Vibration motor and lens drive mechanism

一种振动电机、振动体的技术,应用在发电机/电动机、压电效应/电致伸缩或磁致伸缩的电动机、电气元件等方向,能够解决分散、无法驱动效率降低、加压机构按压力不稳定等问题,达到稳定驱动传递力、抑制传递不良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the vibration motor and the lens drive mechanism according to the present invention will be described.

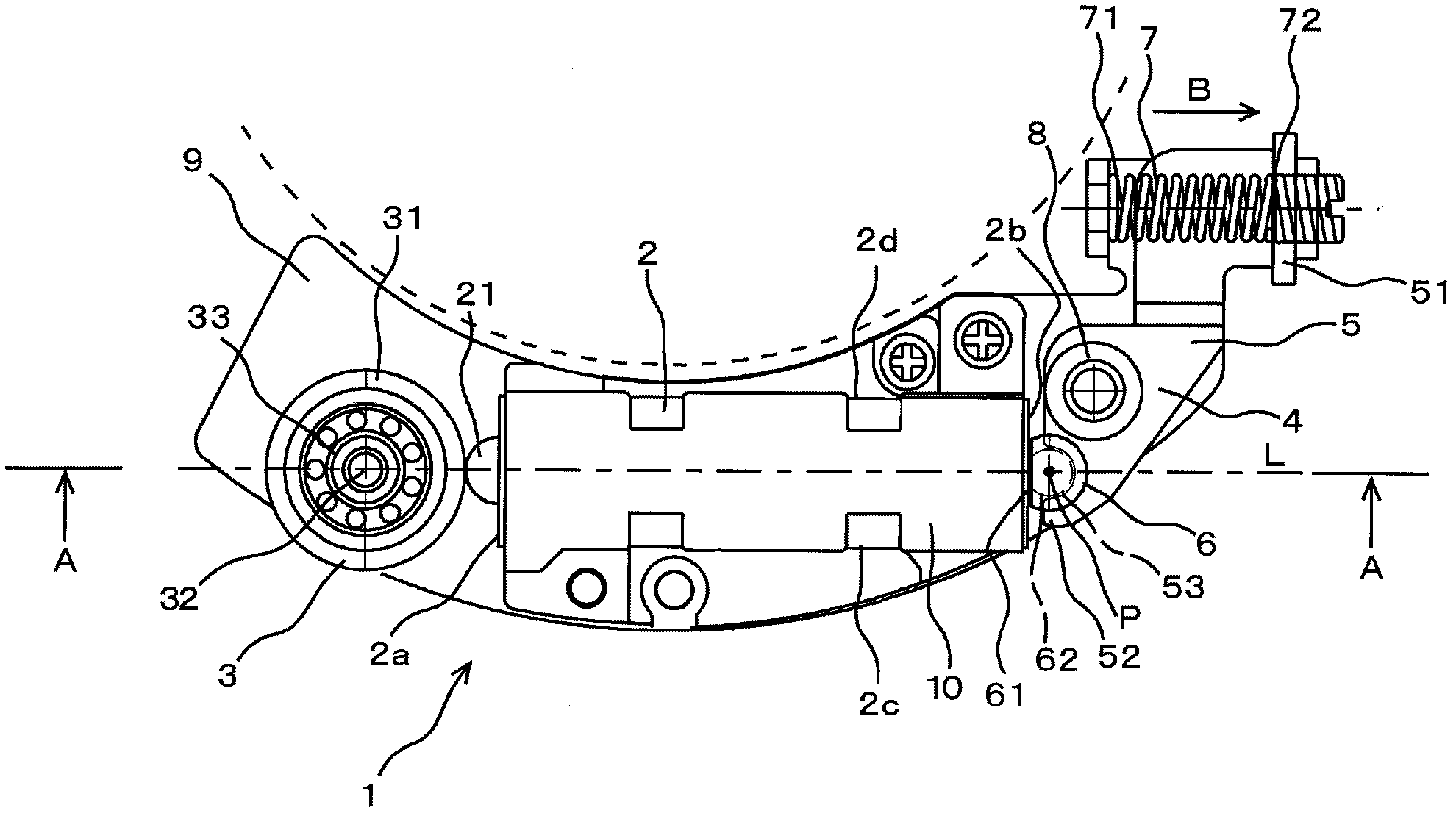

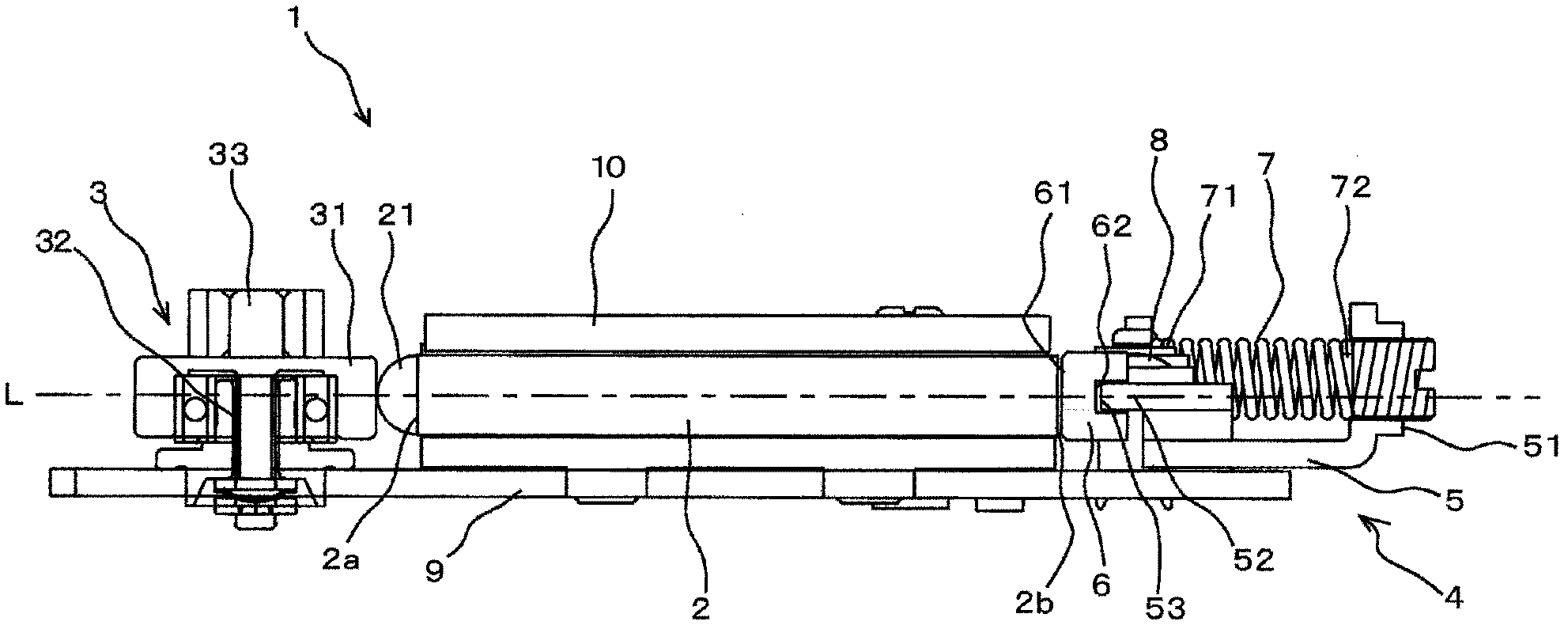

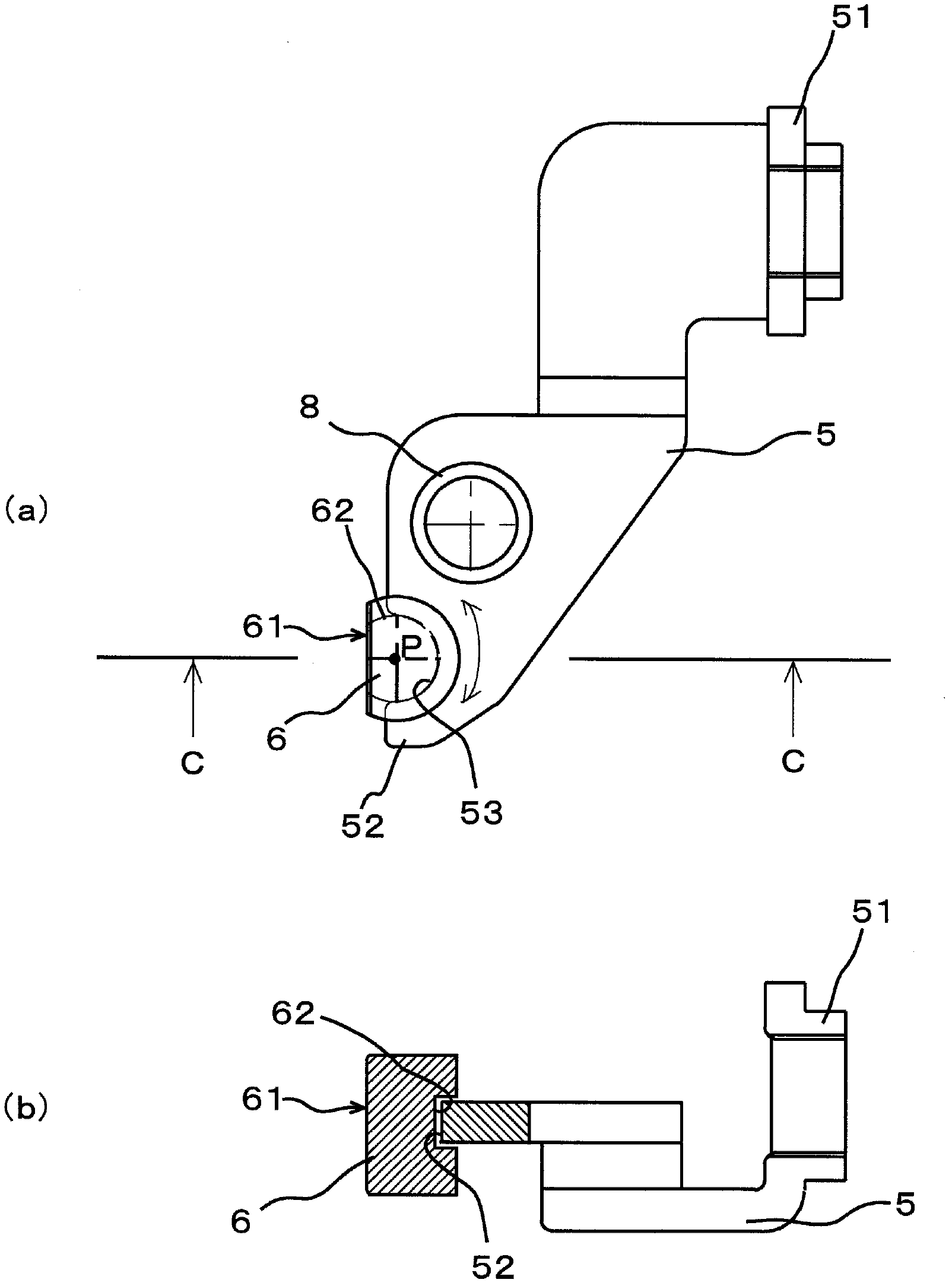

[0025] The vibration motor according to the present invention vibrates a vibrating body, presses the vibrating body to a driven body, and transmits the vibration of the vibrating body as a driving force, and includes a vibrating body and a pressurizing mechanism. figure 1 It is a plan view showing an example in which the vibration motor according to the present invention is arranged on the outer peripheral side of the lens as a driving mechanism of the imaging lens. figure 2 to include figure 1 Front view including section A-A in . Such as figure 1 and figure 2 As shown, in the vibrating body 2 of the vibrating motor 1, the output part 21 provided on the side surface 2a at one end thereof is disposed at a position abutting against the driven body 3, and is abutted against the side surface 2b at the other end side. A pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com