Discharge valve assembly for linear compressor

A technology of linear compressors and discharge valves, which is applied to components of pumping devices for elastic fluids, engine components, control valves, etc., can solve problems such as increased noise, and achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will now be described in detail with reference to the accompanying drawings.

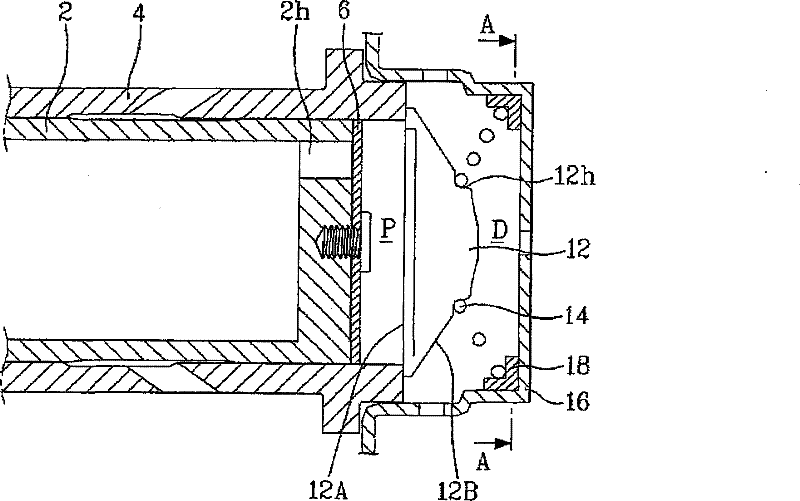

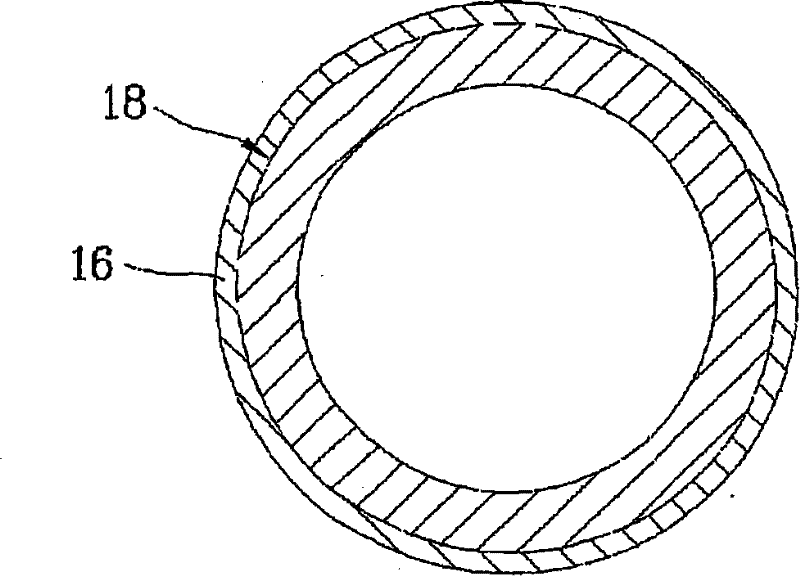

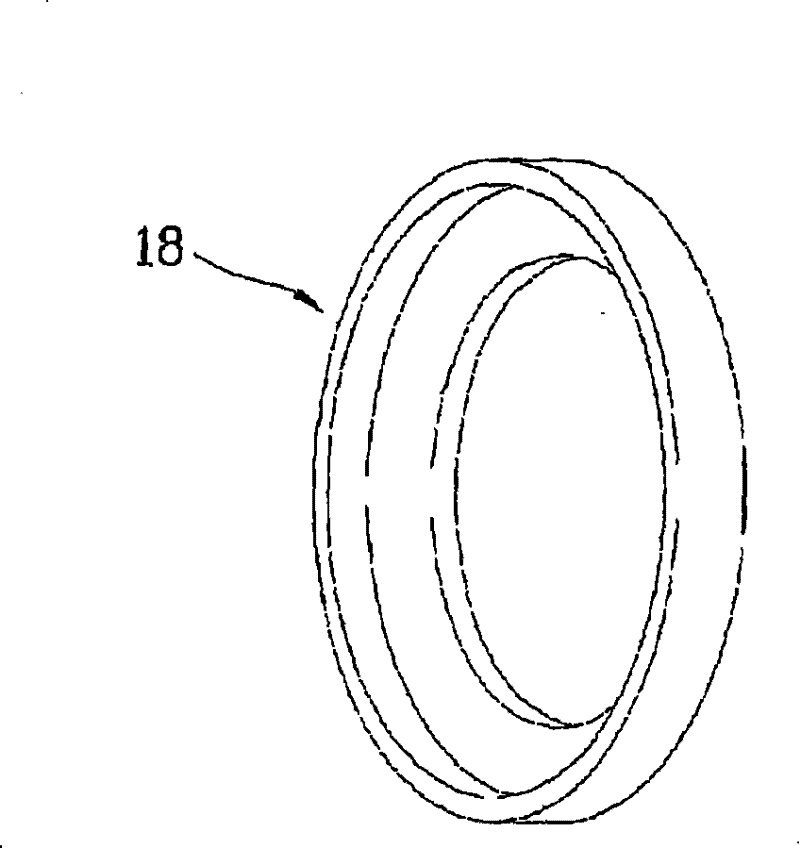

[0033] Figure 4 is a side sectional view illustrating a discharge valve assembly for a linear compressor according to the present invention; Figure 5 is along Figure 4 A sectional view taken along the line B-B of ; and Image 6 is a perspective view illustrating a discharge valve support applied to a discharge valve assembly for a linear compressor according to the present invention.

[0034] Such as Figure 4As shown, in a discharge valve assembly for a linear compressor, a piston 52 reciprocates linearly within a cylinder 54 to compress the refrigerant. At one end of the cylinder 54 is mounted a discharge valve 62 for opening and closing the cylinder 54 . At one end of the cylinder 54 is fixedly mounted a discharge cover 66 for covering the cylinder 54 and the discharge valve 62 . One end of the helical discharge valve spring 64 elastically supports the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com