Coiling framework, motor and method for coiling motor stator

A technology of winding skeleton and stator iron core, which is applied in the manufacture of motor generators, the shape/style/structure of winding conductors, electrical components, etc., and can solve problems such as affecting motor reliability, motor short-circuit, and motor burnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

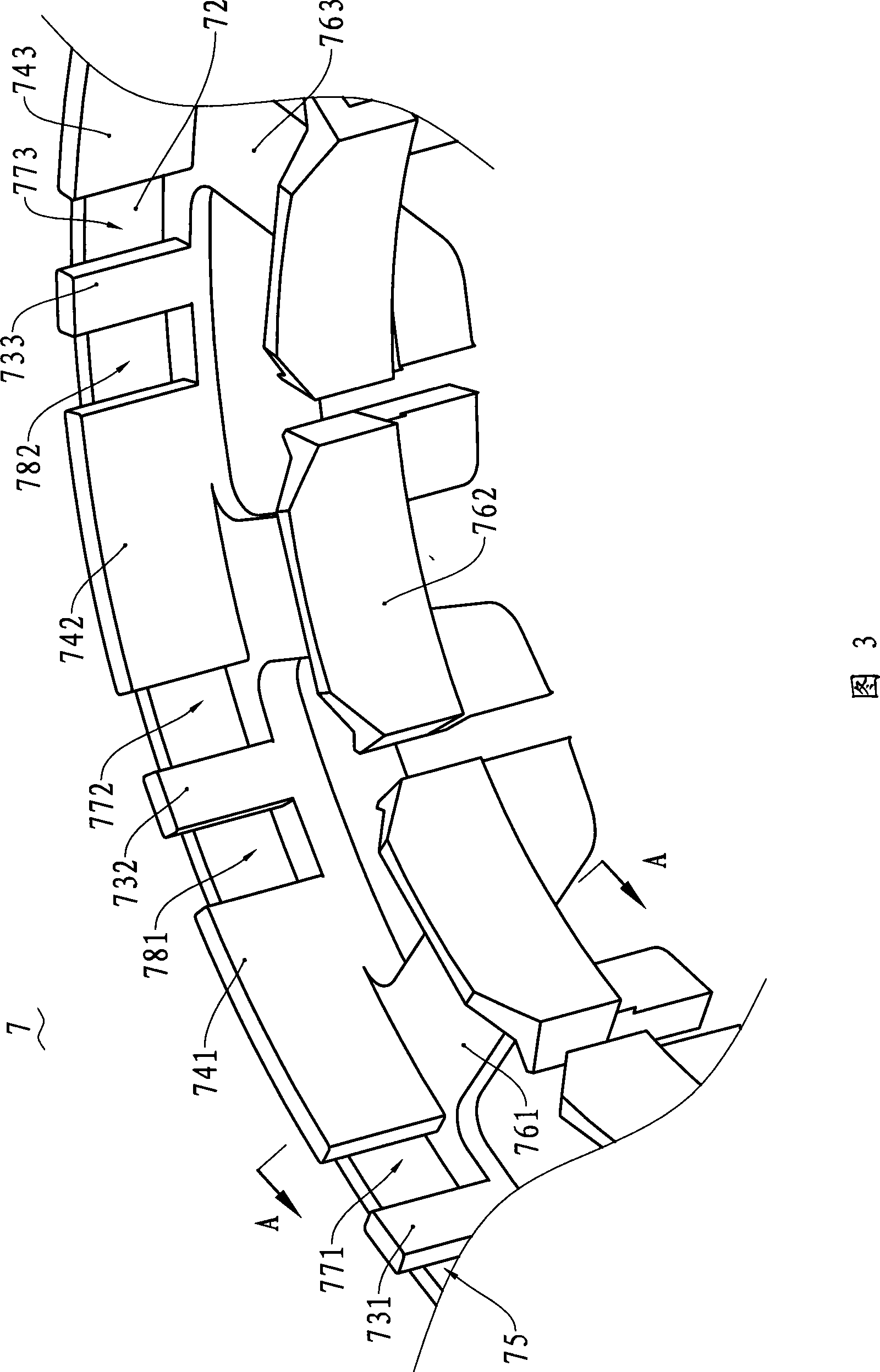

[0037] Embodiment of winding skeleton:

[0038] Referring to FIG. 5 , it is a front view of an embodiment of the winding bobbin of the present invention, in which coils of various phases are wound on the winding bobbin. In this embodiment, the winding frame 8 has an annular columnar frame made of insulating material, and a ring plate 82 extending outward along the axial direction of the frame body is provided on the outer edge of one end of the frame body. There are a plurality of bosses 831, 832, 833 distributed along the circumferential direction, the bosses extend outward along the axial direction of the frame body, and the number of bosses is equal to the number of magnetic poles of the stator core, and each boss is connected to a corresponding to the magnetic poles. For example, in this embodiment, the boss 831 corresponds to the U-phase magnetic pole, the boss 832 corresponds to the V-phase magnetic pole, and the boss 833 corresponds to the W-phase magnetic pole. Moreo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com