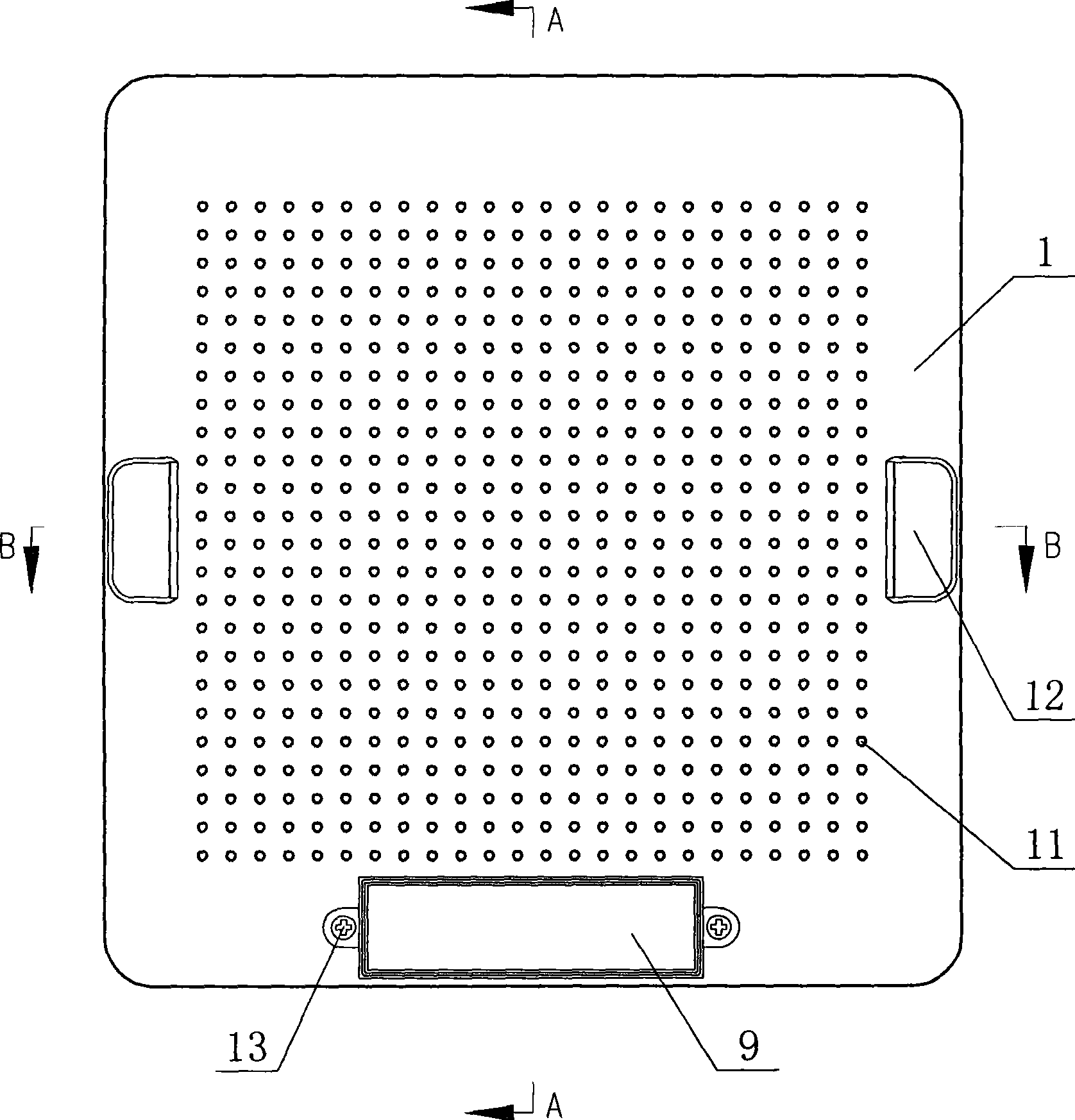

[0022] Such as Figure 2 to Figure 7 As shown, the LED lamp of this embodiment includes a heat dissipation substrate 1, an LED light source assembly 2, a light-transmitting protective cover 3, a reflector 4, a drive assembly 7, and a power supply protection box 9. The LED light source assembly 2 includes several LEDs 21 and circuits The heat dissipation bottom plate 22, the LED light source assembly 2 is fixedly connected with the heat dissipation substrate 1 and conducts heat to the heat dissipation substrate 1 through the circuit heat dissipation bottom plate 22, the light-transmitting protective cover 3 and the heat dissipation substrate 1 576 heat dissipation rods 11 and two handle-shaped lamp installation parts 12 are arranged on the back of the heat dissipation substrate 1. The heat dissipation rods 11 are arranged in a matrix array of 24×24. The heat dissipation substrate 1 The thickness is 5mm, the diameter of the heat dissipation rod 11 is φ3mm, the height of the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com