Artificial hair, wig having artificial hair and method of producing artificial hair

A technology of artificial hair and manufacturing method, applied in the direction of wigs, single-component polyester artificial filaments, clothing, etc., which can solve problems such as difficult mixing, poor hygroscopicity, and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Next, embodiments of the present invention will be described in detail.

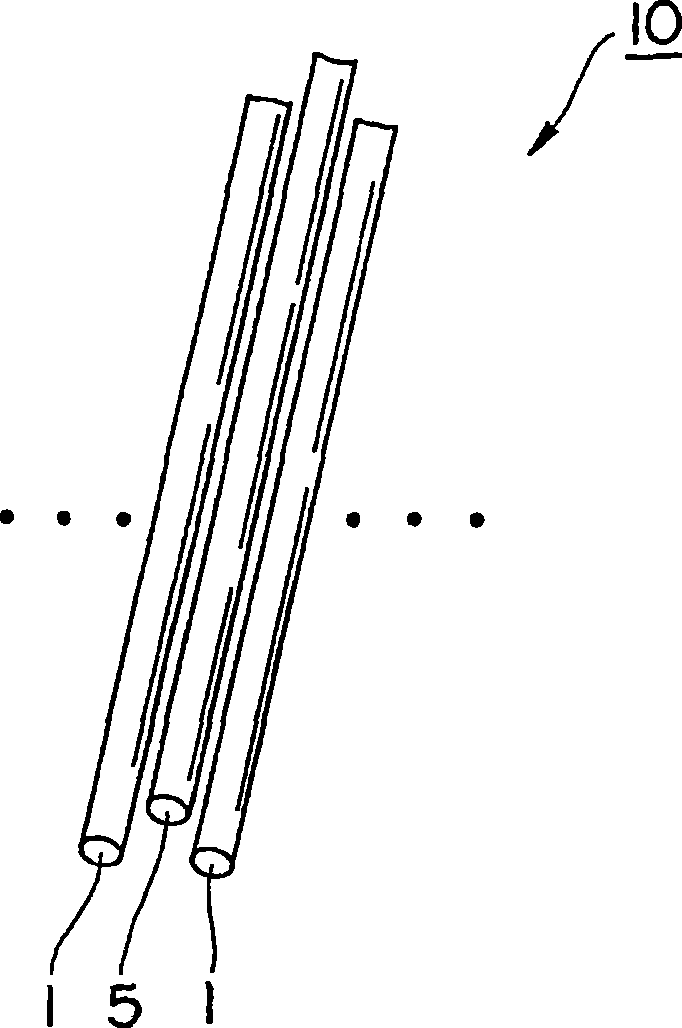

[0129] Artificial hair containing polyethylene terephthalate as a component was manufactured using a spinning machine 30 shown in FIG. 8 . As a raw material for artificial hair, pellets of polyethylene terephthalate (manufactured by Toyobo Co., Ltd., density 1.40 g / cm 3 , melting point is 255°C) and a coloring resin based on polyethylene terephthalate resin and black, yellow, orange, and red pigments in weight percents of 6%, 6%, 5%, and 5% respectively pellets.

[0130] The spinning conditions were such that the melting temperature of the pellets was 270° C. as the discharge temperature from the discharge port, and the discharge port was equipped with a nozzle having 15 holes with a diameter of 0.7 mm. The temperature of the warm bath 33 was 40°C.

[0131] Regarding stretching conditions, the speeds of each of the first stretching rolls 34 to 4th stretching rolls 40 were adjusted so that the a...

Embodiment 2

[0139] Except for changing the stretching conditions, it carried out similarly to Example 1, and produced the artificial hair whose cross-sectional size had an average diameter of 50 micrometers.

Embodiment 3

[0141] Except for changing the stretching conditions, it carried out similarly to Example 1, and produced the artificial hair whose cross-sectional size had an average diameter of 55 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com