Folding roller of paper processing apparatus

A technology for folding roller pairs and paper, which is applied in the direction of thin material handling, folding thin materials, transportation and packaging, etc., and can solve problems such as folding corners, increased thickness, poor delivery of folding rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

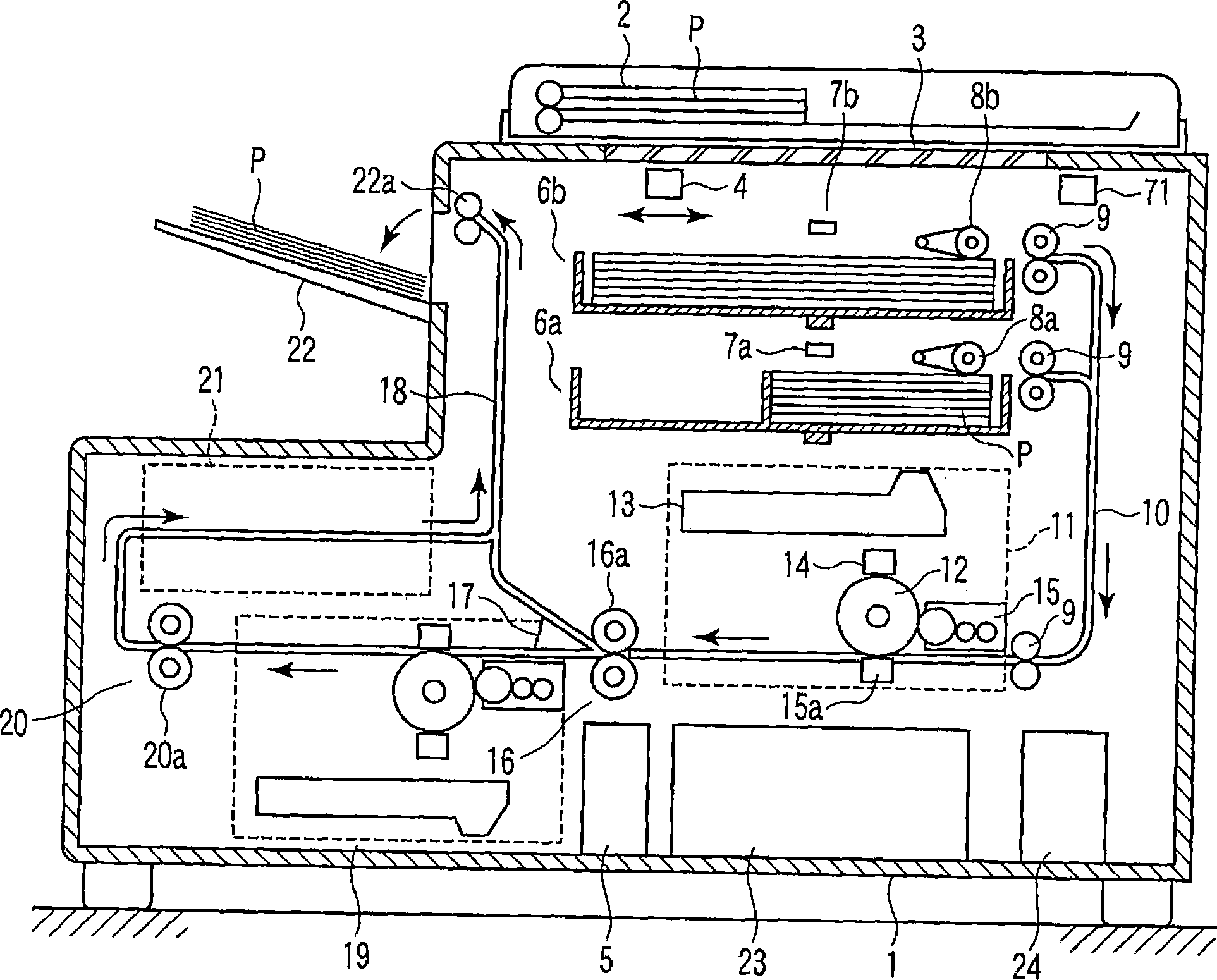

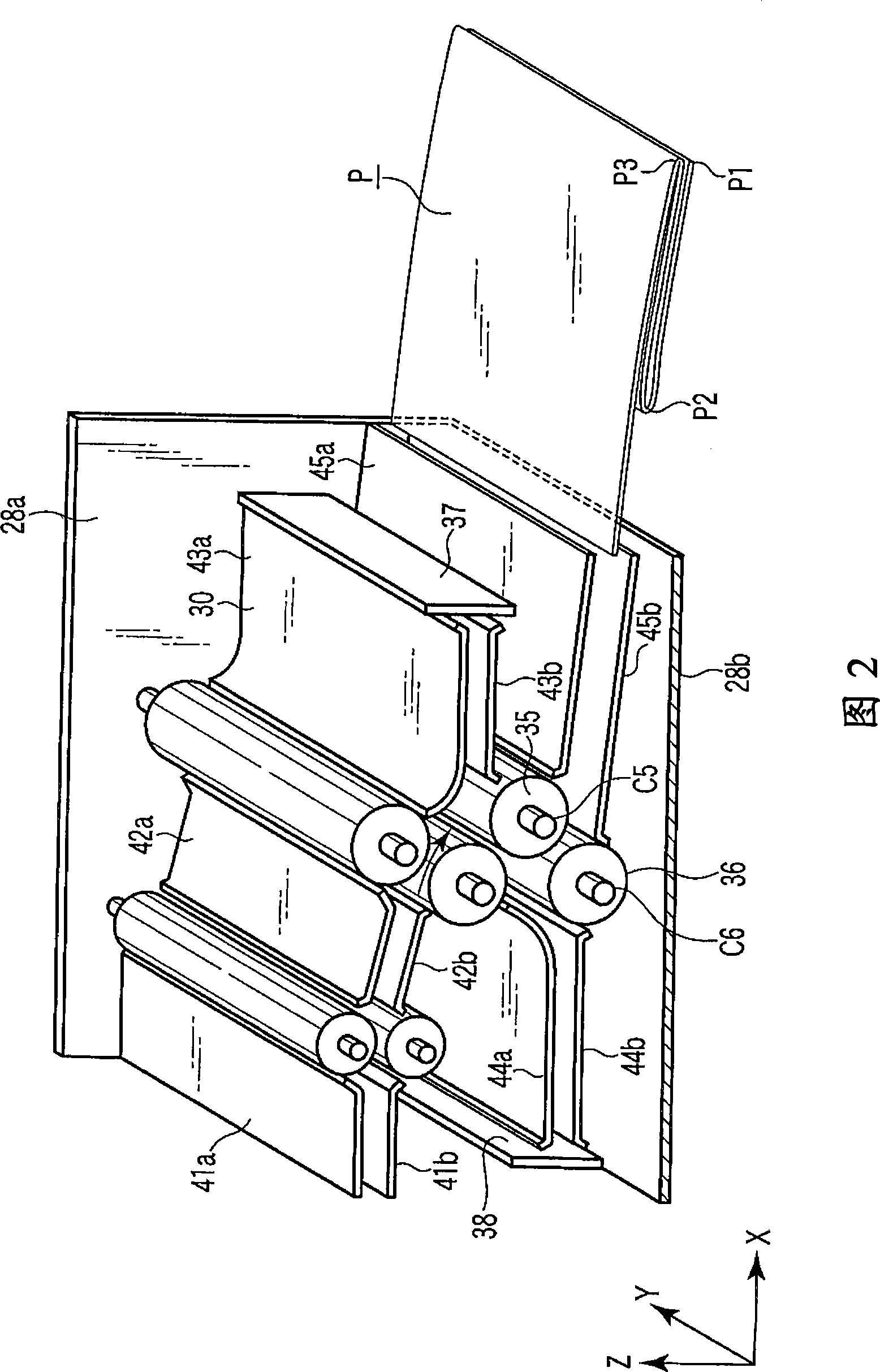

[0036] figure 1 A schematic configuration of an electrophotographic digital copier equipped with the Z-fold mechanism 21 according to this embodiment is shown.

[0037] The digital copier has a housing 1 as its housing. A document table 3 made of transparent glass is provided on the upper surface of the housing 1, and a document supply unit 2 is provided thereon. The document supply unit 2 conveys a plurality of documents one by one to a predetermined position on the document table 3 . Below the document table 3 is provided a scanner 4 that moves left and right in the figure. Image data read from a document by the scanner 4 is stored in a data file device 5 provided near the lower end of the housing 1 .

[0038]Below the scanner 4 are provided two paper cassettes 6 a , 6 b which are detachable with respect to the housing 1 for storing paper. Transmissive optical sensors 7a, 7b for detecting the presence or absence of paper P, and supply rollers 8a, 8b for separating and se...

