Optical sheet and uses thereof

A technology of optical plates and substrates, applied in optics, optical components, nonlinear optics, etc., can solve problems such as dark lines of lamp tubes, increase the thickness of backlight modules, increase the number and cost of lamp tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

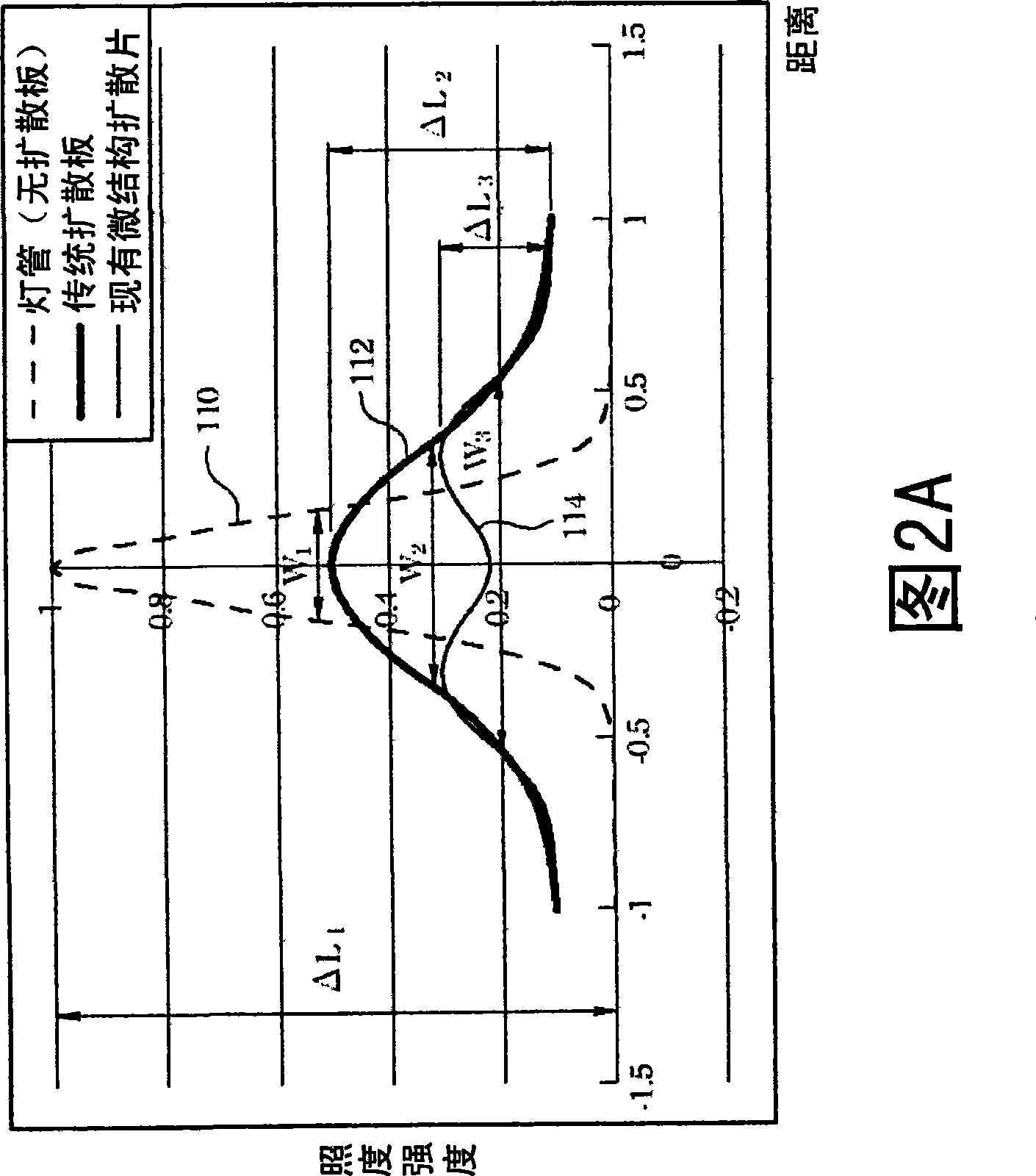

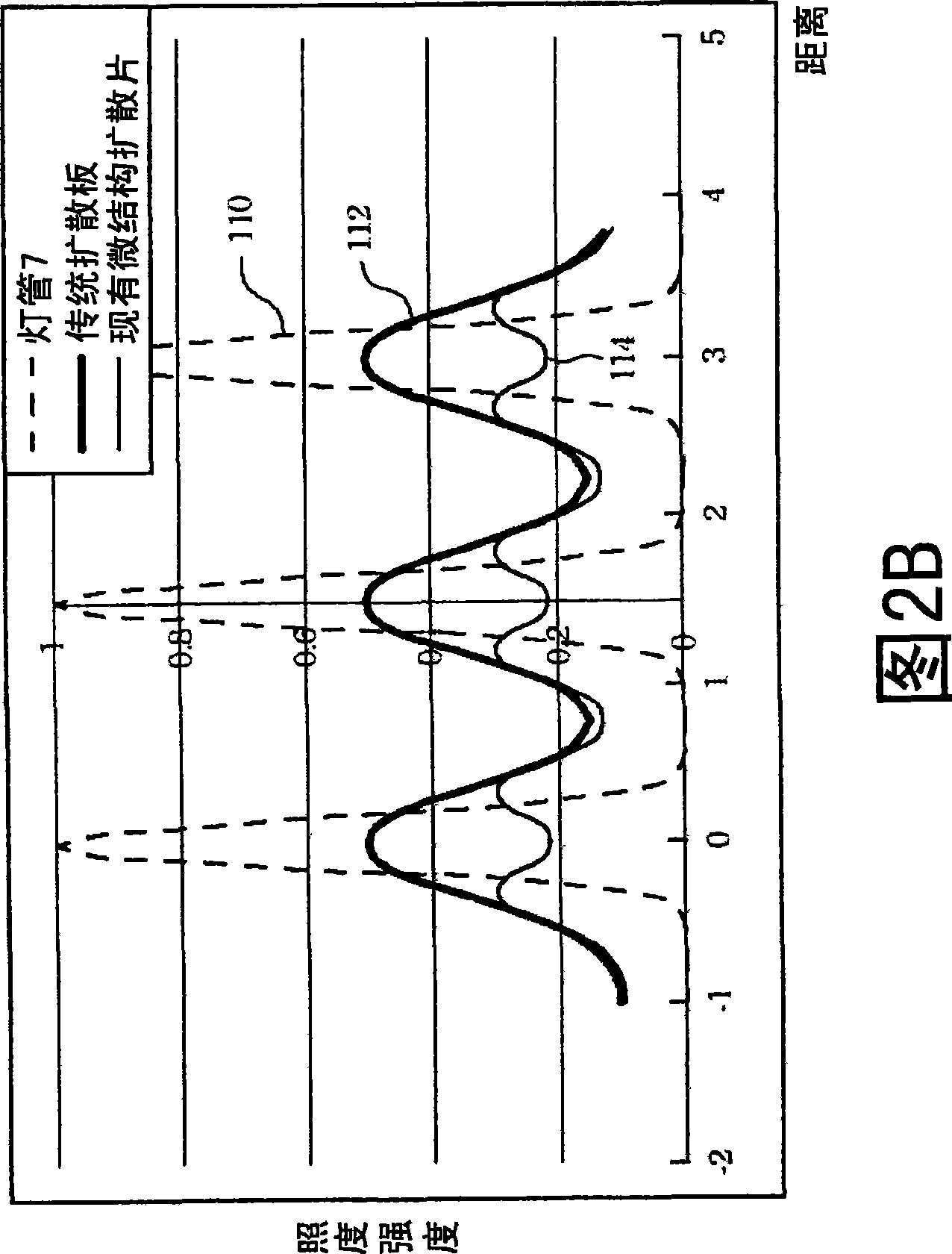

[0031] The invention discloses an optical plate and its application, which can greatly improve the uniformity of the illuminance distribution of the outgoing light of the light source, increase the illuminance of the backlight module, reduce the number of light sources of the backlight module, reduce the cost, and reduce the number of backlight modules and the thickness of the LCD. In order to make the description of the present invention more detailed and complete, reference may be made to the following description in combination with the diagrams of FIGS. 3 to 14 .

[0032] FIG. 3 shows a cross-sectional view of an optical plate according to a preferred embodiment of the present invention. The optical plate 200 mainly includes a substrate 202 , a plurality of polygonal convex structures 204 and diffusion particles 220 . The polygonal convex structures 204 are disposed on the surface 206 of the substrate 202 , and the particles 220 are dispersed in the substrate 202 and all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com