no. 2 example

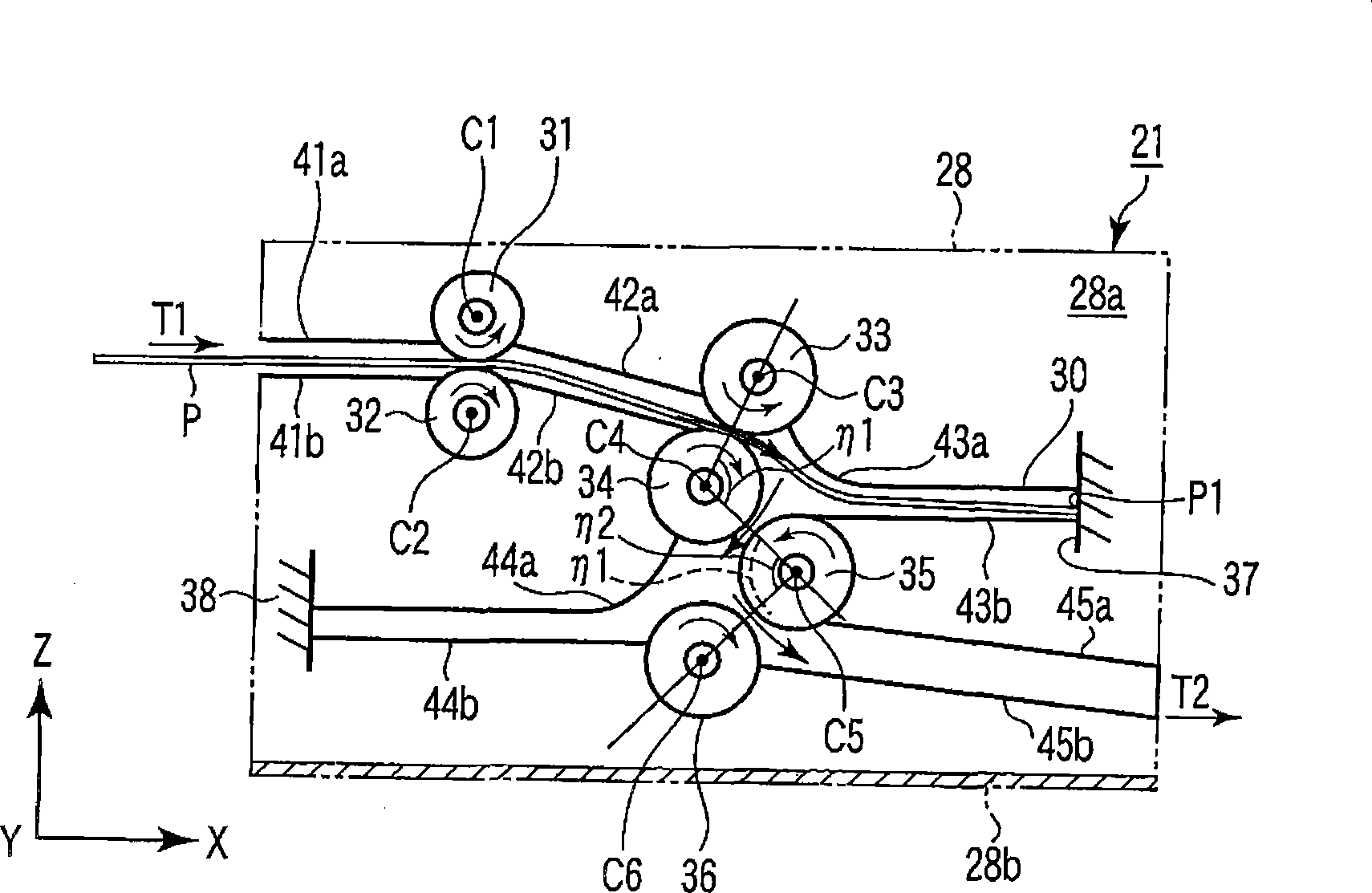

[0074] Below, refer to Figure 8 , the Z folding mechanism 21 of the second embodiment of the present invention will be described. Since this embodiment is the same as the above-mentioned first embodiment except for the configuration of the roller pair, the same reference numerals are assigned to the same parts, and description thereof will be omitted. In the drawings, the paper is thickened and the nip between the roller pairs is enlarged and opened for the sake of explanation, but actually the rollers are in contact with each other.

[0075] In the Z folding mechanism of the present embodiment, the diameters of the plurality of rollers 33-36 are different according to the positions, and when the radii of the conveying rollers 33-36 are r3-r6 respectively, r3<r4<r5<r6. The conveying speeds of the rollers opposite to the rollers 33-36 are equal. For example, when the motors are used in common and the roller diameters are different from each other, the gear ratio is set so th...

no. 3 example

[0083] Below, refer to Figure 10 , the Z folding mechanism of the third embodiment of the present invention will be described. This embodiment is the same as the above-mentioned first embodiment except that the auxiliary mechanisms 60 and 65 are provided, and therefore description of the same parts will be omitted. In the drawings, the paper is thickened and the nip between the roller pairs is enlarged and opened for the sake of explanation, but actually the rollers are in contact with each other.

[0084] Such as Figure 10 As shown, in the Z-folding mechanism 21 of this embodiment, the auxiliary mechanisms 60 and 65 for assisting the bending deformation of the paper are arranged at two folding positions. The conveying speeds of the rollers 33-36 in this embodiment are equal.

[0085] The auxiliary mechanism 60 includes: an abutment member 61, which is pressed by the paper when the front end of the conveyed paper abuts against it; a connecting member 62, which is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com